Power Train Disassembly & Assembly

a. Remove the drive pinion and bearing cage from

the carrier. Refer to the procedure on page 14.

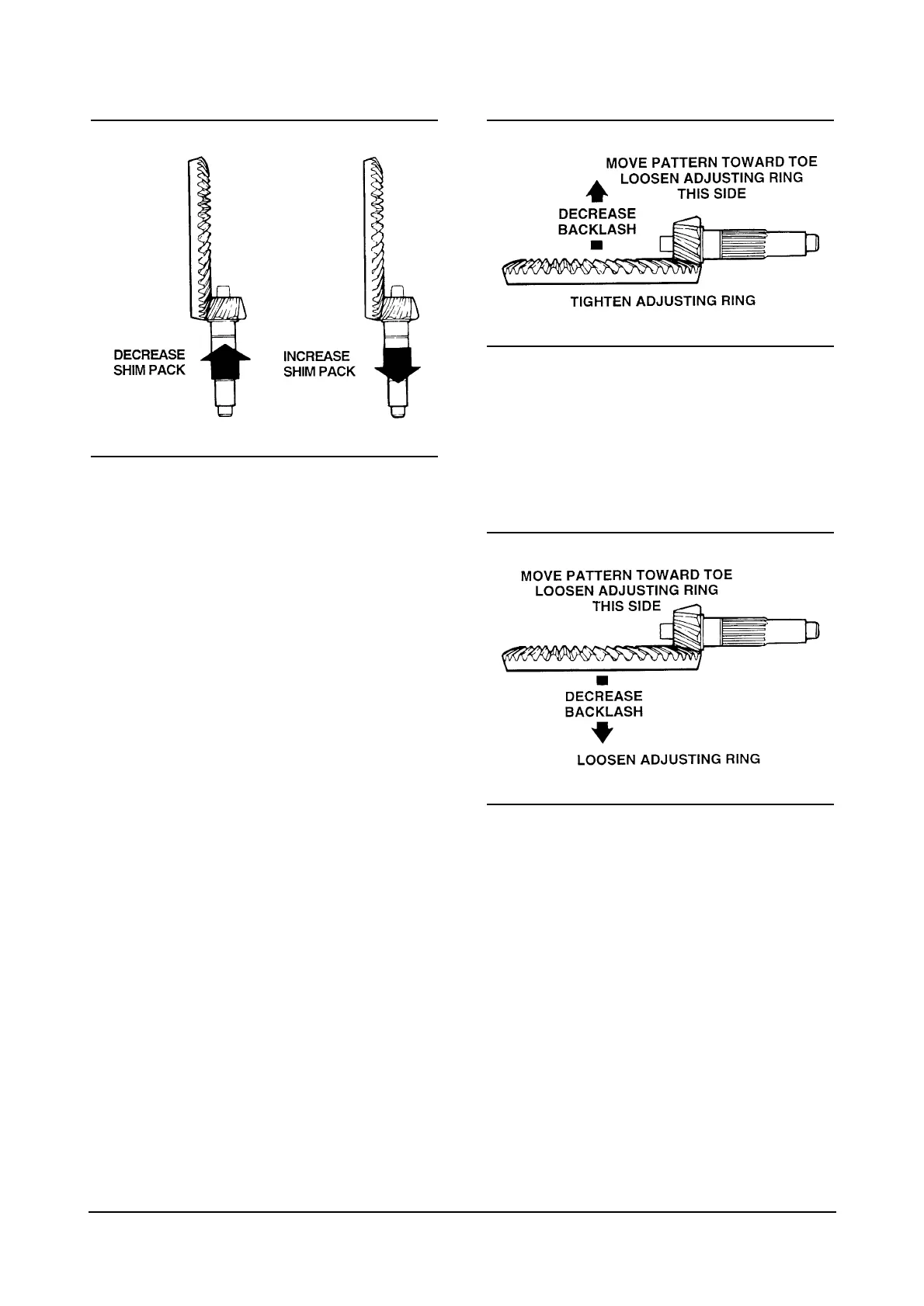

b. To correct a high contact pattern, decrease the

thickness of the shim pack under the bearing

cage. When decreasing the thickness of the shim

pack, the drive pinion will move toward the ring

gear.

To correct a low contact pattern, increase the

thickness of shim pack under the bearing cage.

When increasing the thickness of the shim pack,

the drive pinion will move away from the ring gear.

c. Install the drive pinion, bearing cage and shims

into the carrier, Refer to the procedure on page 24.

d. Repeat steps 2-5 until the contact patterns are in

the center between the top and bottom of the gear

teeth.

