M

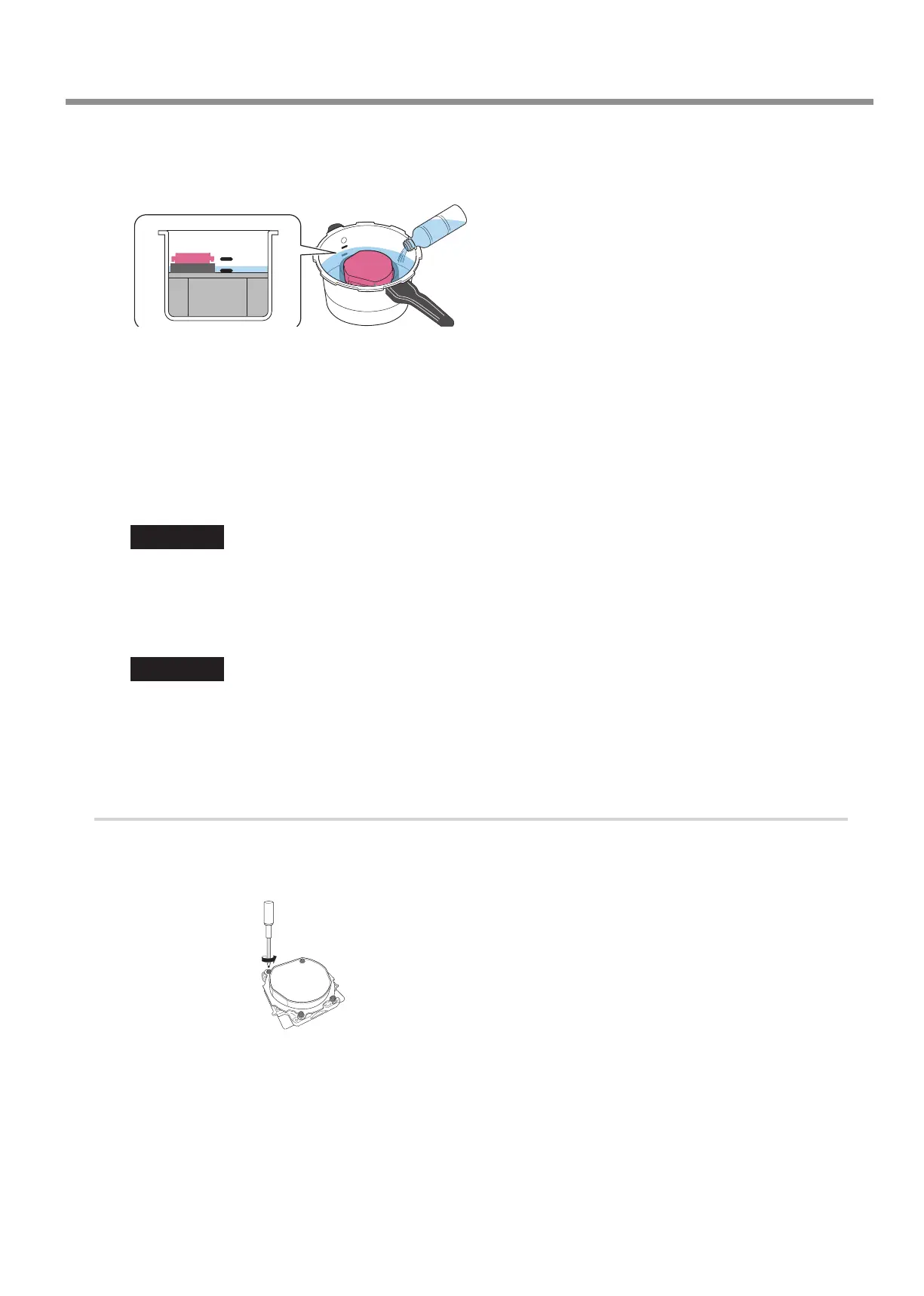

Check the pressure pot's water level and temperature.

• Add water until approximately half the silicone stand is submerged.

• Heat the water until its temperature is between 20°C and 30°C (68°F and 86°F).

N

Apply pressure for approximately 60 minutes.

• After applying pressure, open the lid and check that there is no liquid on the resin surface.

• This time is merely a guideline. Set the time required for the heated polymerizing resin being used to turn rub-

bery.

O

Perform the pre-polymerization.

Gradually increase the water temperature to 65°C (149°F), and then perform pressurized and heated polymerization at 65

°C (149°F) for 90 to 120 minutes.

Important

The pre-polymerization time is merely a guideline. If cracks or air bubbles remain in the heated polymerizing resin being

used, increase this time until there are no cracks or air bubbles.

