5. About the engine

92

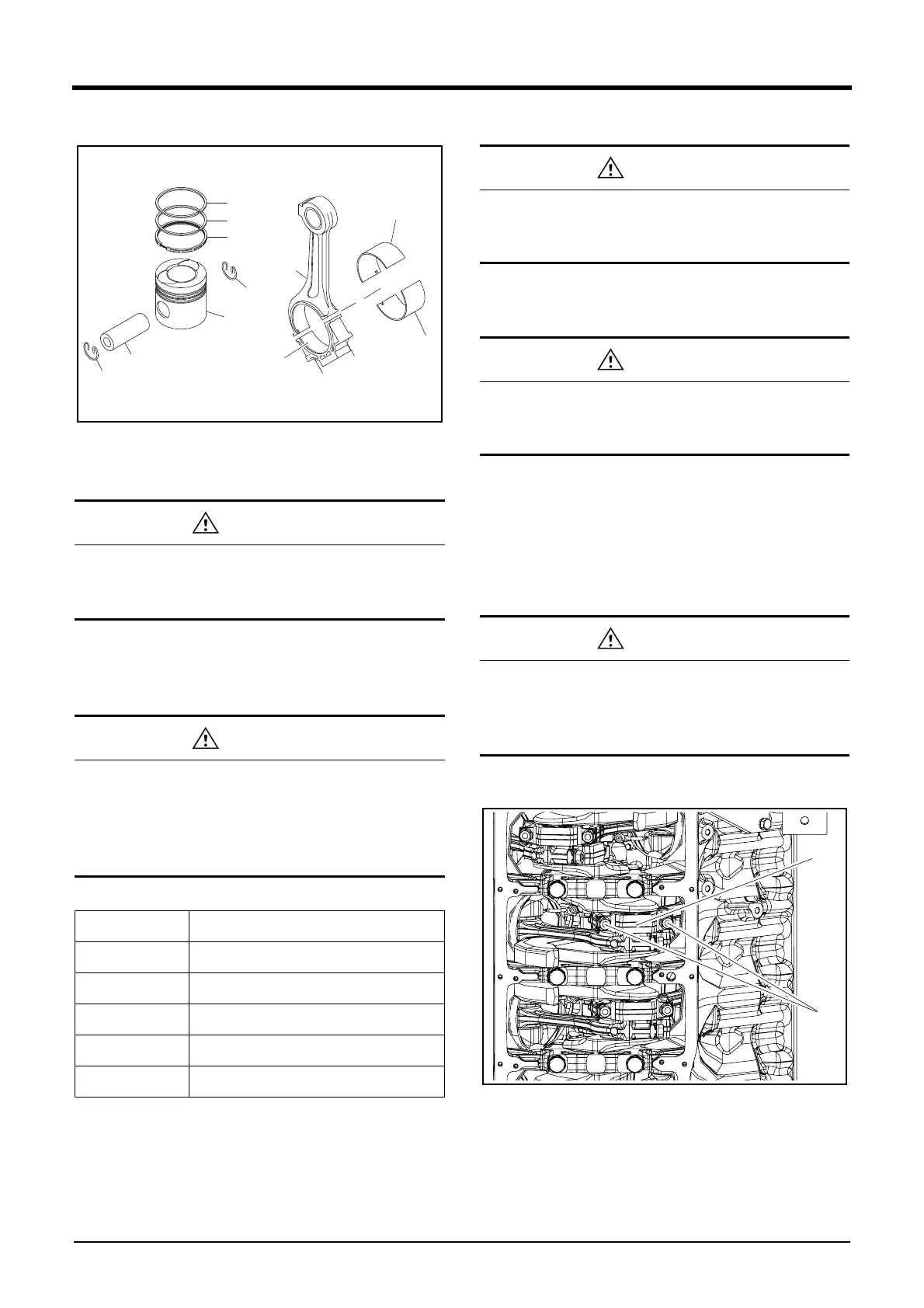

12. Attach the piston to the connecting rod.

DV2213177A

1) Install the 1st ring(D), 2nd ring(E), and the oil ring(F) with

the piston ring plier(T7621010E).

2) Apply engine oil on the piston pin(C).

3) Align the pin hole of the connecing rod(G) small-end with

that of the piston(A).

4) Attach the piston pin(C).

5) Attach 2 snap rings(B) with the snap ring plier

(T7610001E).

6) Align the upper bearing groove with connencting rod.

Attacht the upper connecting rod bearing(I) to the

connecting rod(G).

7) Align the lower bearing groove with connecting rod.

Attach the lower connecting rod bearing(J) to the

connecting rod bearing cap(H).

