C-110-170-200E R11 Page 13

Troubleshooting

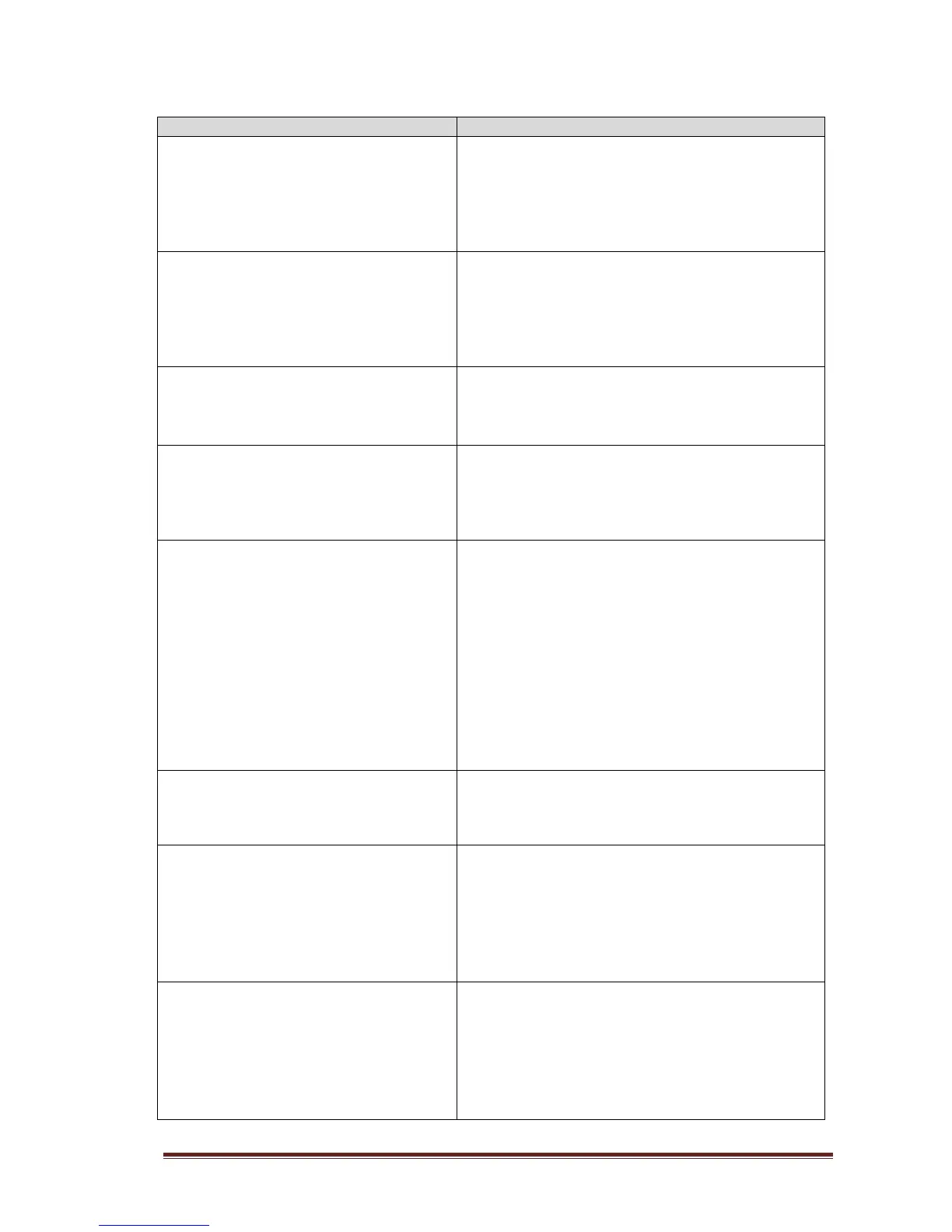

Symptom Rectification

Main switch is turned on the High Pressure

Cleaner will not run.

Check power supply connection for faulty

components

• Make sure the socket is inserted correctly

• Check if fuse is blown, replace if necessary.

Motor is humming & Pump does not give

pressure or low pressure

Voltage is too low as compare to specification.

(Check main voltage)

• Motor phase is missing (For 3 phase application).

Check the connection box voltage with a meter

• High-pressure pump is blocked

Pump pressure drops and the High Pressure

Cleaner works irregularly

Strain filter is clogged.

• Water supply from the tap is insufficient.

• Clean the strain water filter

Pump continuously stops and starts, when

the spray-gun trigger is activated.

The high pressure nozzle is partly clogged.

Turn off the High Pressure Cleaner, dismantle the

high-pressure nozzle and remove the extraneous

matter. Replace if damaged

High pressure cleaner does not reach the

proper working pressure when the spray-

gun handle is activated

The high-pressure nozzle is clogged.

• Dirt in the by-pass valve.

