1

INTRODUCTION

The Dometic VARC (Variable Chiller) controls is a microcontroller-based unit designed to control multiple chillers. This design

allows the user flexibility in the application and improved controls and protection. The VARC Chiller uses a PID loop control to

manage the capacity of the chiller in single or multistage application. This completely variable capacity chiller uses a VFD to

modulate the speed of the compressor to achieve the desired chilled water setpoint. This allows the compressor to be ran at a

minimum speed of 30Hz to a maximum of 240 Hz.

The VARC48 uses a precision PID (proportional integral derivative) loop control algorithm that modulates the compressor speed

and balances chiller output with required load. This smooth operation eliminates large swings in current on the generator. The

VARC48 also uses the advanced technology of an Electronic Expansion Valve (EEV). This provides more precise control of

superheat across a broad range of conditions with no erratic swings as the valve reacts to temperature and pressure changes (no

“hunting”). Using an advanced algorithm, superior superheat control is maintained over extreme operating conditions.

This application supports the following:

o Selection and sequencing of up to four chillers

o Selection and sequencing of one chilled water pump and one sea water pump

o Selection and sequencing of up to 4 EH heaters

o Sequencing of devices for runtime equalization

o Alarms and interlocks

o Load Shedding

o Troubleshooting help

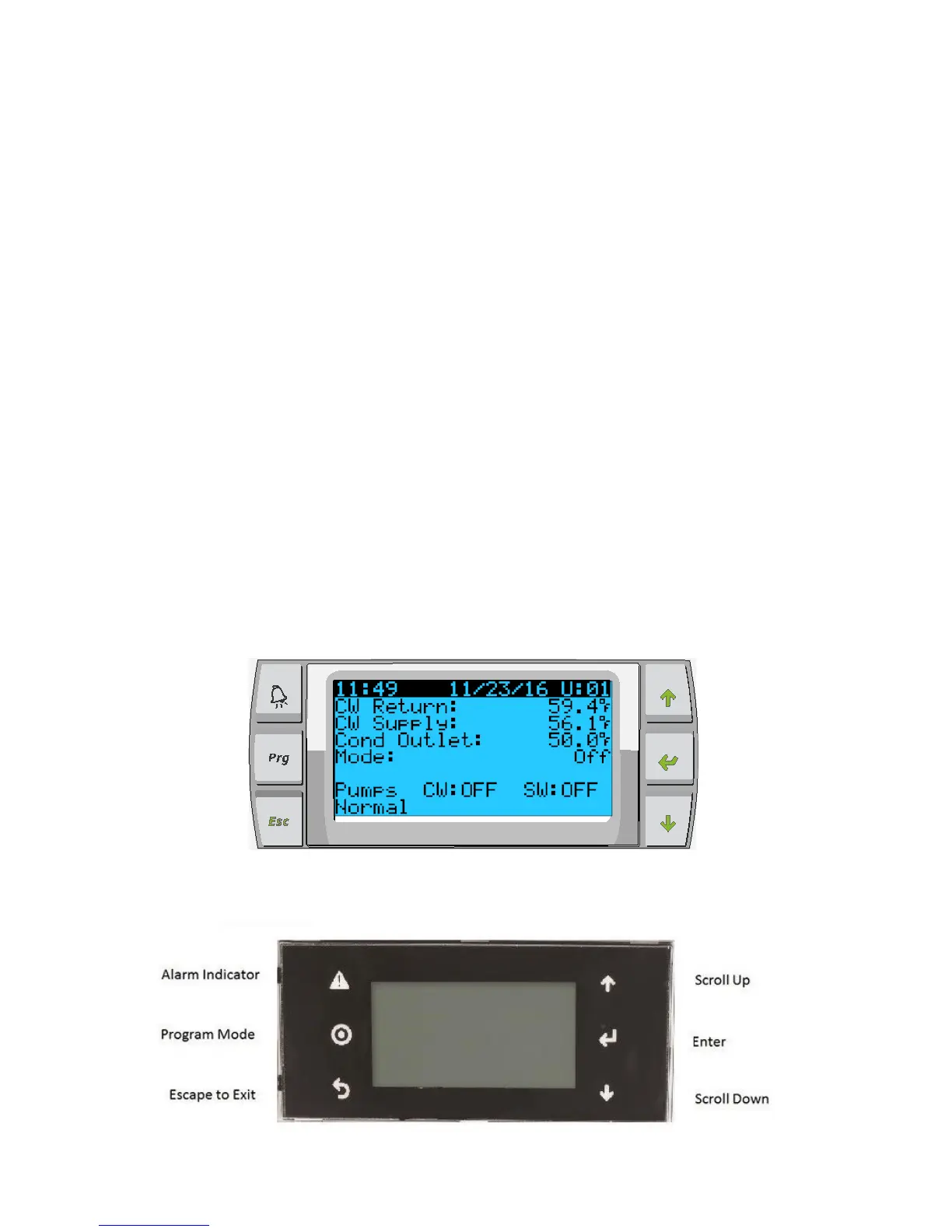

The three main interfaces supported will be the LCD display, referred to as the PGD1 or PLDPRO display, and the HMI

touchscreen.

