1820 - MAINTENANCE 73

TRENCHING ATTACHMENT

1820 - MAINTENANCE 73

TRENCHING ATTACHMENT

TRENCHING ATTACHMENT

Chain Wear

Replace worn or broken chains. If sidebars are bending or getting

loose on chain pins, chain spacers should be used to join

sidebars.

Digging Chain

Visually check digging chains for wear on rollers and sidebars.

Check pins and bushing wear by measuring distance between

chain pins and comparing it to new chain.

Replace sprockets when new chain is installed.

To remove digging chain:

1. Start unit, following directions in OPERATION section.

2. Turn digging chain until connector pin is on top of boom.

3. Lower boom to ground.

4. Stop engine.

5. Secure chain.

Sprocket booms - Lock rear idler sprocket.

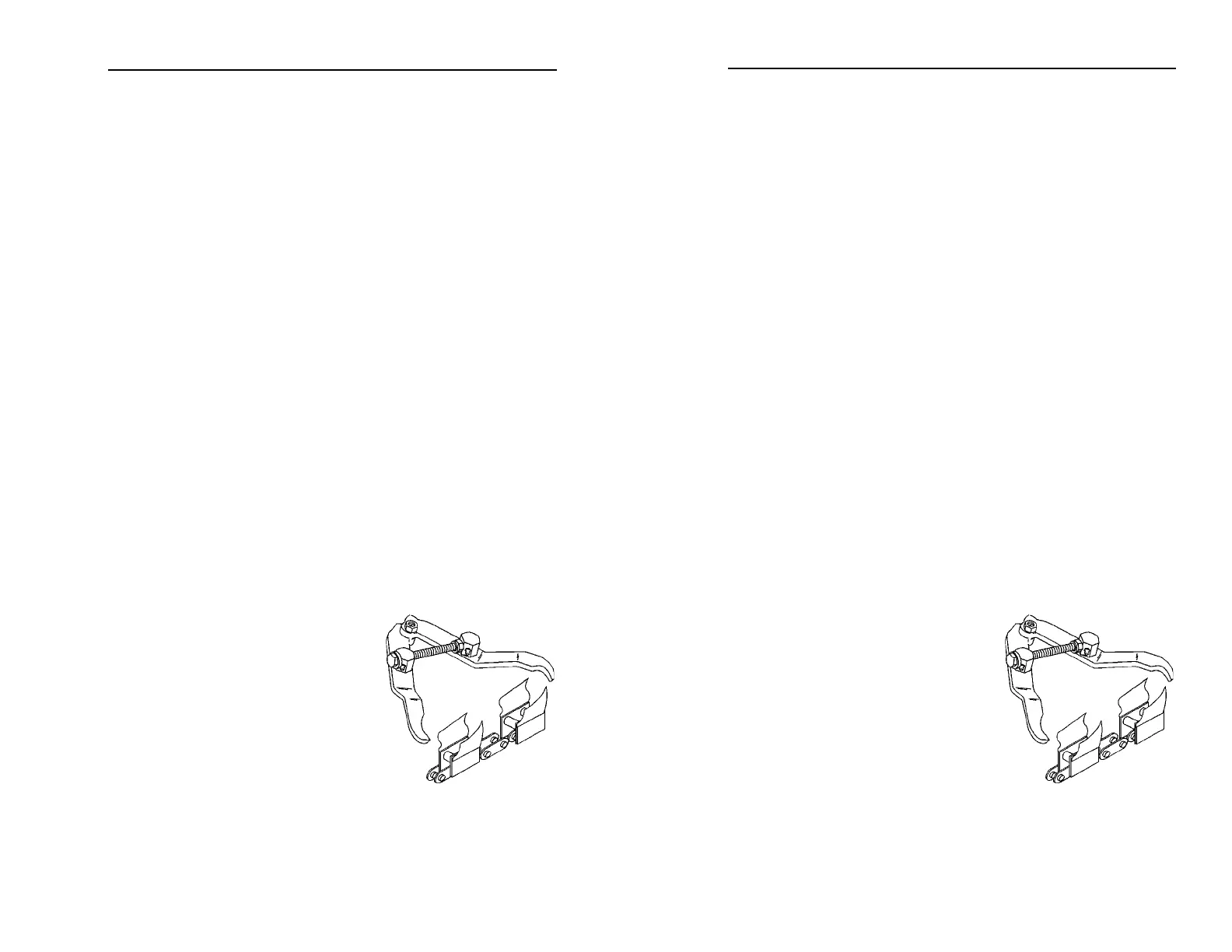

Roller booms - Clamp links on

either side of connector pin with

chain jaws. Squeeze jaws to

reduce pressure on connector pin.

om1752

TRENCHING ATTACHMENT

Chain Wear

Replace worn or broken chains. If sidebars are bending or getting

loose on chain pins, chain spacers should be used to join

sidebars.

