ENGLISH

23

WARNING: Do not attempt to tighten or loosen drill

bits (or any other accessory) by gripping the front part

of the chuck and turning the tool on. Damage to the

chuck and personal injury mayoccur.

The rotary hammer can be fitted with various chisel bits

depending on the desired application. Use sharp drill

bitsonly.

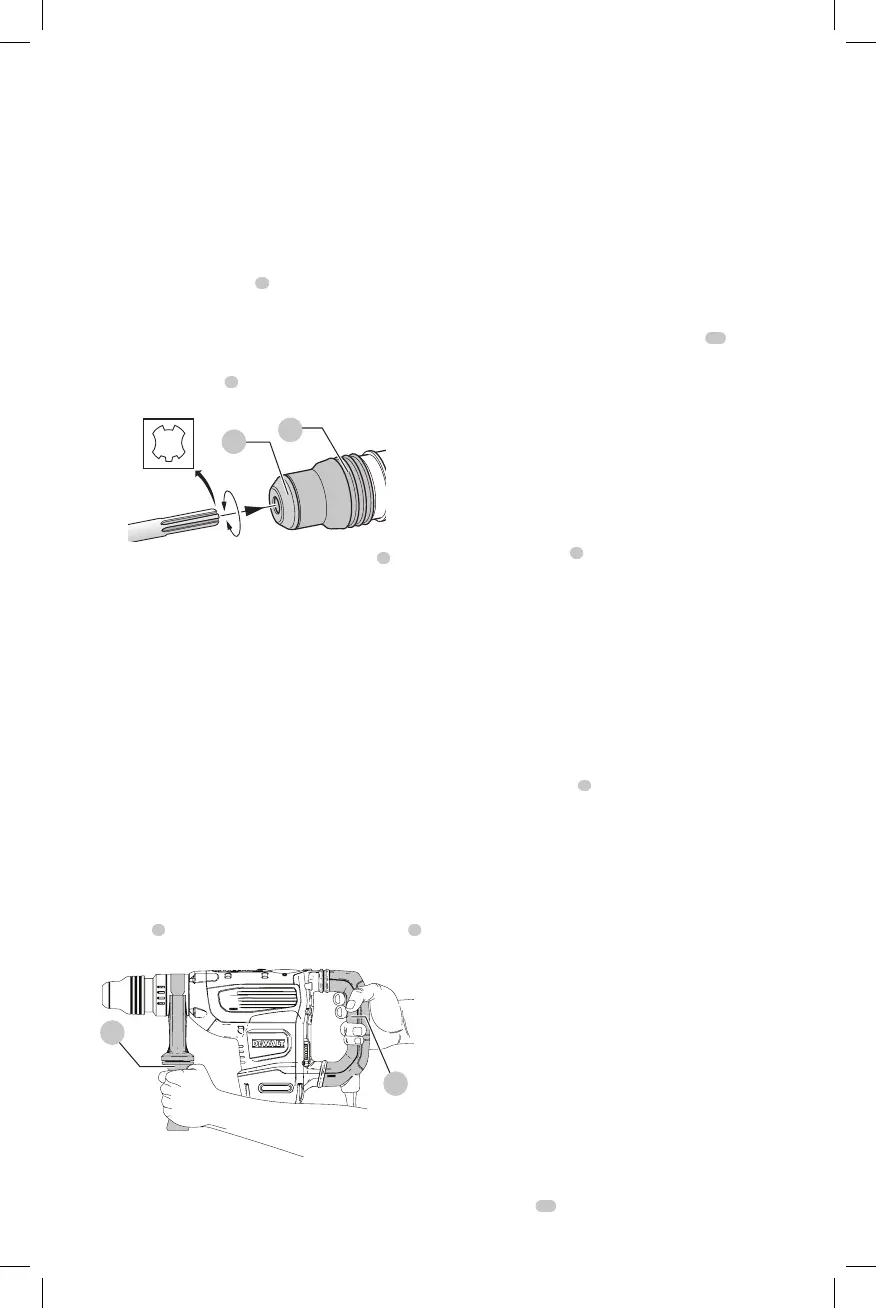

Inserting and Removing SDS MAX Bits

(Fig. C)

1. Insert bit in the bit holder

6

and apply downward

pressure while rotating to secure the bit into place. The

bit shank must beclean.

2. Ensure the bit is properlyengaged.

NOTE: The bit needs to move several centimeters in and

out of the bit holder

6

when properlyengaged.

6

7

Fig. C

3. To remove the bit, pull back the locking sleeve

7

and

pull the bitout.

OPERATION

WARNING: Always observe the safety instructions

and applicableregulations.

WARNING: To reduce the risk of serious personal

injury, turn unit off and disconnect it from

power source before making any adjustments or

removing/installing attachments or accessories.

An accidental start-up can causeinjury.

