Chapter 16 PLC Function Applications│CP2000

16-3

16-2 Notes before PLC use

1. The PLC has a preset communications format of 7, N, 2, 9600, with node 2; the PLC node can

be changed in Pr.09-35, but this address may not be the same as the drive's address setting of

Pr.09-00.

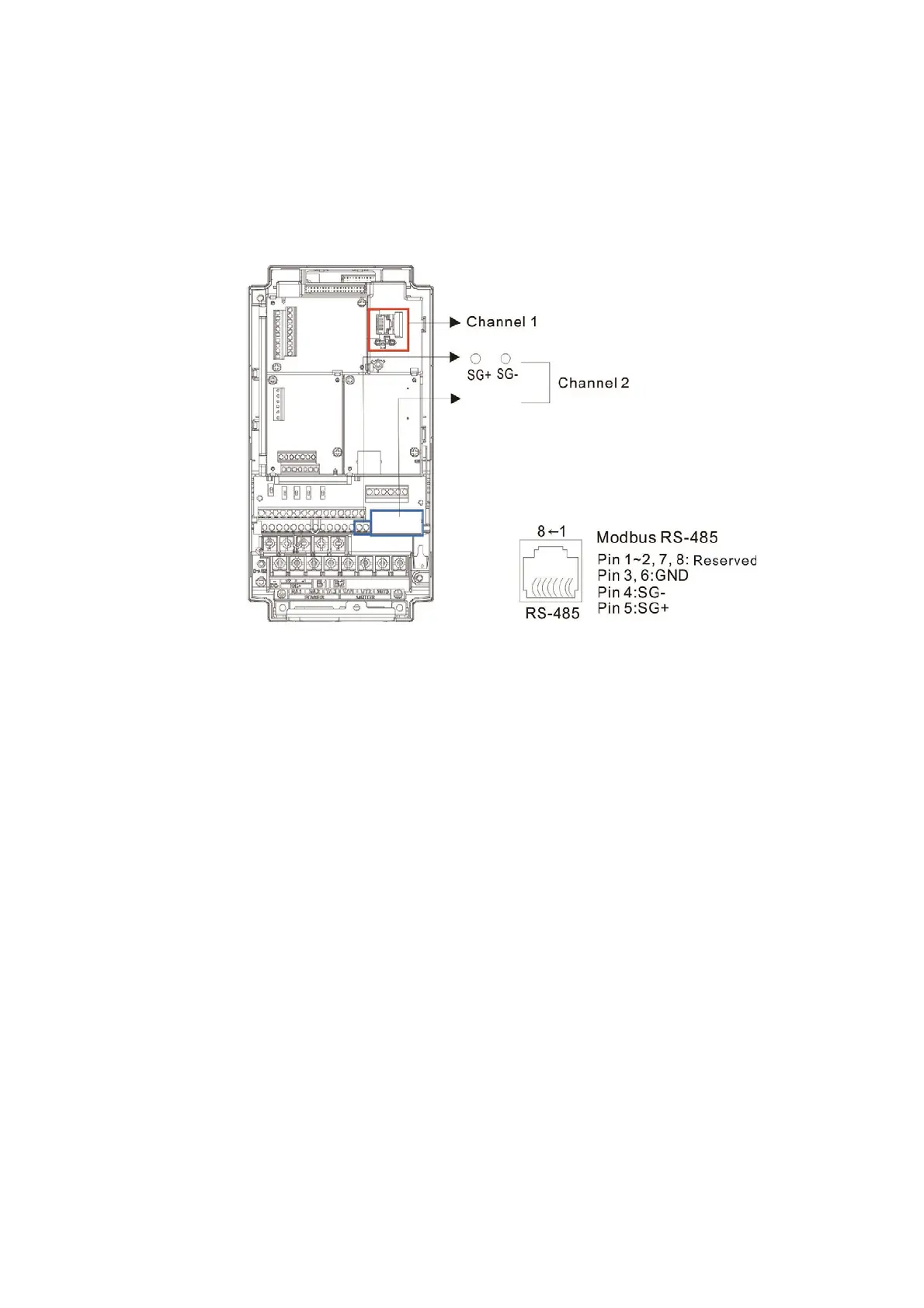

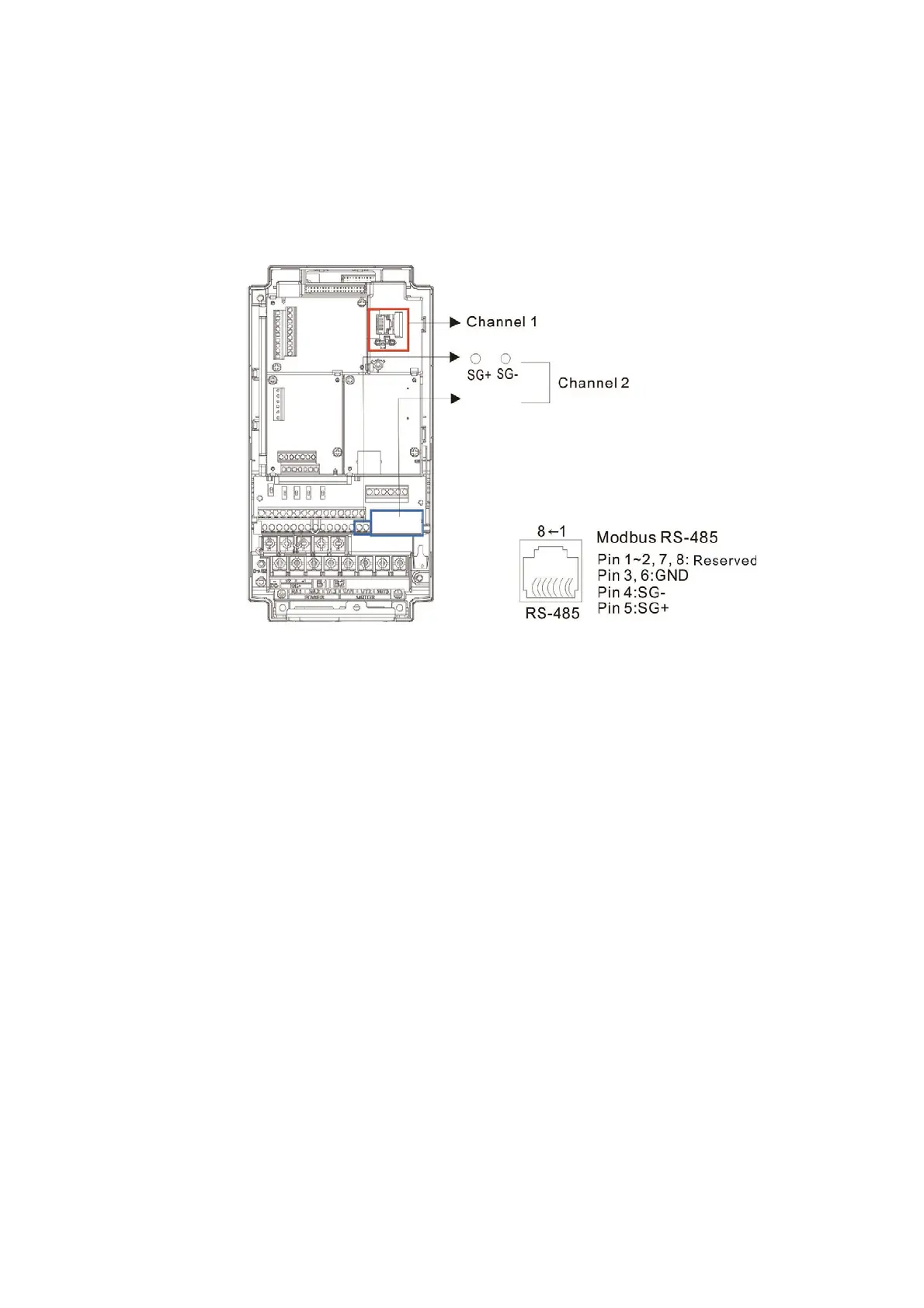

2. The CP2000 provides 2 communications serial ports that can be used to download PLC

programs (see figure below). Channel 1 has a fixed communications format of 19200, 8, N, 2

RTU.

3. The client can simultaneously access data from the converter and internal PLC, which is

performed through identification of the node. For instance, if the converter node is 1 and the

internal PLC node is 2, then the client command will be

01 (node) 03 (read) 0400 (address) 0001 (1 data item), indicating that it must read the data in

converter Pr.04-00.

02 (node) 03 (read) 0400 (address) 0001 (1 data item), indicating that it must read the data in

internal PLC X0

4. The PLC program will be disabled when uploading/ downloading programs.

5. Please note when using WPR commands to write in parameters, values may be modified up to

a maximum of 10

9

times, otherwise a memory write error will occur. The calculation of

modifications is based on whether the entered value has been changed. If the entered value is

left unchanged, the modifications will not increase afterwards. But if the entered value is

different from before, the number of modifications will increase by one. Those parameters listed

below are exceptions, please proceed to the next page for details:

Pr.00-11 Speed control mode

Pr.01-12–01-19 Acceleration / Deceleration time 1–4

Pr.02-12 Multi-function input mode selection

Pr.02-18 Multi-function output direction

Pr.04-50–04-59 PLC buffer 0–9

Pr.08-04 Upper limit of integral control

Pr.08-05 PID output command limit

Loading...

Loading...