Digging Chain

Visually check digging chains for wear on rollers and sidebars.

Check pins and bushing wear by measuring distance between

chain pins and comparing it to new chain.

Replace sprockets when new chain is installed.

To remove digging chain:

1. Start unit, following directions in OPERATION section.

2. Turn digging chain until connector pin is on top of boom.

3. Lower boom to ground.

4. Stop engine.

5. Secure chain.

Sprocket booms - Lock rear idler sprocket.

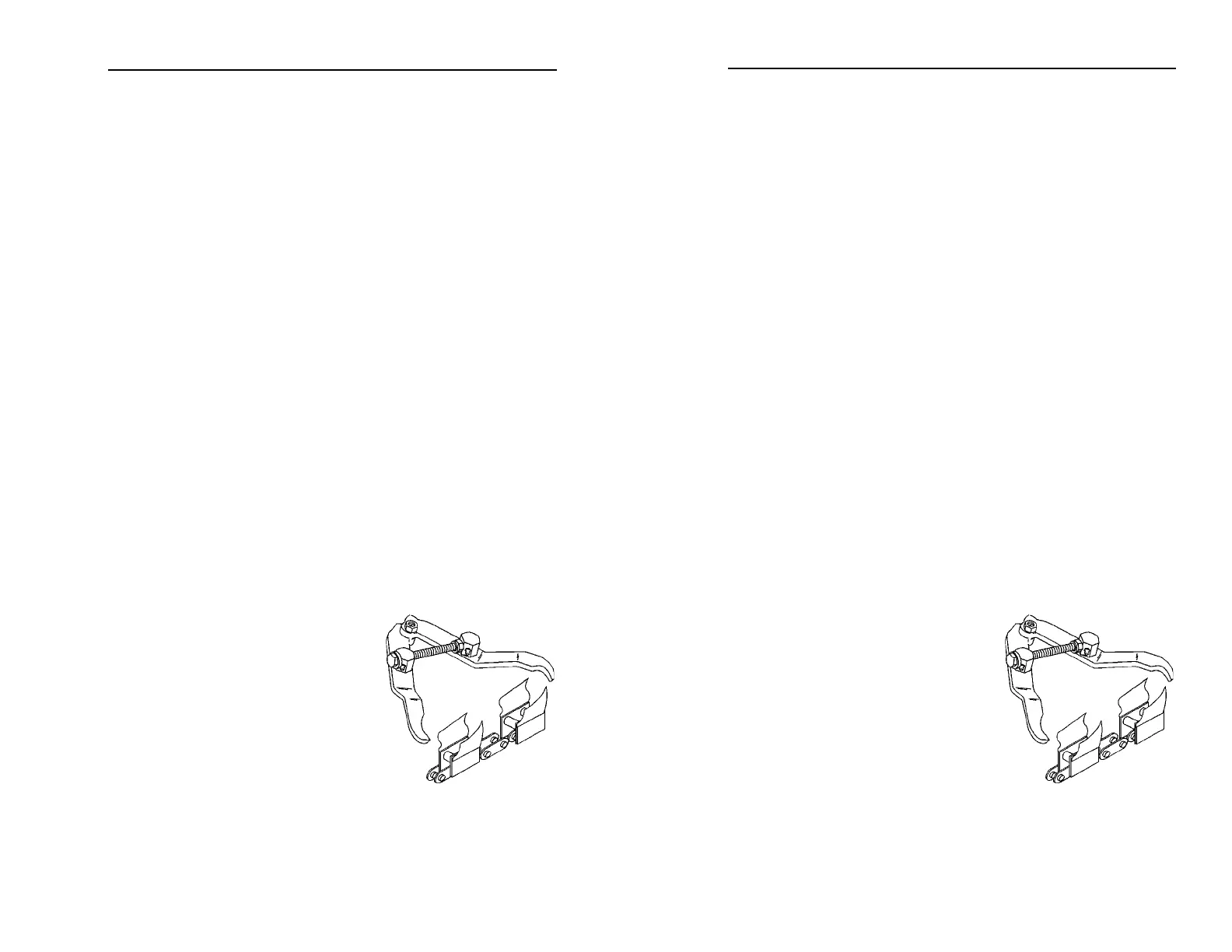

Roller booms - Clamp links on

either side of connector pin with

chain jaws. Squeeze jaws to

reduce pressure on connector pin.

om1752

Loading...

Loading...