8514-296-001 REV A page 59

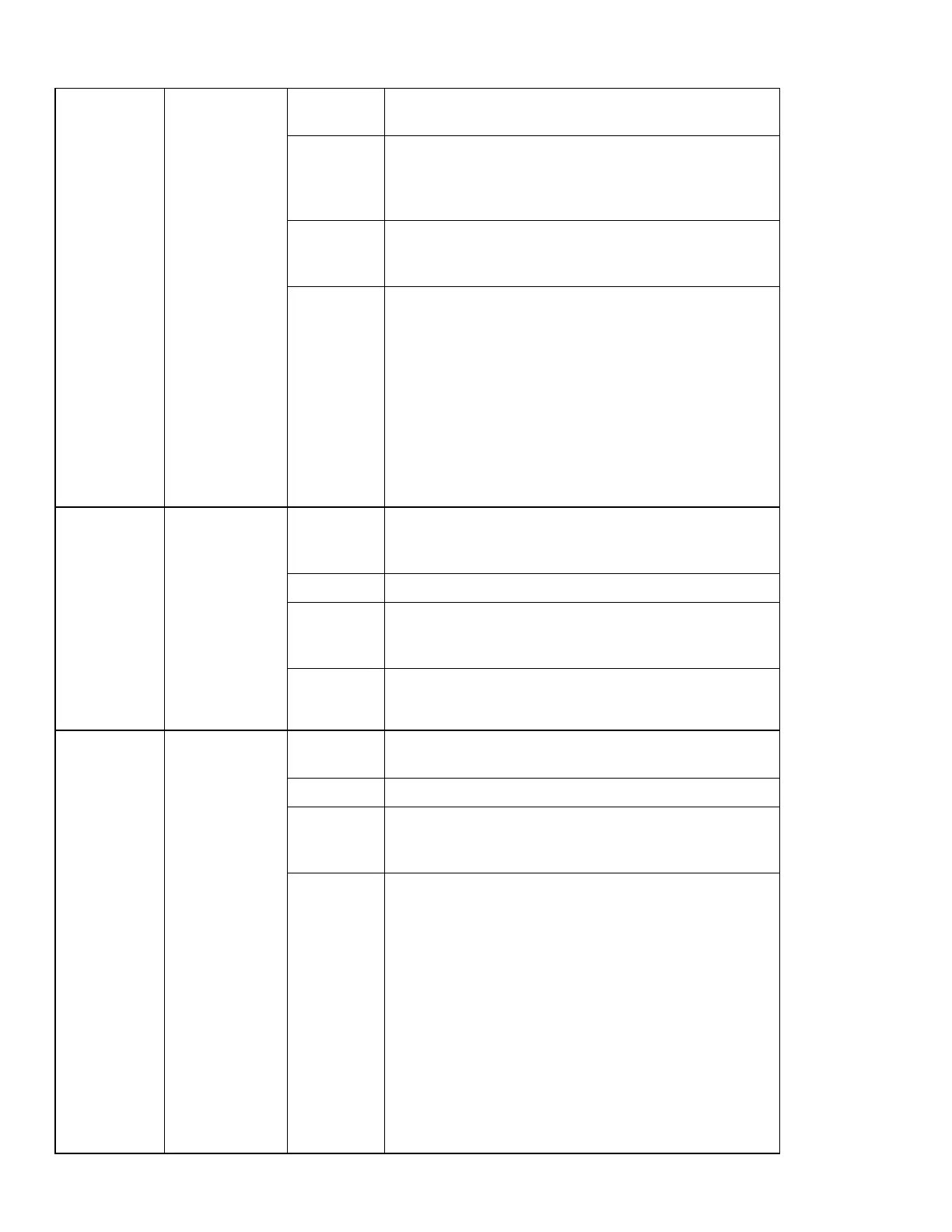

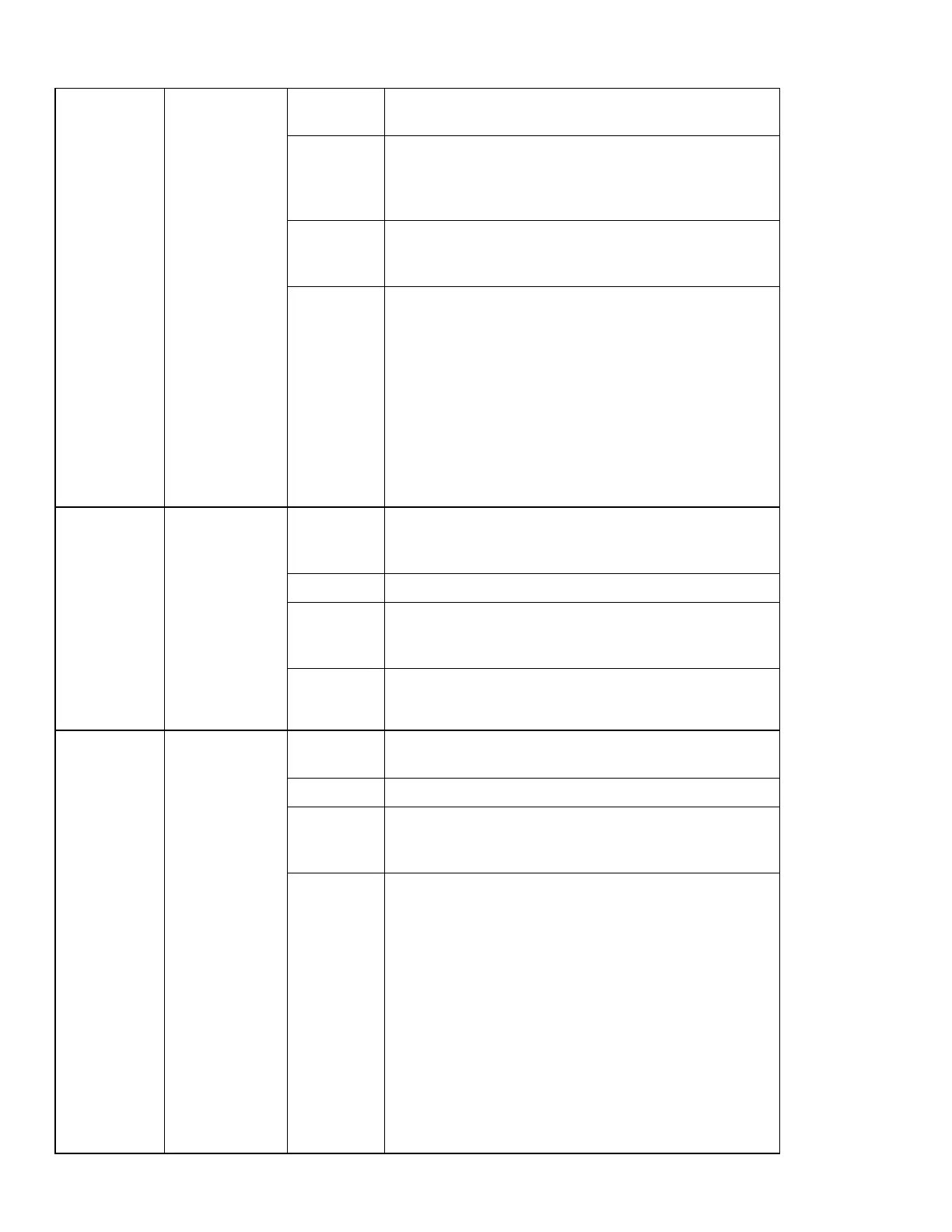

Condition

This error is when the drive size does not match the

washer size.

DRIVE

ERROR1

Washer size/

VFD size

mismatch

Delay

Immediate. (after the size jumper configuration is

read). Washer size/type inputs are read only at power

up, before starting a cycle, once every 24 hours and in

factory test mode

Action

Stop the machine and clear the cycle. Keep the door

locked until the machine has stopped moving and then

unlock the door

Solution

Check VFD fault light before turning off power. If the

controller was installed in a different size machine

before being installed in this machine, a problem can

occur. If someone has been doing repairs on the

washer, check for the correct size drive. It can also be

caused by pressure switch harness. Check to ensure

the correct harness in installed. The control can be

reset by holding program button on controller during

startup (soft reset). Check orange wire at Molex

connector on controller coming from pressure switch

or replace pressure switch harness.

PCB

ERROR2

Controller

Internal Fault Condition

This error is an internal failure of the washer controller

related to inputs being matched between the master

and slave micros

Delay Immediate

Action

Stop the machine and clear the cycle. Keep the door

locked until the machine has stopped moving and then

unlock the door.

Solution

The washer will not restart until the power is removed

and re-applied.

DRIVE OC

VFD Over-

current Fault

Condition This error is an over-current on the VF drive

Delay Delay time is 35 seconds

Action

Stop the machine and clear the cycle. Keep the door

locked until the machine has stopped moving and then

unlock the door.

Solution

Step 1: Check to make sure the washer cylinder turns

freely by hand. If it turns freely, continue to step 2. If

it does not, remove the belt and see if the motor turns

freely by hand. If the motor turns freely, then check

for obstructions in the cylinder or check the bearings.

If the motor does not turn freely, replace the motor.

Step 2: Check the motor wires for a short circuit

between leads. If there are motor leads that have

conductors touching, separate them and insulate

them. If the wires are broken, splice them together or

replace the motor.

Step 3: Check braking resistors to see if they measure

the correct resistance. If a resistor does not measure

the proper value, replace it.

Loading...

Loading...