G

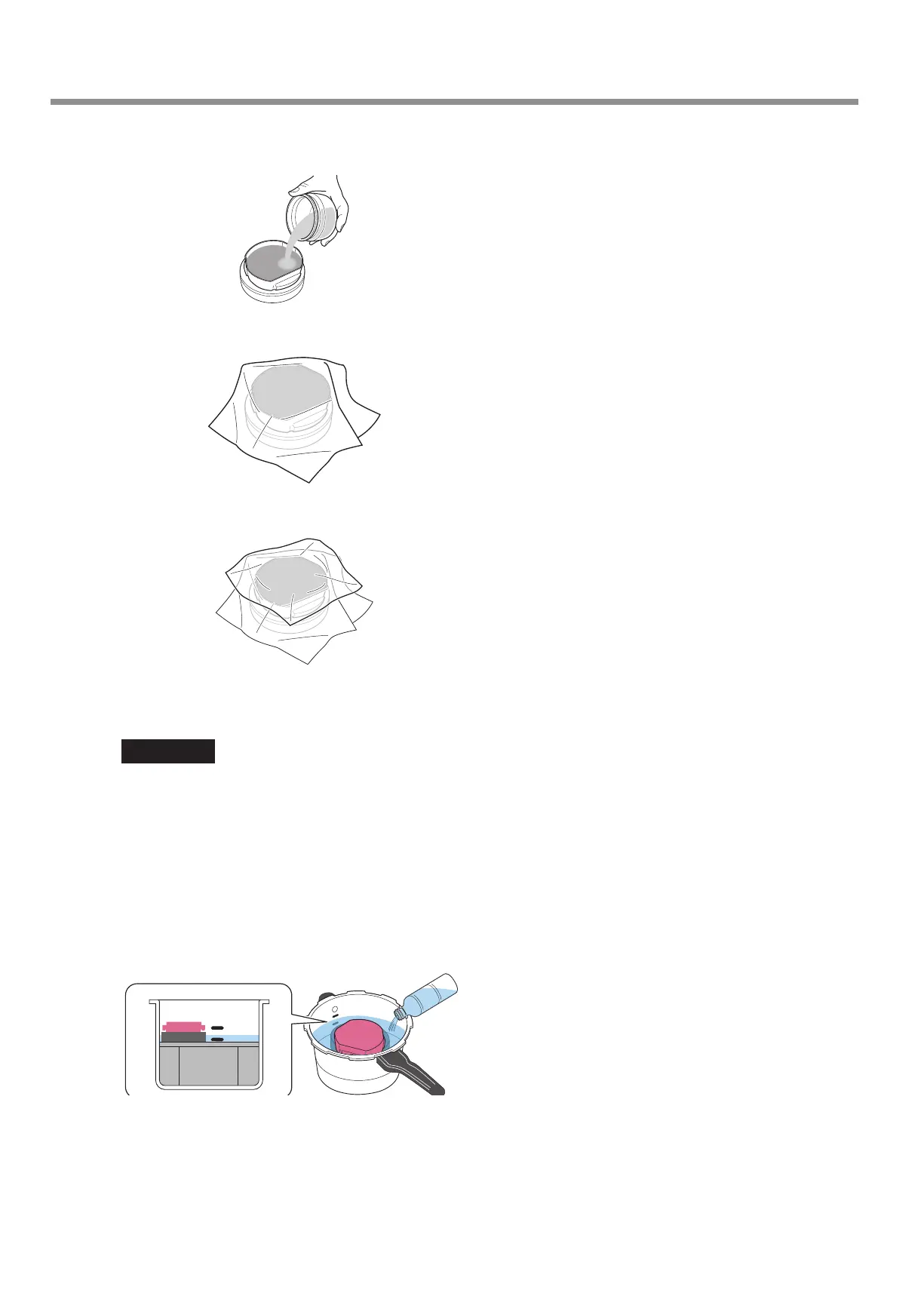

Pour the mixture into the FX.

Flatten the surface of the mixture with a spatula.

H

Cover the mixture with a piece of tissue paper.

I

Place a polyethylene sheet on the tissue paper.

J

Lightly press down on the polyethylene sheet and the tissue paper to absorb the liquid layer from the surface of

the mixture.

Important

A liquid layer remaining on the surface may cause air bubbles to form there after polymerization.

K

Remove the polyethylene sheet and the tissue paper.

