7. PREPARING FOR PROFILING

Before use, make sure that the characteristics of the sheet used correspond to the profiling capacity of

the machine (see "GENERAL CHARACTERISTICS - DETAILED CHARACTERISTICS" chapter 3).

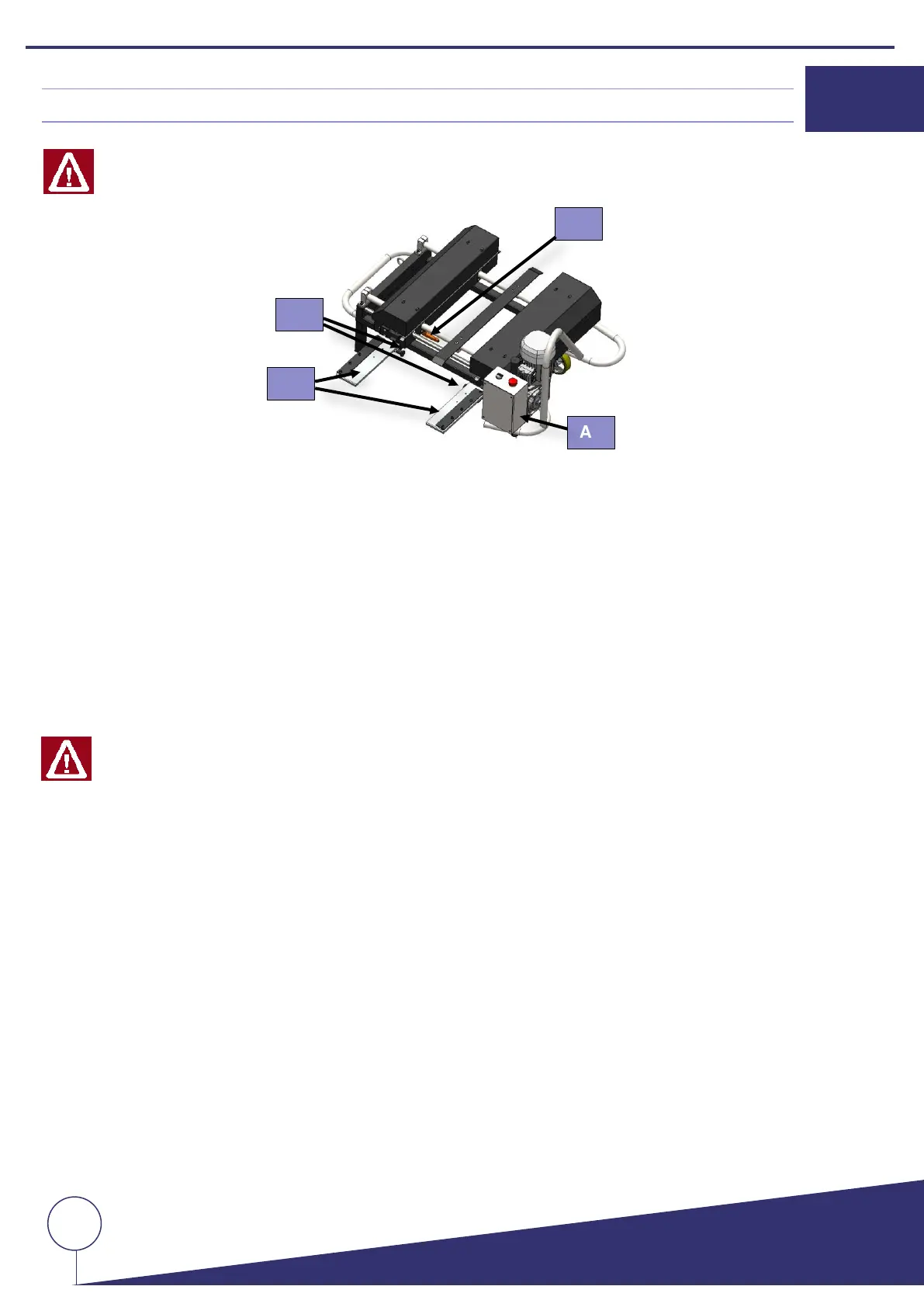

Lower the input guides, using the A4 locking bolts.

Unlock the sliding bank using the A3 handle.

