Power Train Disassembly & Assembly

Do not hit steel parts with a steel hammer during

removal and disassembly procedures. Striking

parts with a hammer can cause the parts to break

and result in serious personal injury.

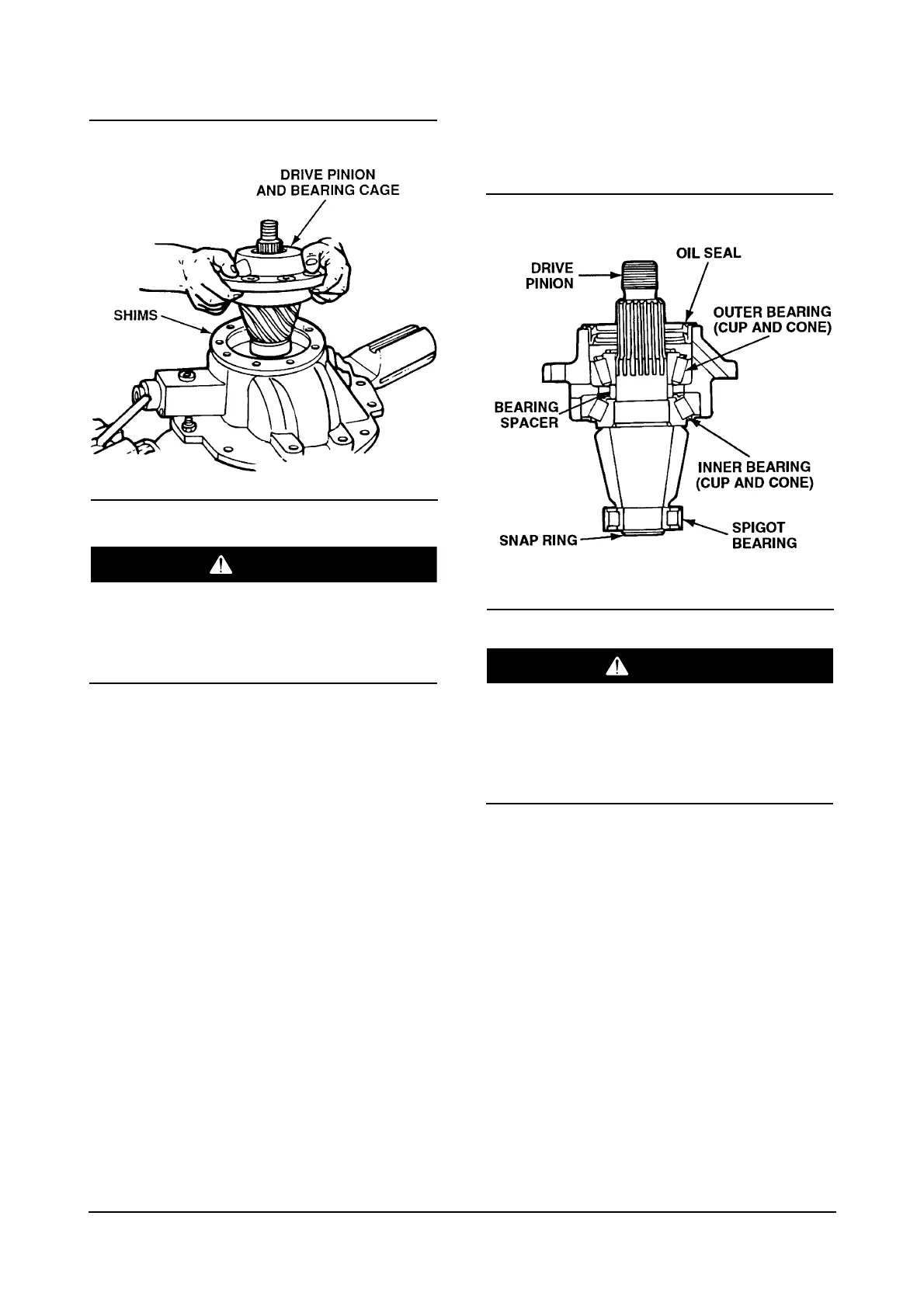

CAUTION : Do not use a pry bar to remove the

bearing cage from the carrier. A pry bar can damage

the bearing cage, shims and carrier.

6. Remove the drive pinion, bearing cage and shims

from the carrier. If the bearing cage is tight in the

carrier, hit the bearing cage at several points

around the flange area with a leather, plastic or

rubber mallet.

