Dingo K9-3 Operation & Maintenance Manual

18

Dingo K9-3 Operation & Maintenance Manual

19

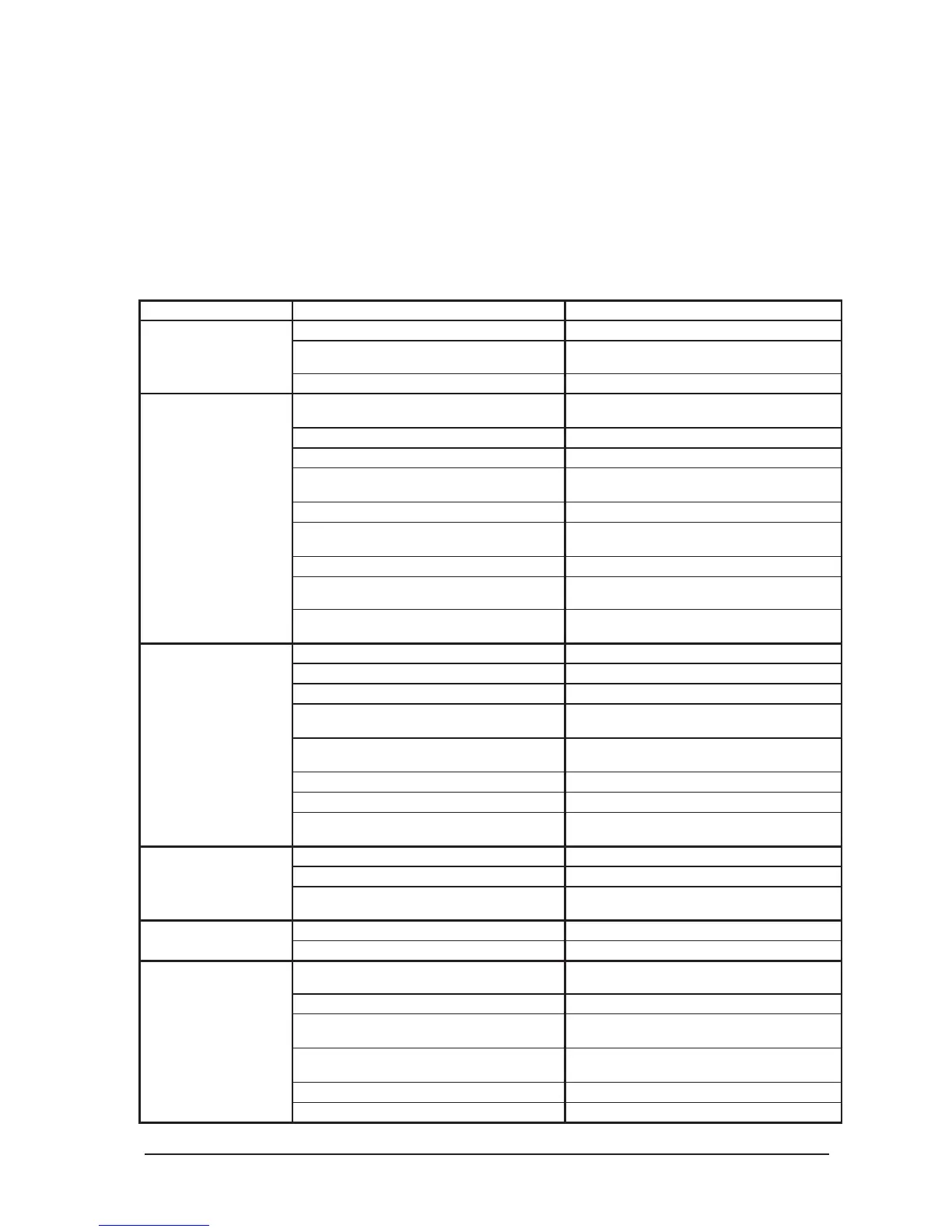

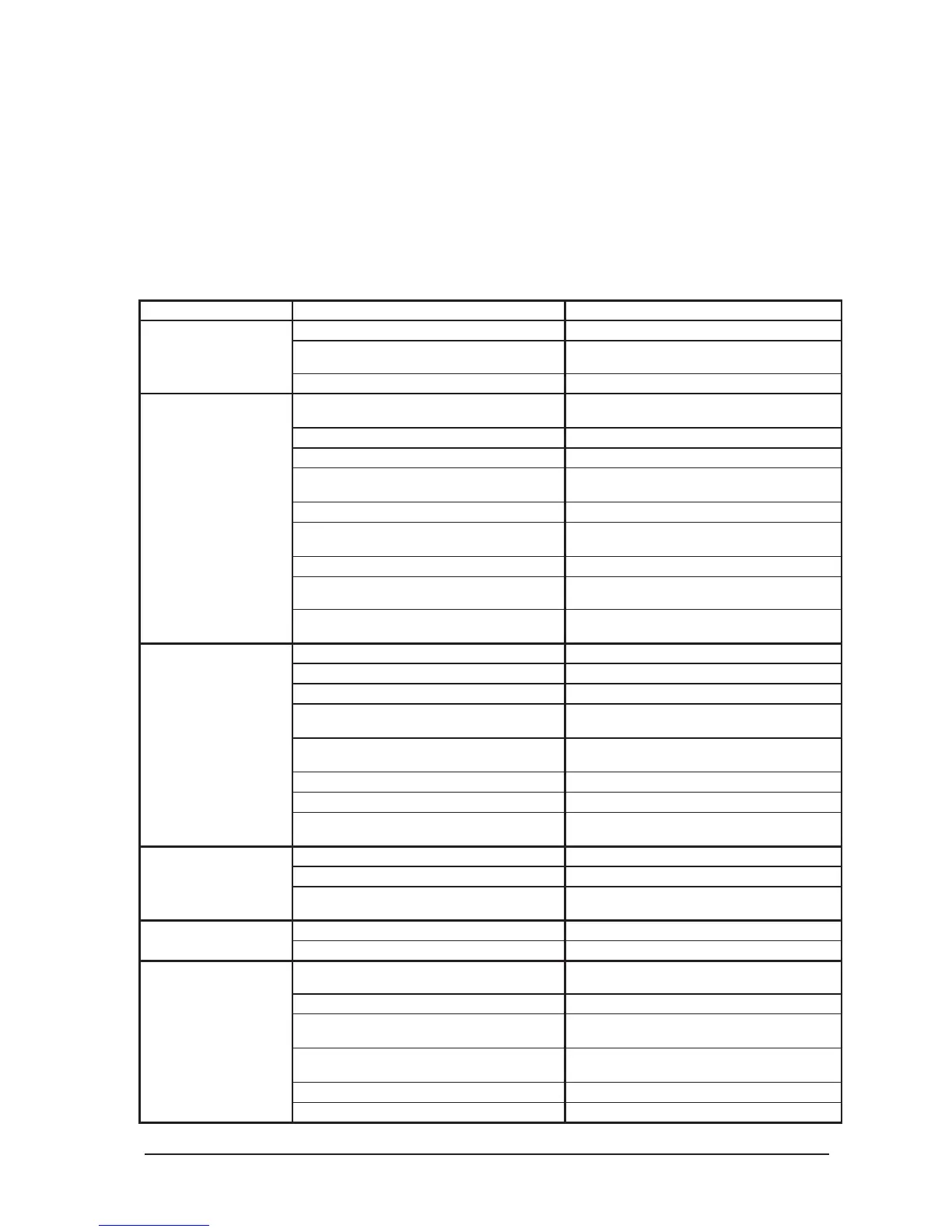

Troubleshooting

Problem Possible Causes Corrective Action

Starter does not crank

.

.

.

1. Battery is dead 1. Charge battery

2. Electrical connections are corroded or loose 2. Check electrical connections for good contact

3. Relay switch is defective 3. Contact authorised service dealer

Engine will not start, hard

to start or fails to keep

running .

.

.

.

.

.

.

.

. .

.

.

1. Auxiliary hydraulics lever is not in neutral posi-

tion

1. Move the lever to neutral position

.

2. Fuel tank is empty 2. Fill fuel tank with appropriate fuel

3. Choke is not on (petrol models) 3. Move choke to ON

4. Spark plug wires are loose or disconnected.

(petrol models)

4. Install wire on spark plug

.

5. Air cleaner is dirty 5. Clean or replace air cleaner element

6. Spark plugs are pitted, fouled, or gap is incor-

rect (petrol Models)

6. Install new, correctly gapped spark plugs

.

7. Dirt in fuel filter 7. Replace fuel filter

8. Dirt, water or stale fuel in the fuel tank 8. Drain fuel tank and filter and replace fuel

9. Dirt, water or stale fuel in the fuel system 9. Contact authorised dealer

Engine looses power

. .

.

.

.

.

.

.

.

.

.

1. Engine load is excessive 1. Reduce ground speed

2. Air cleaner is dirty 2. Clean or replace air cleaner element

3. Oil level in crankcase is low 3. Add oil to crankcase