Open up the profiling banks

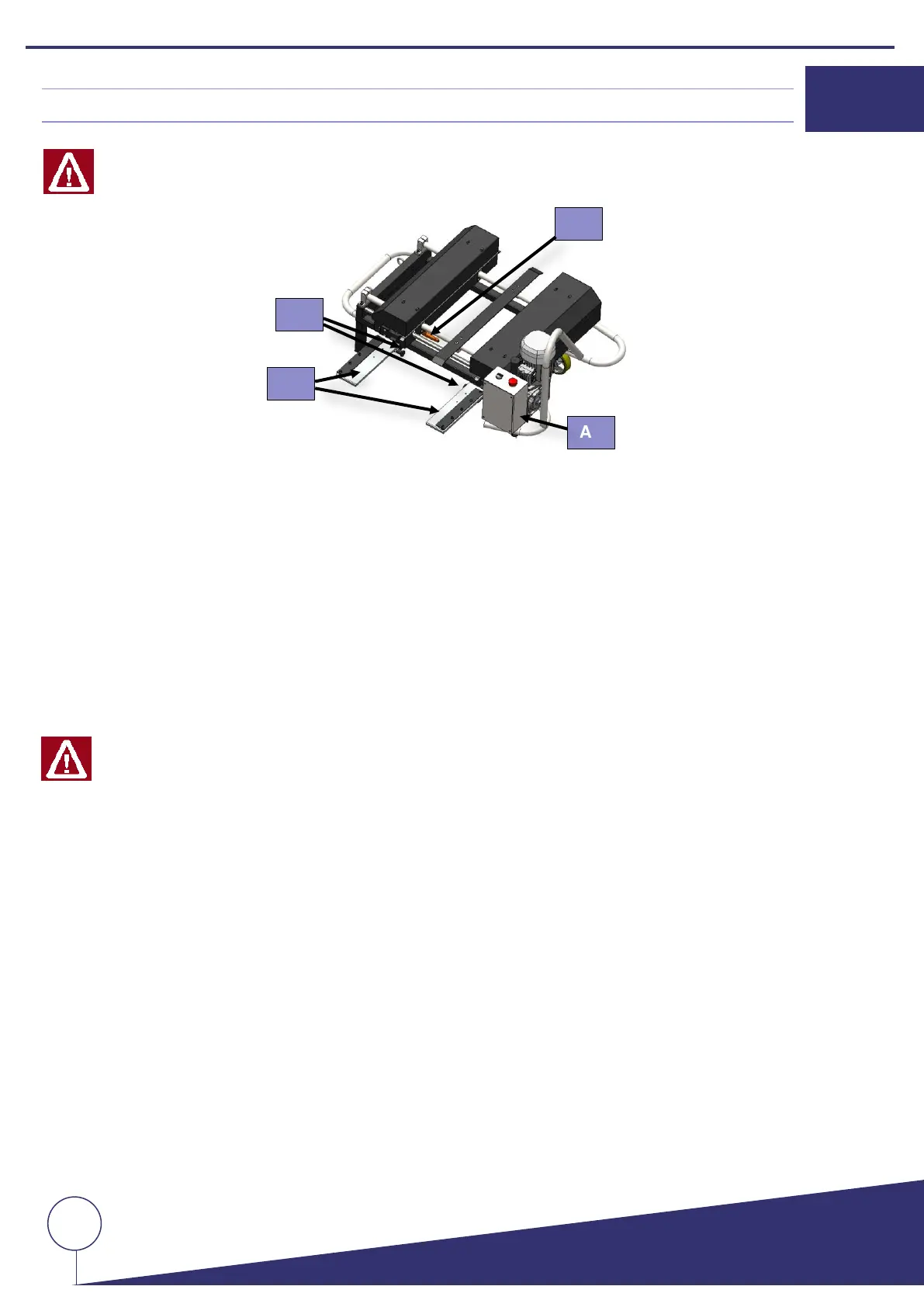

Manually move the metal strip forward inside the machine.

Adjust the width of the inlet guides to the width of the sheet metal strip.

Use the clamping handle A3 to lock the train in position

The material must be able to slide between the guides without any lateral movement.

Too tightly adjusted → Sheet jams

Adjusted with too much give → Imprecise profiling

Be sure to tighten the A3 handle sufficiently to avoid any inadvertent movement of the bank during the

roll-forming.

Wear appropriate, lightweight clothing that you are comfortable in.

Put on your safety shoes to avoid accidents due to anything falling to the floor. Put on gloves to avoid cuts.

Loading...

Loading...