Power Train Disassembly & Assembly

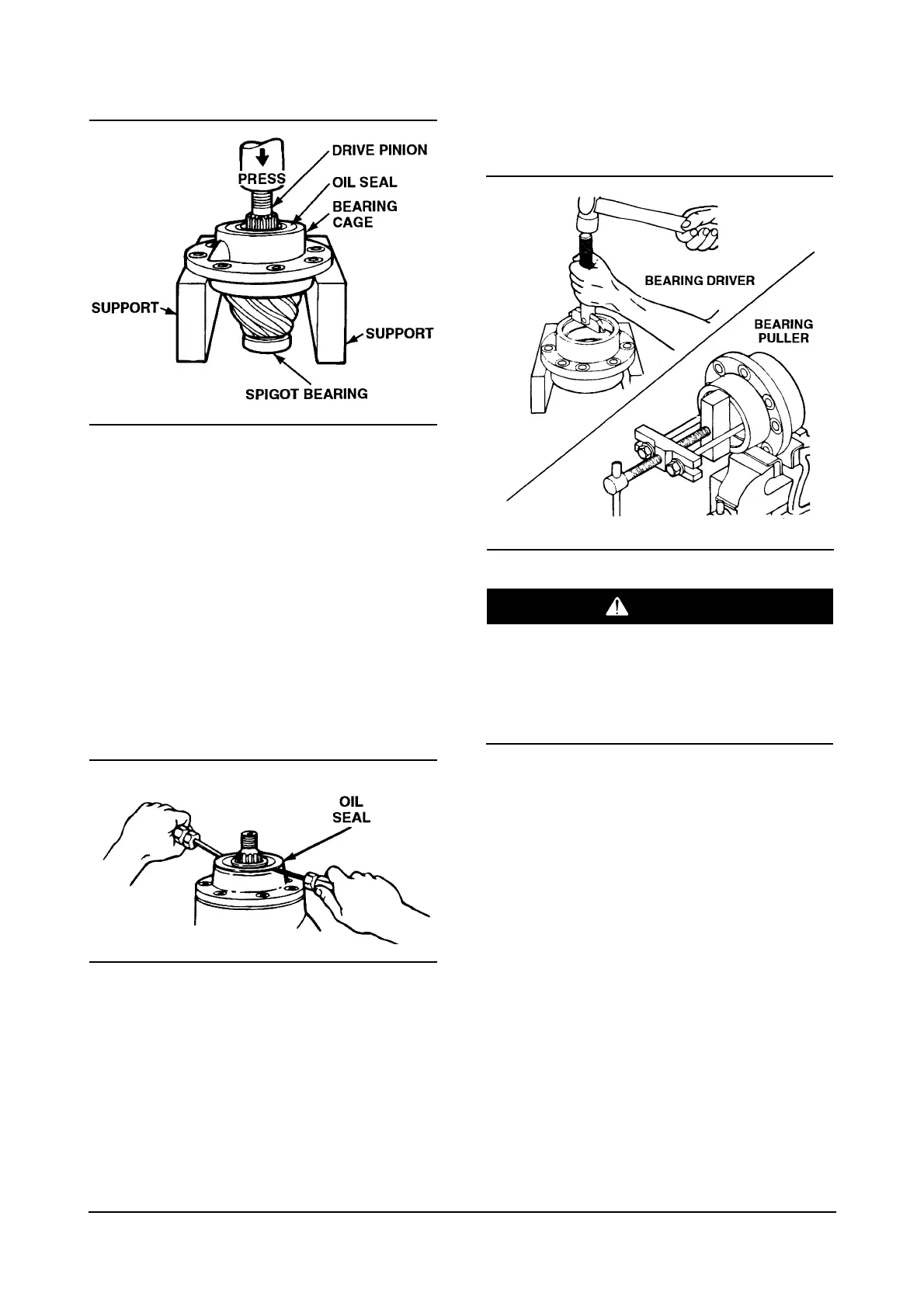

1. Place the drive pinion and bearing cage in a press.

The pinion shaft must be toward the top of the

assembly.

2. Support the bearing cage under the flange area

with metal or wood blocks.

3. Press the drive pinion through the bearing cage.

NOTE : The inner bearing cone and bearing spacer

will remain on the pinion shaft.

4. If a press is not available, use a leather, plastic or

rubber mallet to drive the pinion through the

bearing cage.