P

Perform the polymerization.

Perform pressurized and heated polymerization at 80°C (176°F) for 40 minutes.

Important

Heated polymerizing resin polymerizes at high temperatures. Handle it carefully after polymerization to avoid burns.

Q

Remove the FX from the silicone stand, and then leave the FX at room temperature for approximately 30 minutes.

R

Cool the FX for approximately 15 minutes with cold water.

3.

Mill the denture resin.

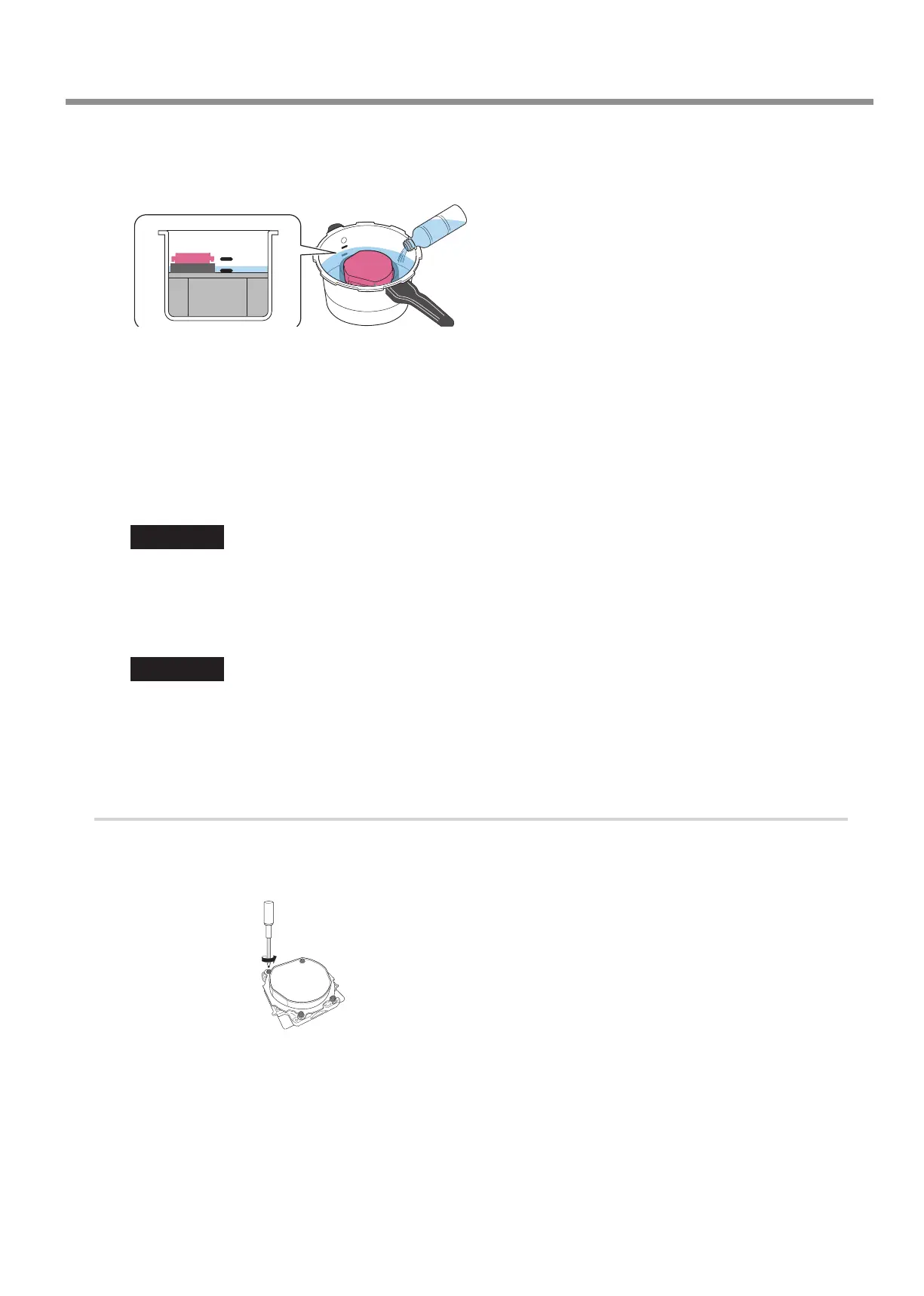

A

Remove the adapter cap.

Use a torque screwdriver to loosen the adapter's cap screws by turning them approximately four times each, and then re-

move the adapter cap.

Usage Method

15

Loading...

Loading...