15 © 2014 Finishing Brands UK Ltd.

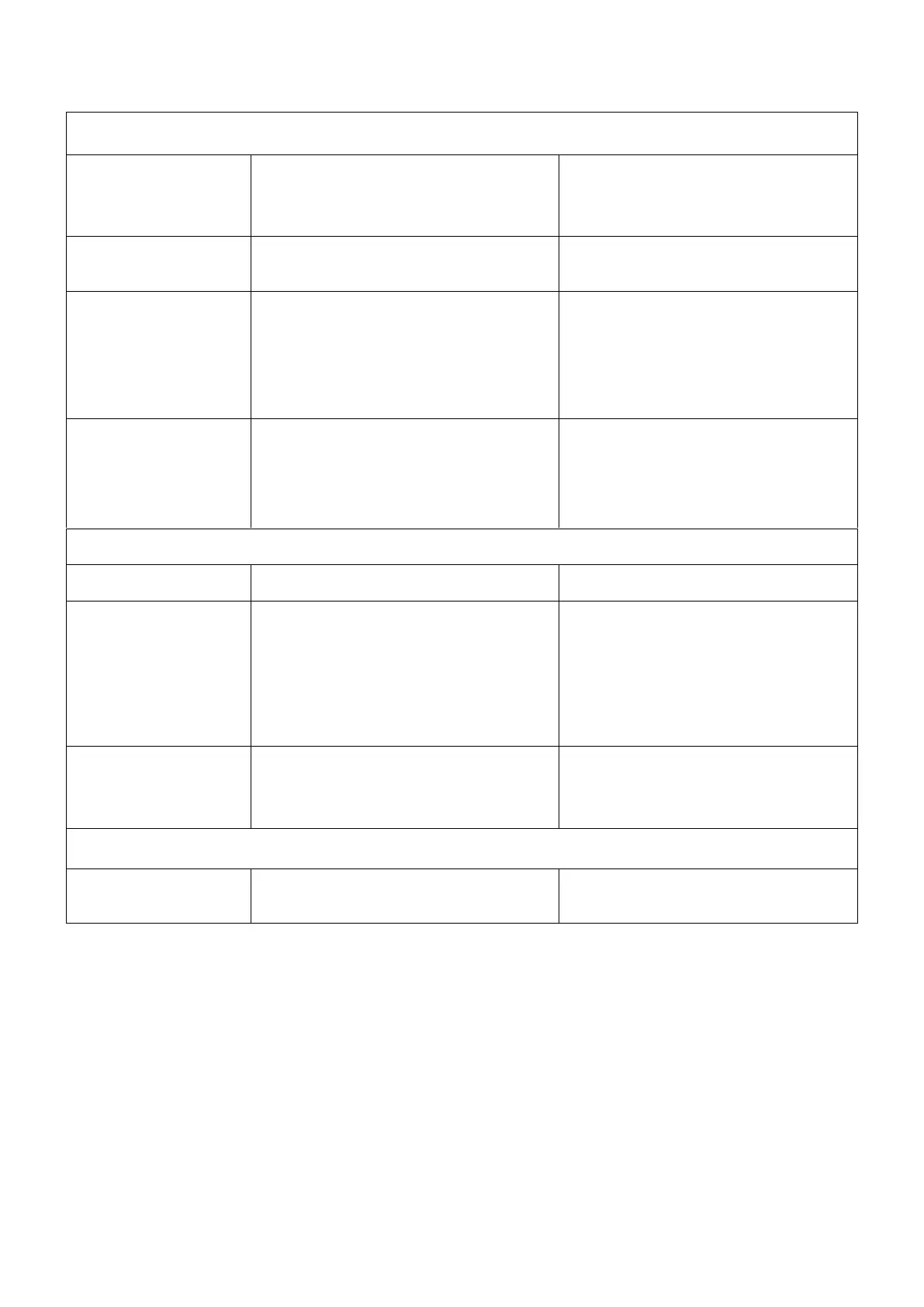

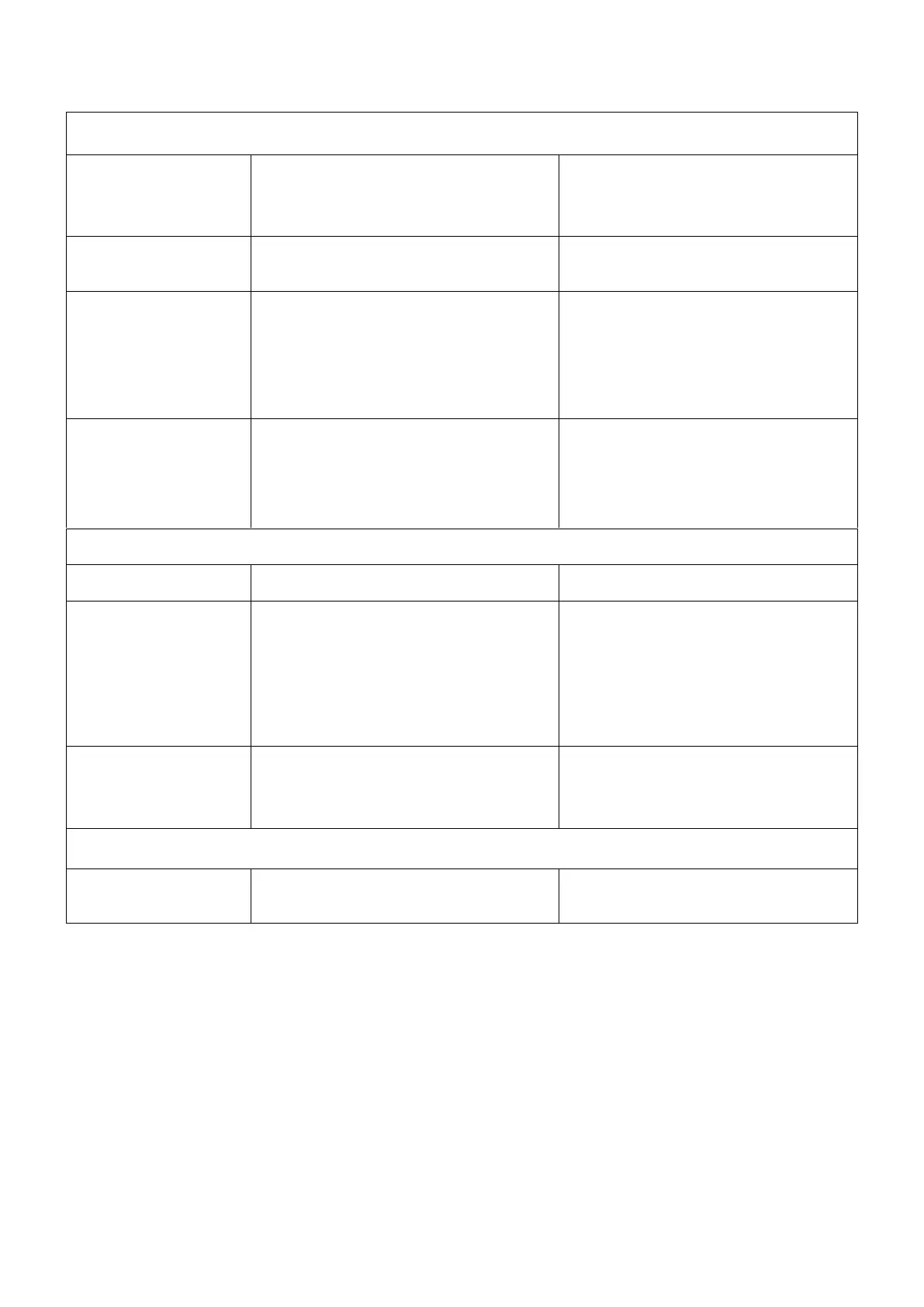

Possible Problems in Operation (cont.)

Fluid Starved spray

pattern.

Inadequate material flow.

Increase Fluid Flow.

Change to larger fluid nozzle size.

Check hose for blockage.

Air pressure too high.

Gun too far from work surface.

Reduce air pressure.

Adjust to correct target distance.

Air pressure too high.

Gun too far from work surface.

Gun motion too fast.

Fluid flow too low.

Reduce air pressure.

Adjust to correct distance.

Slow down.

Increase Fluid Flow or use larger nozzle

size.

Too much material flow.

Material too thin.

Motion too slow.

Reduce Fluid Flow or change to smaller

fluid nozzle and fluid needle size.

Mix correctly or apply light coats.

Increase Gun Traverse speed.

Fluid leaking from

Detection hole.

Packing or Fluid Needle worn.

Fluid leaking or dripping

from front of gun.

Fluid nozzle or fluid needle worn or

damaged.

Foreign matter in fluid nozzle.

Fluid needle dirty or stuck in needle

packing.

Wrong size fluid needle or fluid nozzle.

Replace fluid nozzle and fluid needle.

Clean.

Clean.

Replace fluid nozzle and fluid needle.

Fluid leaking between

the Spray Gun and the

Manifold.

O-Rings damaged or missing.

Torx screw not tight.

Replace O-Rings using kit SPA-412-K.

Tighten Torx screw or replace using kit

SPA-411-K.

Spray Gun is loose

when assembled onto

Manifold.

Tighten Torx screw 1.8-2.0 Nm (1.3-1.5

lbf.ft) or replace using kit SPA-411-K.

Loading...

Loading...