• The pump sucks air.

• Turn off the High Pressure Cleaner. Clean the

nozzle.

• Inspect the low pressure supply, while spray-gun

trigger is activated, ON the machine on again.

• Repeat the procedure again; now with the trigger

released. If the problem still occurs, by-pass valve

should be dismantled and the extraneous matter

removed.

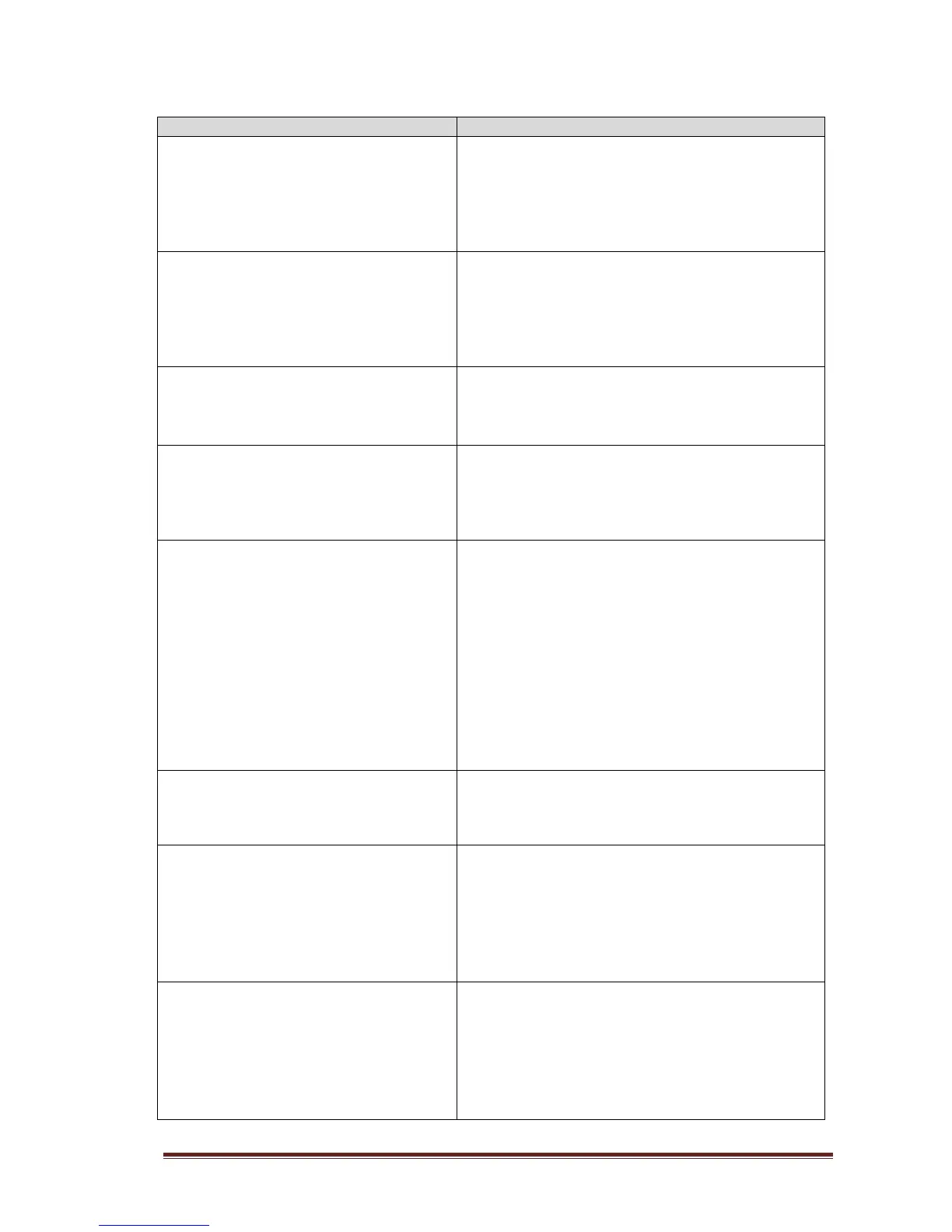

High Pressure Cleaner only works with

approximately 2/3 of the maximum

pressure, and the high-pressure hose is

vibrating.

Valves are dirty

• Remove the dirt and check to ensure the valve flaps

are movable and fit tightly.

Noisiness

The pump sucks air.

• One or more valve springs are broken or down.

• Extraneous matter in the valves.

• Crankcase or motor bearings worn out.

• Inspect the low-pressure supply. Replace springs.

• Clean the valves. Replace the bearings.

Water in the oil

The O-ring casing is worn out.

• High moisture in the air (condensing inside the

crankcase)

• The seals are completely worn out.

• Check or replace the O-ring.

• Renewal of the crankcase oil more often.

• Replace the seals.

Loading...

Loading...