7. If the shims are in good condition, keep the shims

together for use later when the carrier is

assembled.

8. If shims are to be discarded because of damage,

first measure the total thickness of the pack. Make

a note of the dimension. This dimension will be

requried to calculate the depth of the drive pinion

in the carrier when the gear set is installed.

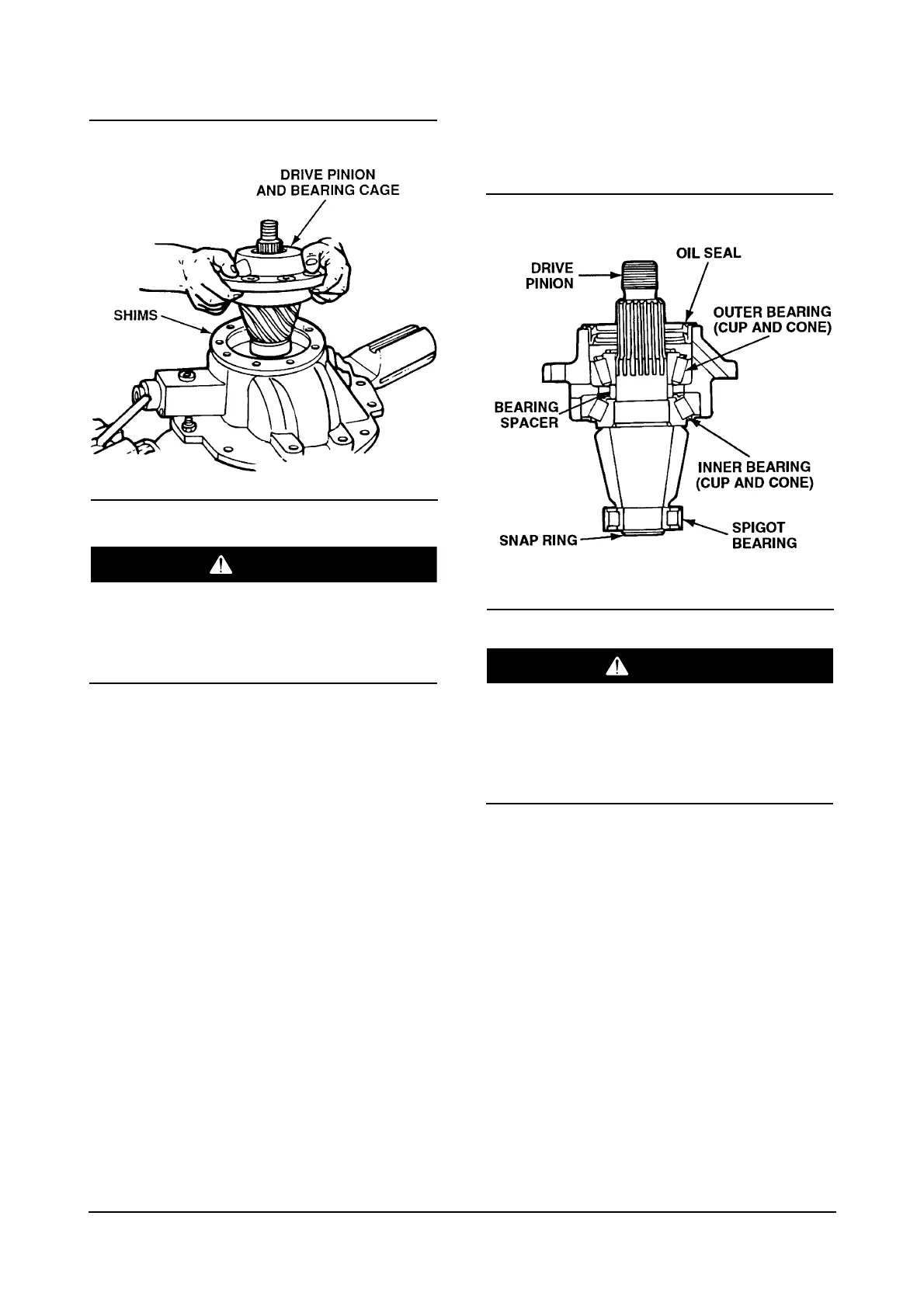

Disassemble the Drive Pinion

and Bearing Cage

Observe all WARNINGS and CAUTIONS provided

by the press manufacturer concerning press

operation to avoid serious personal injury and

possible damage to components during assembly

and installation procedures.

Loading...

Loading...