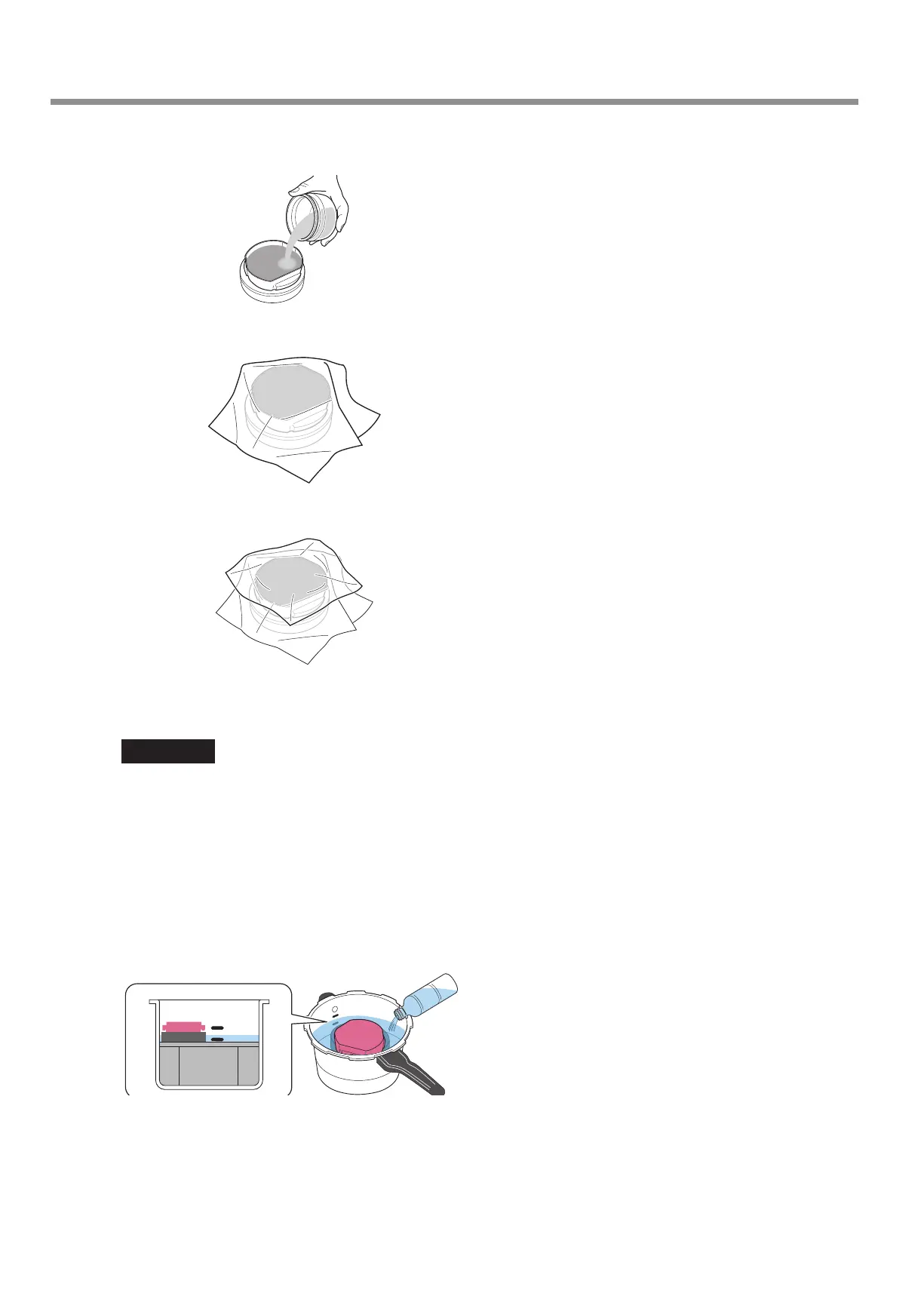

L

Place the silicone stand and the FX in the pressure pot.

M

Check the pressure pot's water level and temperature.

• Add water until approximately half the silicone stand is submerged.

• Heat the water until its temperature is between 20°C and 30°C (68°F and 86°F).

N

Apply pressure for approximately 60 minutes.

• After applying pressure, open the lid and check that there is no liquid on the resin surface.

• This time is merely a guideline. Set the time required for the heated polymerizing resin being used to turn rub-

bery.

Usage Method

20

Loading...

Loading...