1. TECHNICAL DATA

ARC B ARC 1BH ARC BH

Power supply 230 V~ / 50 Hz 24 V= 24 V=

Absorption 1,2 A 12 A 3 A

Torque 300 Nm 300 Nm 150 Nm

Run time 22 s/90° 15÷30 S/90° 15÷18 s/90°

Service class 3 - FREQUENT 4 - HEAVY DUTY 4 - HEAVY DUTY

Min. number of consecutive cycles 20 >50 >50

Intermittence S2 = 15 min, S3 = 25% S2 = 30 min, S3 = 50% S2 = 30 min, S3 = 50%

Temperature -20° C / +55° C -20° C / +55° C -20° C / +55° C

Degree of protection. IP54 IP54 IP54

Control panel E2 / Logic A21-A22 Logic C22 D2H / Logic C22-C22S

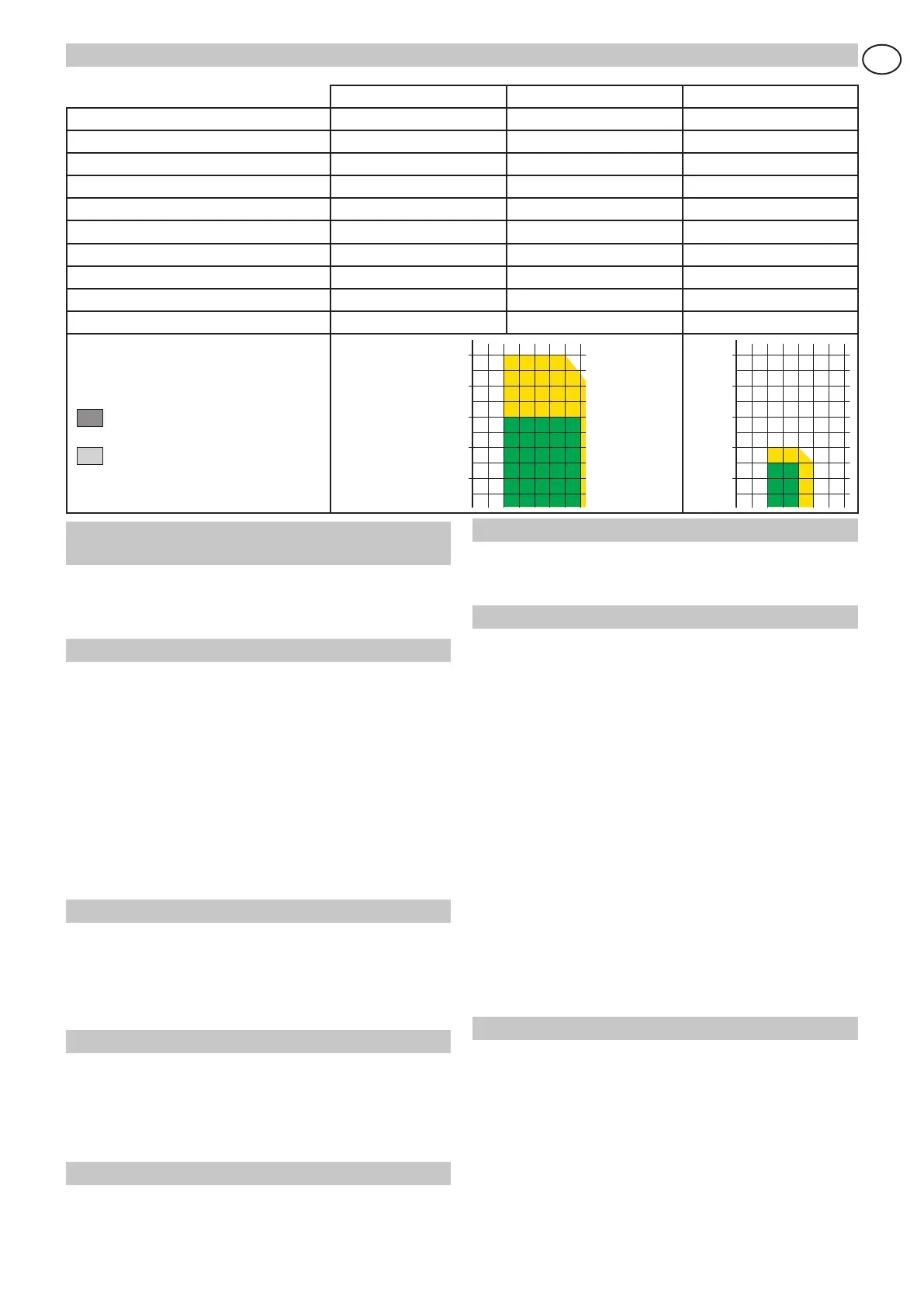

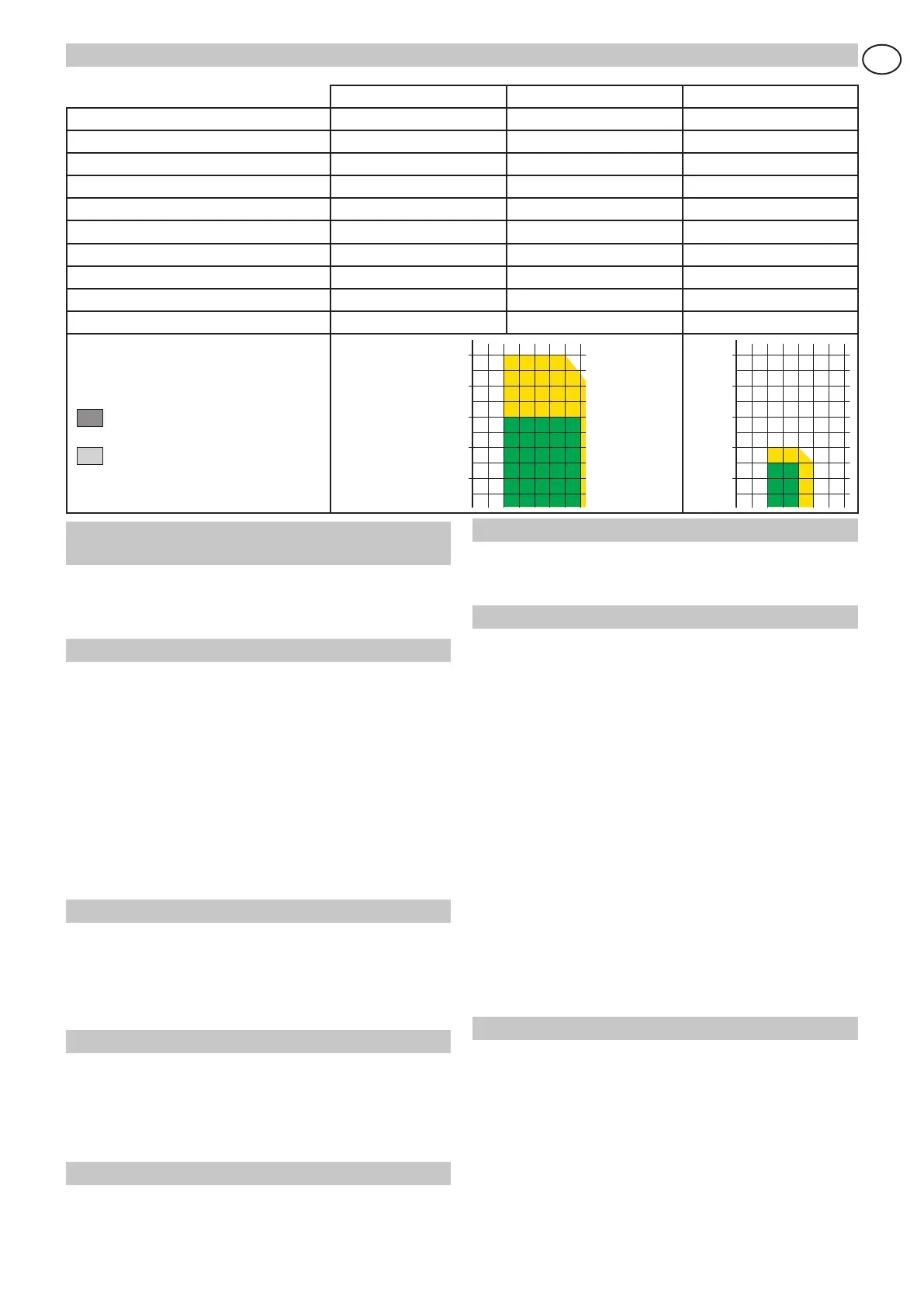

Application:

mm = door wing width

kg = door wing weight

Recommended dimensions

Limit dimensions

500 kg

400 kg

300 kg

200 kg

100 kg

m12345

500 kg

400 kg

300 kg

200 kg

100 kg

m12345

2. REFERENCE TO ILLUSTRATION and AC-

CESSORIES

The given operating and performance features can only be

guaranteed with the use of DITEC accessories and safety

devices.

2.1 Standardinstallationreferences(g.1)

[1] Radio

[2] Flashing light

[3] Key selector

[4] Connect power supply to a type-approved omnipolar-

switch with a contact opening gap of no less that

3 mm (not supplied by us) protected against accidental