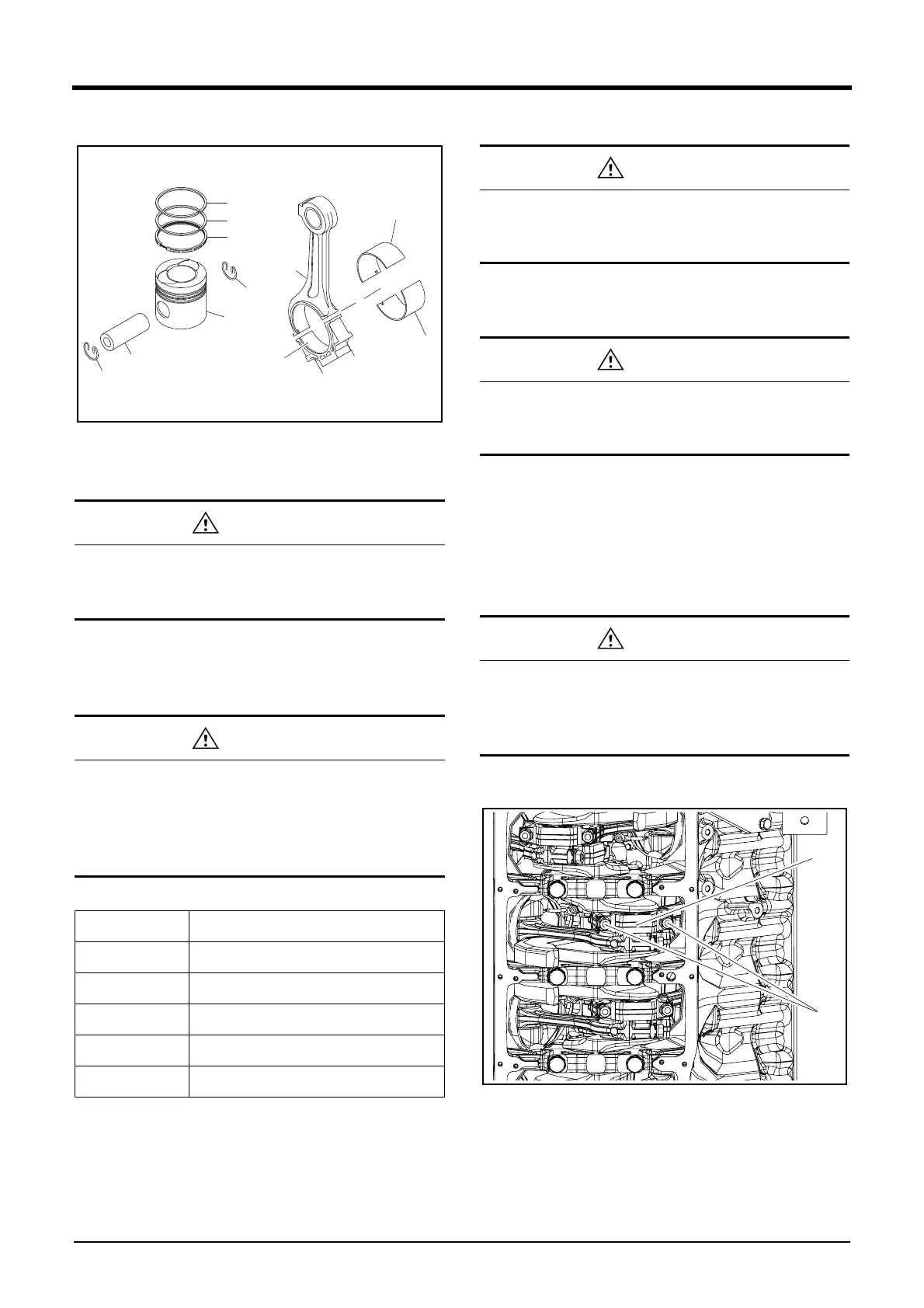

13. Attach the connecting rod and piston assembly.

DV2213088A

1) Attach the connecting rod and piston assembly to the

cylinder block.

2) Attach the connecting rod cap(B).

3) Tighten 2 M16X1 flange hex bolts(A) at a tightening

torque 10 kgf·m + 90° by using the angle method.

• Ensure that the ‘Y’ mark of the piston ring faces the

top surface of the piston.

• Make the piston ring position dislocated to 120°

• The intake valve pocket is larger than the exhaust

valve pocket.

• Attach the engine as the same piston weight. Place

the Class of the piston weight on the top surface of

the piston.

CLASS Piston Weight(g)

A 2,371 ~ 2,380

B 2,381 ~ 2,390

C 2,391 ~ 2,400

D 2,401 ~ 2,410

E 2,411 ~ 2,420

Check the attached piston and piston ring. If the piston

should be replaced, replace the piston pin along with

the piston.

• Do not reuse the snap rings.

• Assemble snap rings with the opening of the snap

rings facing 12 o’clock.

• Be careful the direction when assembling the

connecting rods and the connecting rod caps.

• Ensure that the marks of the connecting rod and the

bearing cap are facing the same direction.

Loading...

Loading...