Dingo K9-3 Operation & Maintenance Manual

17

7 Check uid level in hydraulic tank and add oil

to raise level to 75mm below the top of the tank.

DO NOT OVER FILL.

Changing the Hydraulic Fluid

Change the hydraulic uid after every 500 oper-

ating hours.

IMPORTANT: Do not substitute with auto-

motive oil or severe hydraulic damage may

result.

1 Position the Dingo on a level surface, lower

the arms and turn the ignition key to OFF to stop

the engine. Remove the key.

2 Place large drain pan under the machine that

can hold at least 70 litres.

3 Remove the drain plug from the bottom of the

hydraulic tank and allow the uid to completely

drain out.

4 Remove the tank top and wipe out the inside

of the tank and wash out with petrol. If anything

unusual is found, consult your Dingo service

centre or a hydraulic expert. The tank needs to

be spotlessly clean to preserve the hydraulic

system.

5 Install the drain plug.

6 Fill the hydraulic tank with approximately 57

litres of HVI 68 hydraulic oil.

Note: Dispose of used oil in accordance with

local authority regulations. Only use HVI 68

oil. Use of other oil grades can cause loss of

hydraulic power, or damage to machine.

Check Hydraulic Lines

After every 100 operating hours, check hydraulic

lines and hoses for leaks, loose ttings, kinked

lines, loose mounting supports, wear, weather

and chemical deterioration. Replace all mov-

ing hydraulic hoses every 1500 or two years,

whichever comes rst. Make necessary repairs

before operating.

WARNING! Hydraulic oil escaping under

pressure can penetrate the skin and cause

injury.

Keep hands and body away from pin hole leaks

or nozzles that eject high pressure hydraulic

uid. A small leak can be dangerous. To nd

hydraulic leaks use cardboard or paper.

If uid is accidentally injected into the skin a

doctor familiar with this type of injury must

surgically remove it within a few hours.

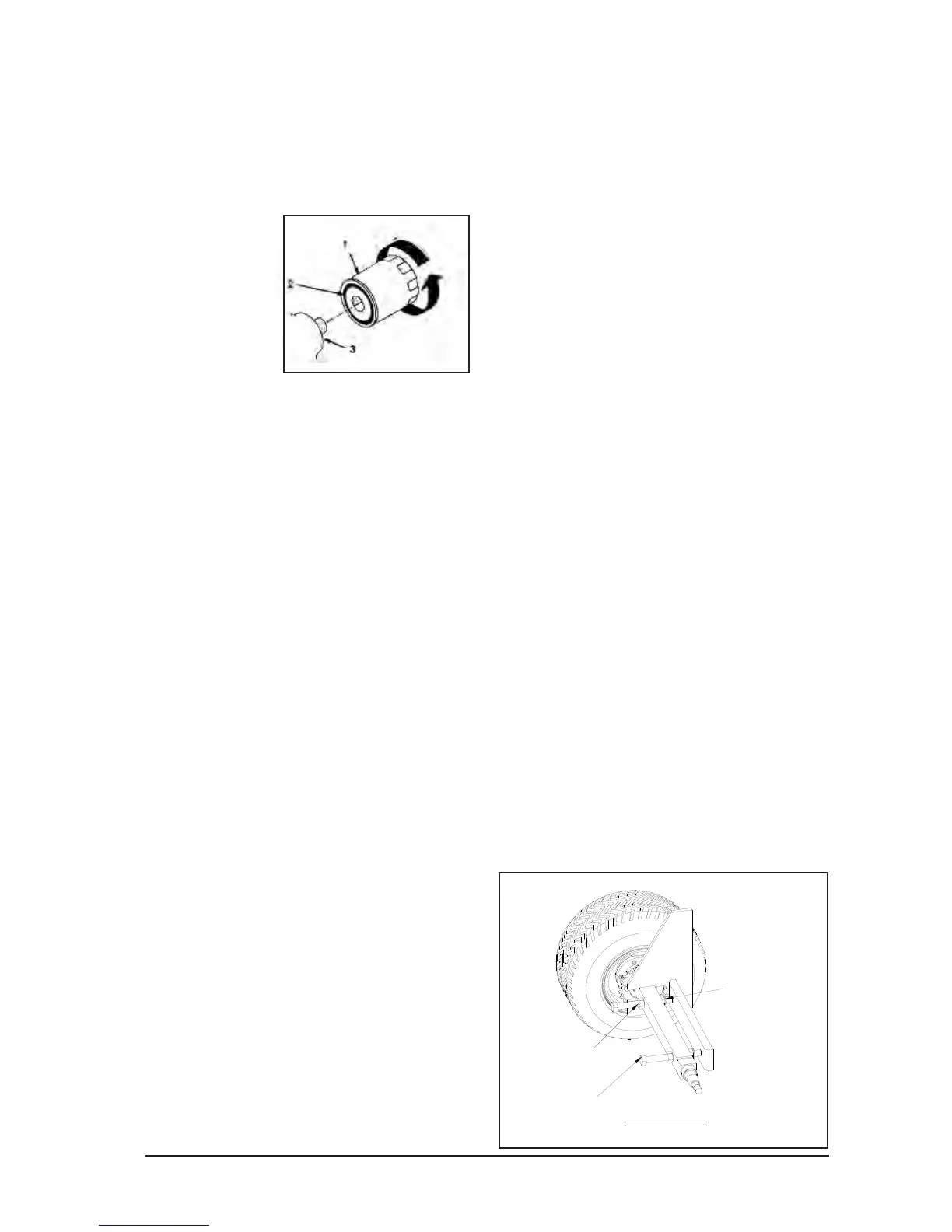

Adjusting Drive Chains

When properly adjusted, drive chains should

have approximately 50 - 75mm of slack. On

newer models this can be checked by using the

Tension Gauge on the Chain Guard. The chain

tension adjustment bolts are on the front axle.

To check the chain tension:

1 Remove the chain guard (Unless chain guards

have Tension Gauge cut into them)

2 Tilt the bucket so that the front wheels lift off

the ground

3 In that position, check the chain by pressing

down on the top chain. There should be 50

- 75mm between the top of the chain and the

bottom of the mudguard. If tted with the Ten-

sion Gauge in the chain Guard, pull down on

the chain. The bottom of the chain should sit

between the two notches in the slot.

Chains should be run dry for maximum chain

life - do not use oil or chain lubricant.

Loading...

Loading...