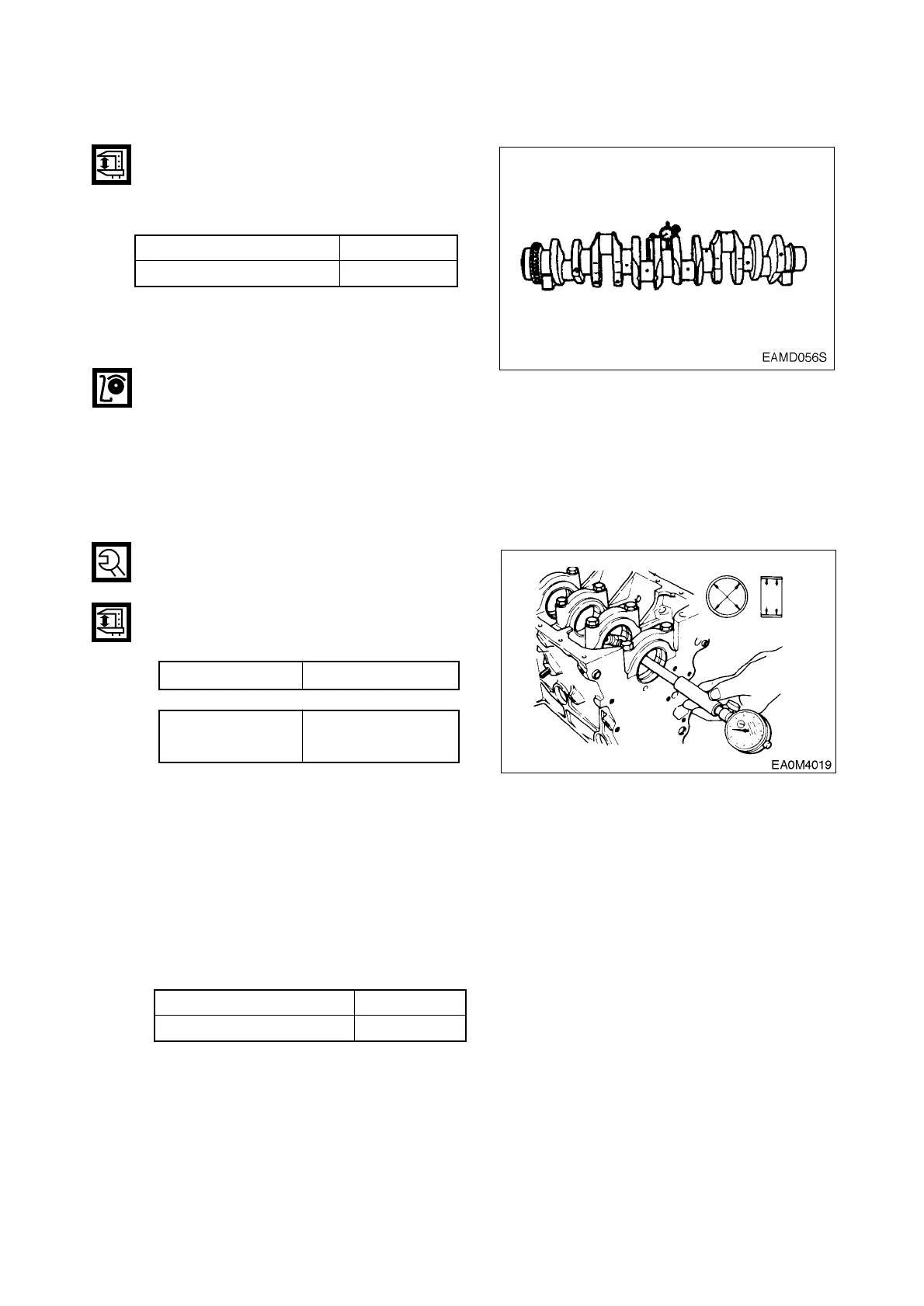

(3) Crankshaft run-out

•

Support the crankshaft on V blocks.

•

Turn the crankshaft with a dial indicator

placed on the surface plate and take the

amount of crankshaft run-out.

2) Crankshaft bearing and connecting rod

(1) Visual check

Visually check the crankshaft bearing

and connecting rod bearing for scores,

uneven wear or damage.