Figure

1:

PGD1 Button

Desc

r

i

ptio

n

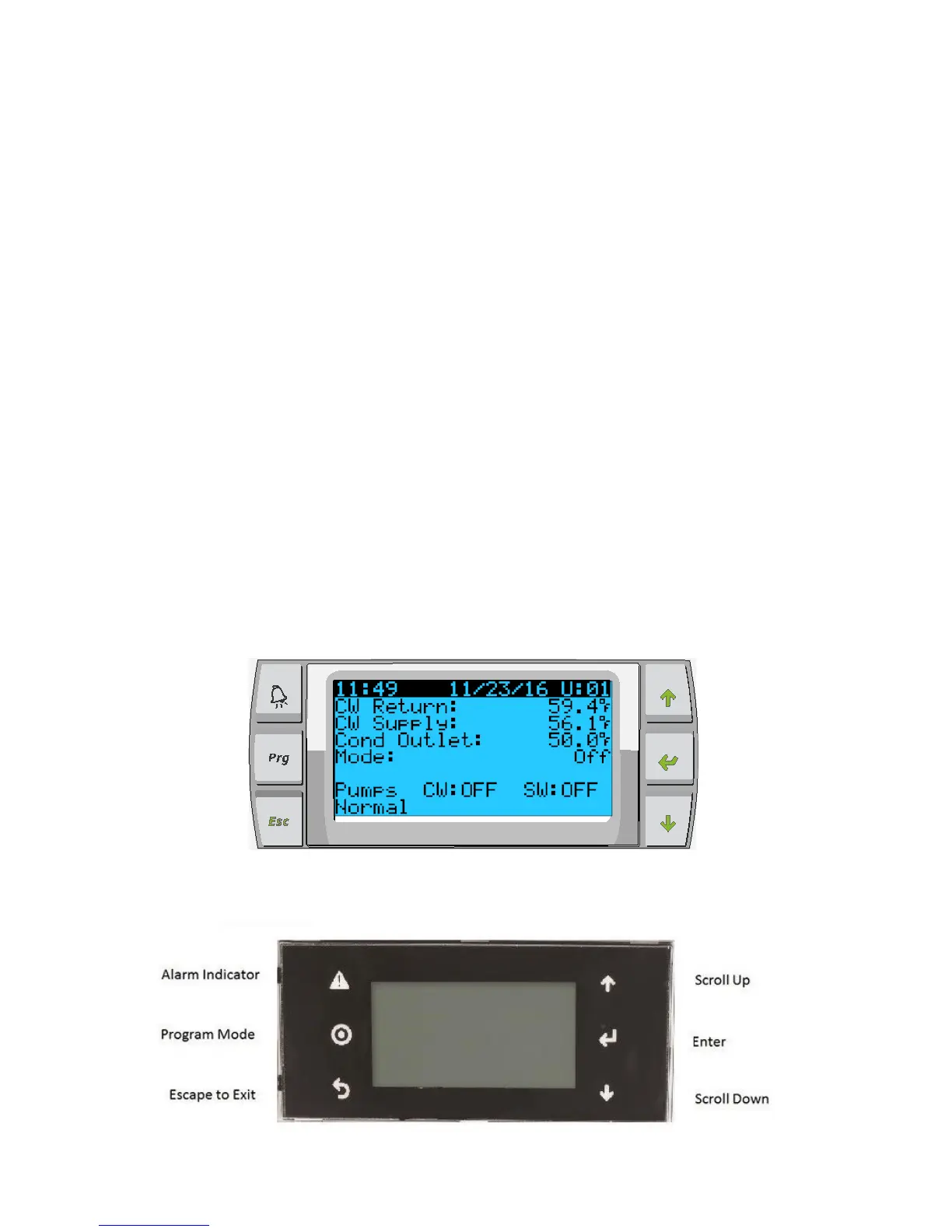

Figure 2: PLDPRO Button Description

Loading...

Loading...