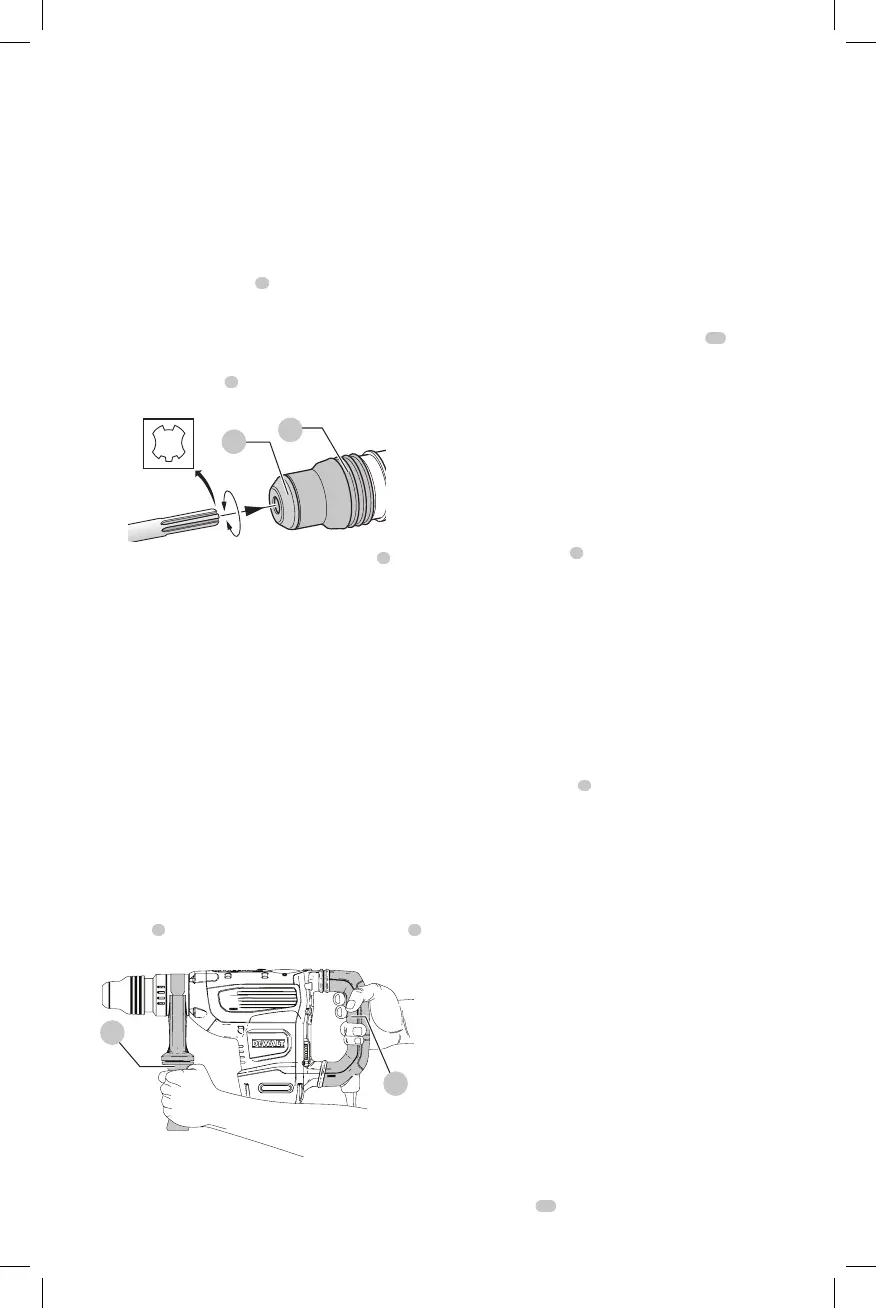

Proper Hand Position (Fig. D)

WARNING: To reduce the risk of serious personal injury,

ALWAYS use proper hand position as shown.

WARNING: To reduce the risk of serious personal

injury, ALWAYS hold securely in anticipation of a

suddenreaction.

Proper hand position requires one hand on the mounted

side handle

2

, with the other hand on the mainhandle

5

.

Fig. D

2

5

SHOCKS Active Vibration Control®

System

For best vibration control, hold the tool as described in

Proper Hand Position and apply just enough pressure so

the damping device on the main handle is approximately

mid stroke. The hammer only needs enough pressure to

engage the active vibration control. Applying too much

pressure will not make the tool actuate faster and active

vibration control will notengage.

Tool Tag Ready (Fig. A)

Optional Accessory

Your hammer comes with mounting holes

11

and

fasteners for installing a

Tool Tag. You will need a

T15 bit tip to install the tag. Only use the screws provided.

The

Tool Tag is designed for tracking and locating

professional power tools, equipment, and machines using

the

Tool Connect™ app. For proper installation

and use of the

Tool Tag refer to the

Tool

Tagmanual.

Lock-On Button (Fig. A)

Chipping mode only

The lock-on button

8

offers increased comfort in extended

use applications. To lock the tool on, depress the lock-on

button while the tool is running. The tool will continue to

run after the switch is released. To unlock and turn off the

tool, depress and release theswitch.

NOTE: The lock-on button will not function in drillingmode.

Electronic Speed and Impact Control (Fig. A)

The electronic speed and impact control allows the

use of smaller drill bits without the risk of bit breakage,

hammerdrilling into light and brittle materials without

shattering and optimal tool control for precisechiseling.

To set the speed dial

9

, turn the dial to the desired level.

The higher the number, the greater the speed and impact

energy. Dial settings make the tool extremely flexible and

adaptable for many different appli cations. The required

setting depends on the bit size and hardness of material

beingdrilled.

Overload Clutch

In case of jamming of a drill bit, the drive to the drill spindle

is interrupted by the overload clutch. Due to the resulting

forces, always hold the tool with both hands and take a

firmstance. After the overload, release and depress the

trigger to re-engagedrive.

WARNING: Drill may stall if overloaded causing a

sudden twist. Always expect the stall. Grip the drill

firmly to control the twisting action and avoidinjury.

E-Clutch®

System (Fig. A)

In addition to the integral (mechanical) clutch, the

anti-rotation E-Clutch® system, offers technology capable

of detecting the motion of the tool. This feature senses the

motion of the tool and shuts it down if necessary. The red

indicator LED

10

illuminates when the E-Clutch® System

isengaged.

Loading...

Loading...