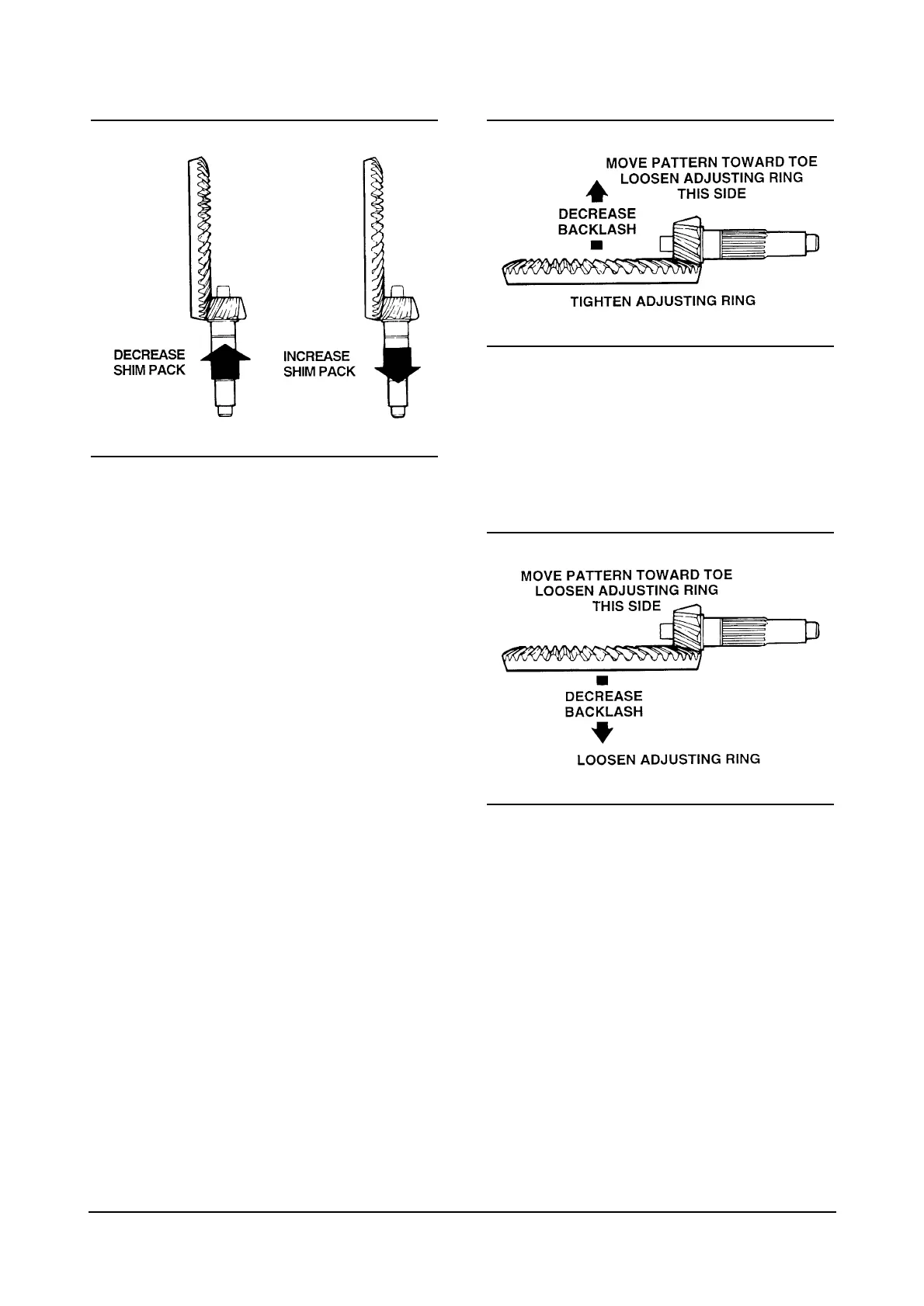

6. Adjust backlash of the ring gear within

specification range to move the contact patterns to

the correct location in the length of the gear teeth.

Refer to the procedure on page 36.

a. Decrease backlash to move the contact patterns

toward the toe of the ring gear teeth.

b. Increase backlash to move the contact patterns

toward the heel of the ring gear teeth.

c. Repeat steps 2-4 and 6 until the contact patterns

are at the correct location in the length of the gear

teeth.

7. Install cotter keys that hold the two bearing

adjusting rings in poistion. Use the following

procedures.

40

Loading...

Loading...