4. Cooling fins and air passages under engine

blower housing are blocked

4. Remove obstruction from cooling fins and air

passages

5. Spark plugs are pitted, fowled, or gap is incor-

rect (petrol Models)

5. Install new, correctly gapped spark plugs

.

6. Dirt in fuel filter 6. Replace fuel filter

7. Dirt, water or stale fuel in the fuel tank 7. Drain fuel tank and filter and replace fuel

8. Dirt, water or stale fuel in the fuel system 8. Contact authorised dealer

Engine overheats

. .

.

1. Engine load is excessive 1. Reduce ground speed

2. Oil level in crankcase is low 2. Add oil to crankcase

3. Cooling fins and air passages under engine

blower housing are blocked

3. Remove obstruction from cooling fins and air

passages

Abnormal vibration

.

1. Engine mounting bolts are loose 1. Tighten engine mounting bolts

2. Engine mounts are broken 2. Replace engine mounts

Machine does not

drive

.

.

.

.

.

.

.

1. Flow divider valve is in 9 O’clock position 1. Move the lever to 12 o’clock position

2. Hydraulic fluid level low 2. Add hydraulic fluid to reservoir

3. Traction pump drive coupler is loose or broken

3. Contact authorised service dealer

.

4. Pump and/or wheel motor is defective or dam-

aged

4. Contact authorised service dealer

.

5. Control valve is defective or damaged 5. Contact authorised service dealer

6. Relief valve is defective or damaged 6. Contact authorised service dealer

Cover the machine to protect it and keep it

clean.

Loading...

Loading...