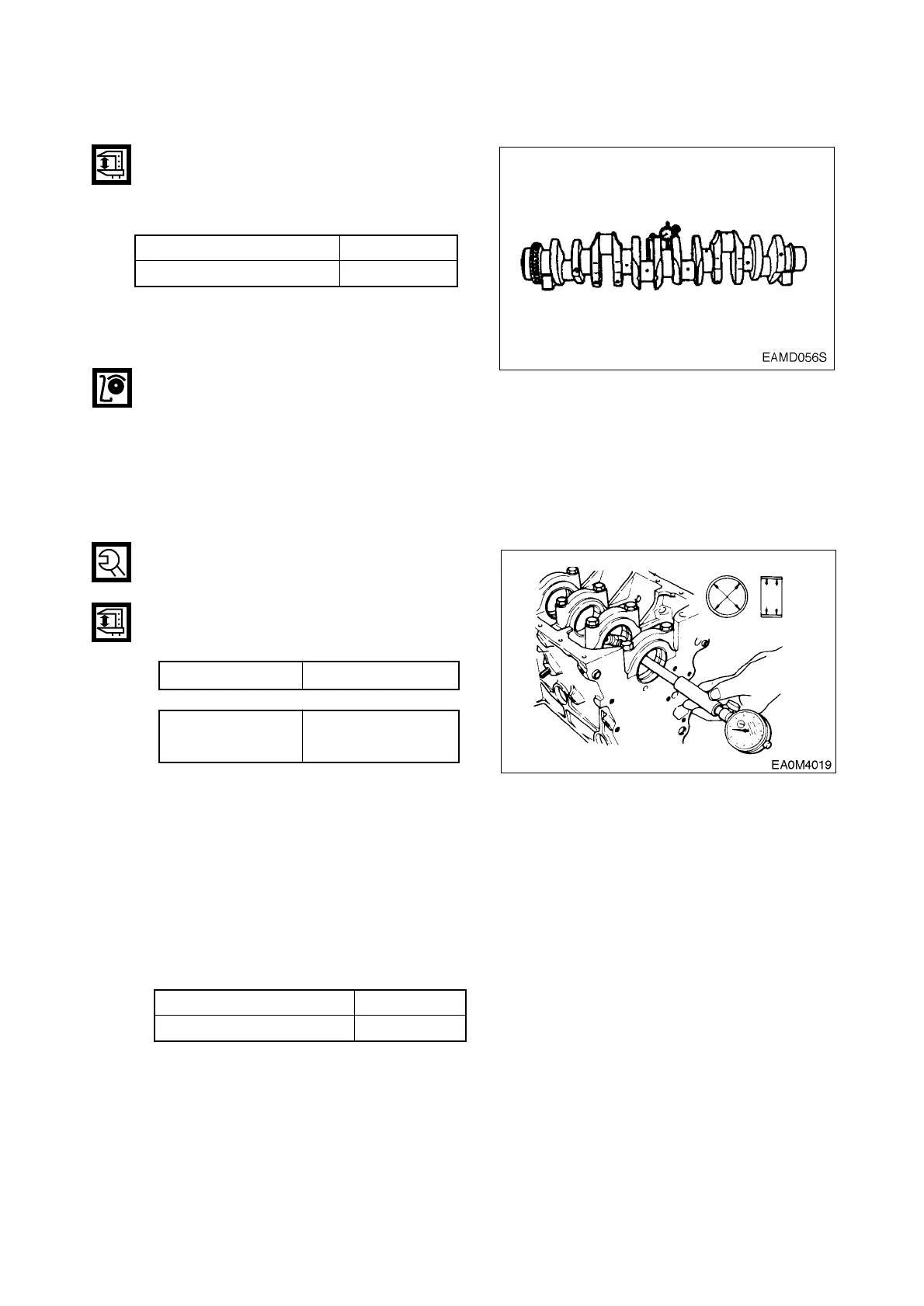

(2a) Oil clearance between crankshaft

and bearing (Method 1 : dial gauge)

•

Main bearing clearance

Install the main bearing in the cylinder

block, tighten the bearing cap to speci-

fied torque, then measure the inside

diameter.

Compare the two values

obtained through measurement of

main bearing inside diameter with

the outside diameters of crank-

shaft journals to determine the oil

clearance.

<Main bearing oil clearance>

- 90 -

Standard Limit

0.05 mm 0.1 mm

Torque 30 kg

.

m

Crank journal 83.966 ~

diameter 83.988mm

Standard Limit

0.052 ~ 0.122 mm 0.25 mm

Loading...

Loading...