and unauthorized activation. Connection to supply mains

must be carried out in an independent raceway separate

from control connections and safety device connections.

[5] Control panel

[6] Arc B geared motor

[7] Photocells

2.2 Geared motor references

[8] Gate attachment bracket

[9] Housing

[10] Attachment plate

[11] Drilling templates for release key

[12] Release shaft

2.3 Accessories

ArcFB(*) Adjustable stop

ArcPL(*) Plate for front attachment of geared motor

Box FC1 Limit switch

(*) Two TCEI M8x130 screws, don’t supply by us, are necessary in

order to use the ArcFB and ArcPL accessories at the same time.

3. INSTALLATION

Unless otherwise specied, all measurements are expressed

in millimetres.

3.1 Preliminary checks

Check that the structure is sufciently sturdy and that the hinge

pivots are properly lubricated. Provide an opening and closing

stop.

3.2 Geared motor installation

- Remove the geared motor from its package. Attention:

Cover [9] is not secured.

- Disassemble the reduction gear from the fixing plate [10].

- Attach plate to gate column according to measurements

specified in figures 6 and 7, depending on type of installation.

- Assemble the geared motor on the fixing plate following

fig. 8 for the fitting onto the left pier, inside view, and fig.

9 for fitting onto the right pier, inside view.

- Release the geared motor (see operating instruction).

- Attach articulated arms and gate attachment bracket as

shown in figures 10 and 11 and according to measure-

ments specified in figures 6 and 7.

Attention: bring the leaf to the stop line, align the arms

by means of holes [D] as shown in the detail in fig. 10.

The articulations on the arms should be lubricated and

the screws tightened in such a way as not to block arm

movement.

- Drill the cover Ø 14 near release shaft [12] (there are two

drilling templates [11] in side the cover) and insert the

rubber plug (supplied). Attach the cover to the geared

motor.

4. ELECTRICAL CONNECTION

- ARC B geared motor electrical wiring and starting are

shown in fig. 12 and in the installation manual of Control

Panel E2, Logic A21 and LogicA22. To reverse the direc-

tion of rotation, exchange the motor phases (U with V

and/or X with Y).

- ARC 1BH geared motor electrical wiring and starting

are shown in fig. 15 (1 wing) or in fig. 16 (2 wings) and

in the installation manual of Control Panel LogicC22. To

reverse the direction of rotation, exchange the motor

phases (36 with 34 and/or 33 with 31).

Loading...

Loading...