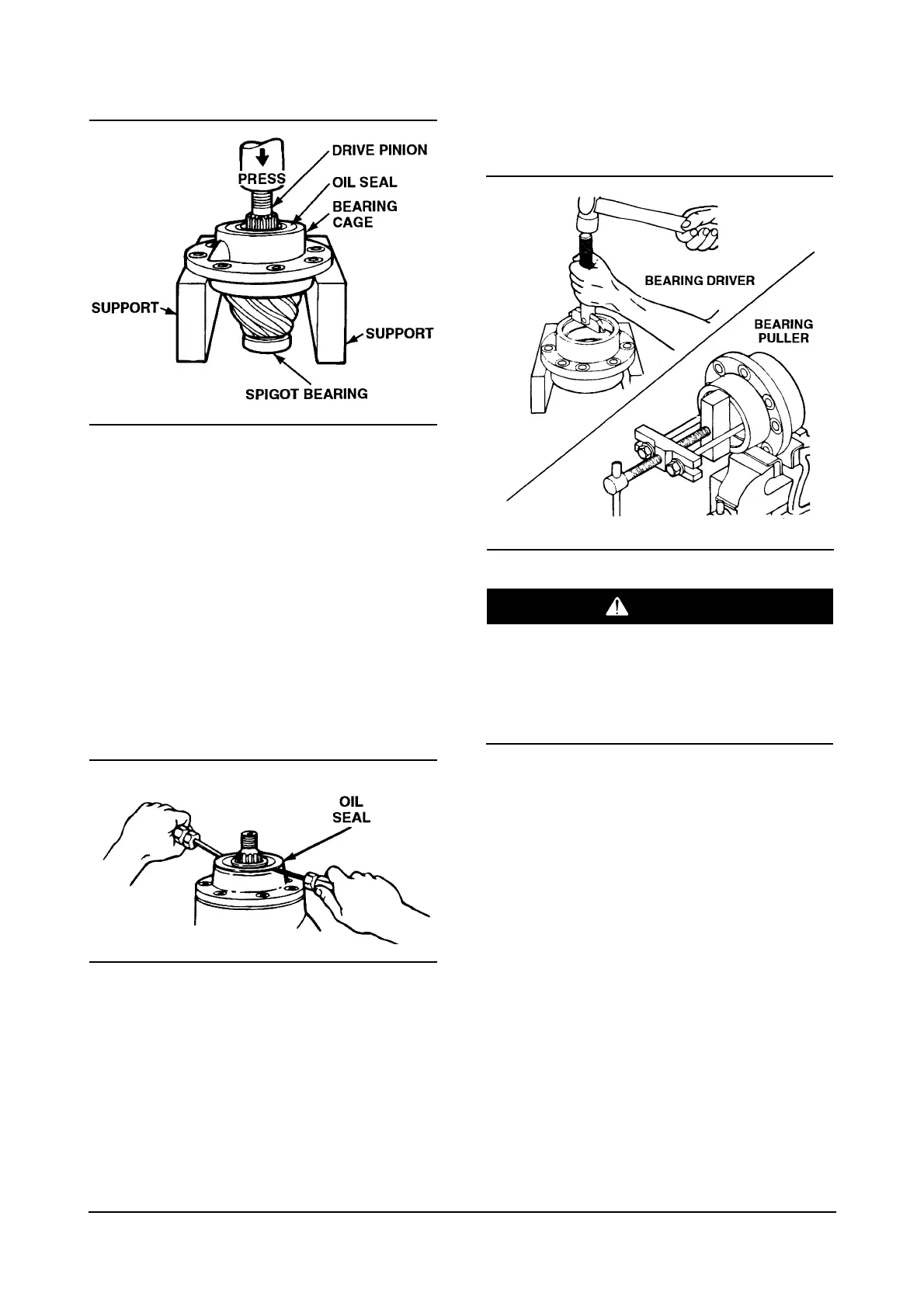

CAUTION : Be careful when removing the seal. Do

not damage the wall of bore. Damage to the bore

wall can result in oil leaks.

NOTE : When the oil seal has been removed, always

replace it with a new seal during component

reassembly.

5. If the pinion oil seal is mounted directly in the outer

bore of the bearing cage, remove the seal at this

time.

Be careful that you do not damage the mounting

surfaces of the bearing cage.

Observe all WARNINGS and CAUTIONS provided

by the press manufacturer conerning press

operation to avoid serious personal injury and

possible damage to components during assembly

and installation procedures.

6. If the pinion bearings need to be replaced, remove

the inner and outer bearing cups from the inside of

cage. Use a press and sleeve, bearing puller or a

small drift hammer.

Loading...

Loading...