5. About the engine

93

4) Attach 12 connecting rod and piston assembly as the

same procedure.

14. Attach the oil suction pipe and the oil pump.

DV2213087A

1) Attach the oil suction pipe and the oil pump(D).

2) Tighten M8 fixing bolt(C) at a tightening torque 2.2 kgf·m.

3) Tighten 2 M8 fixing bolts(B) at a tightening torque

2.2 kgf·m.

4) Tighten 2 M8 fixing bolt(A) at a tightening torque

2.2 kgf·m.

15. Attach the oil pan.

DV2213086A

1) Attach the oil pan(B).

2) Tighten 20 M8 fixing bolts(A) at a tightening torque 2.2 ±

0.33kgf·m.

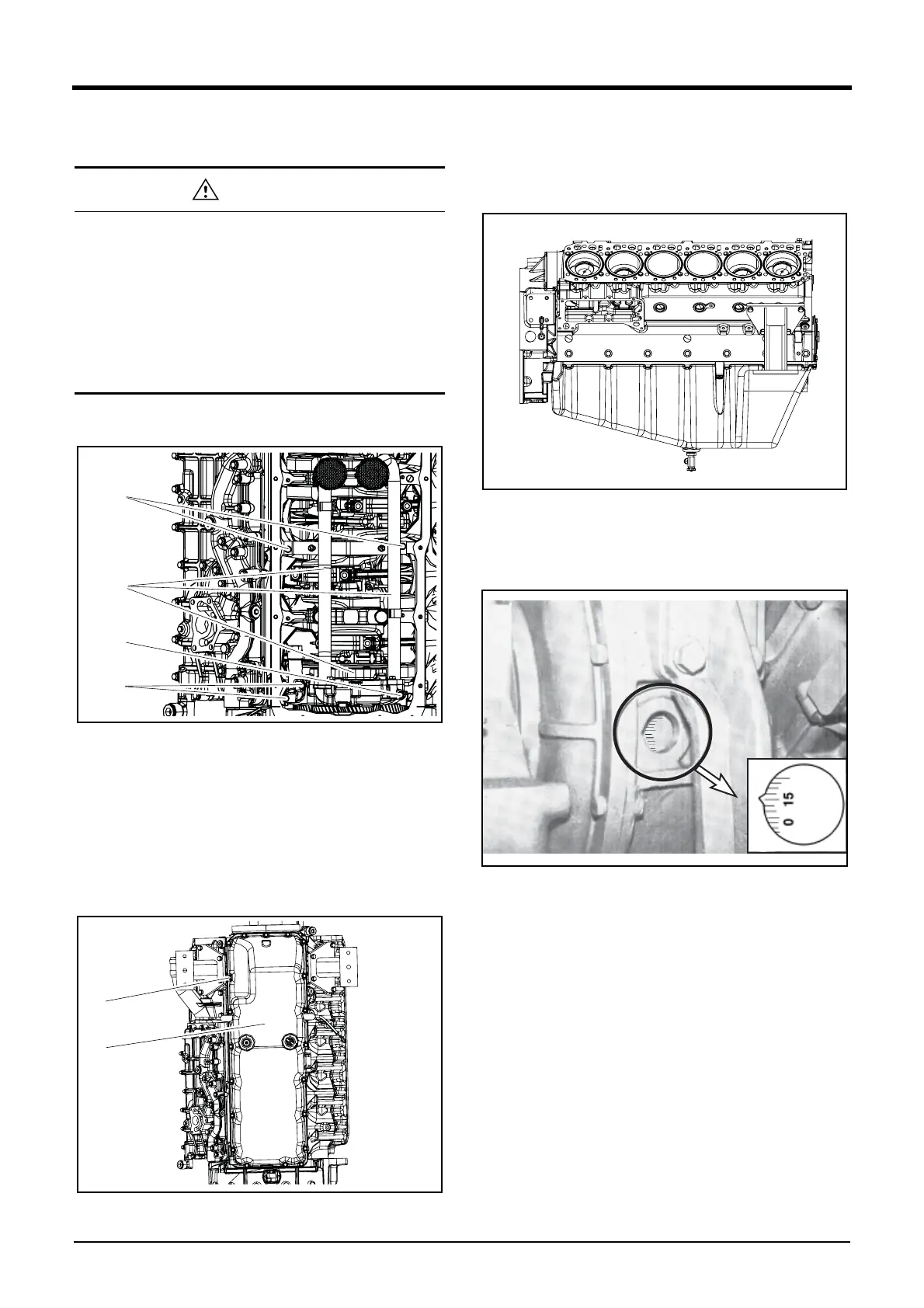

16. Change the engine position.

DV2213185A

1) Change the engine positon. The piston direction is

upward.

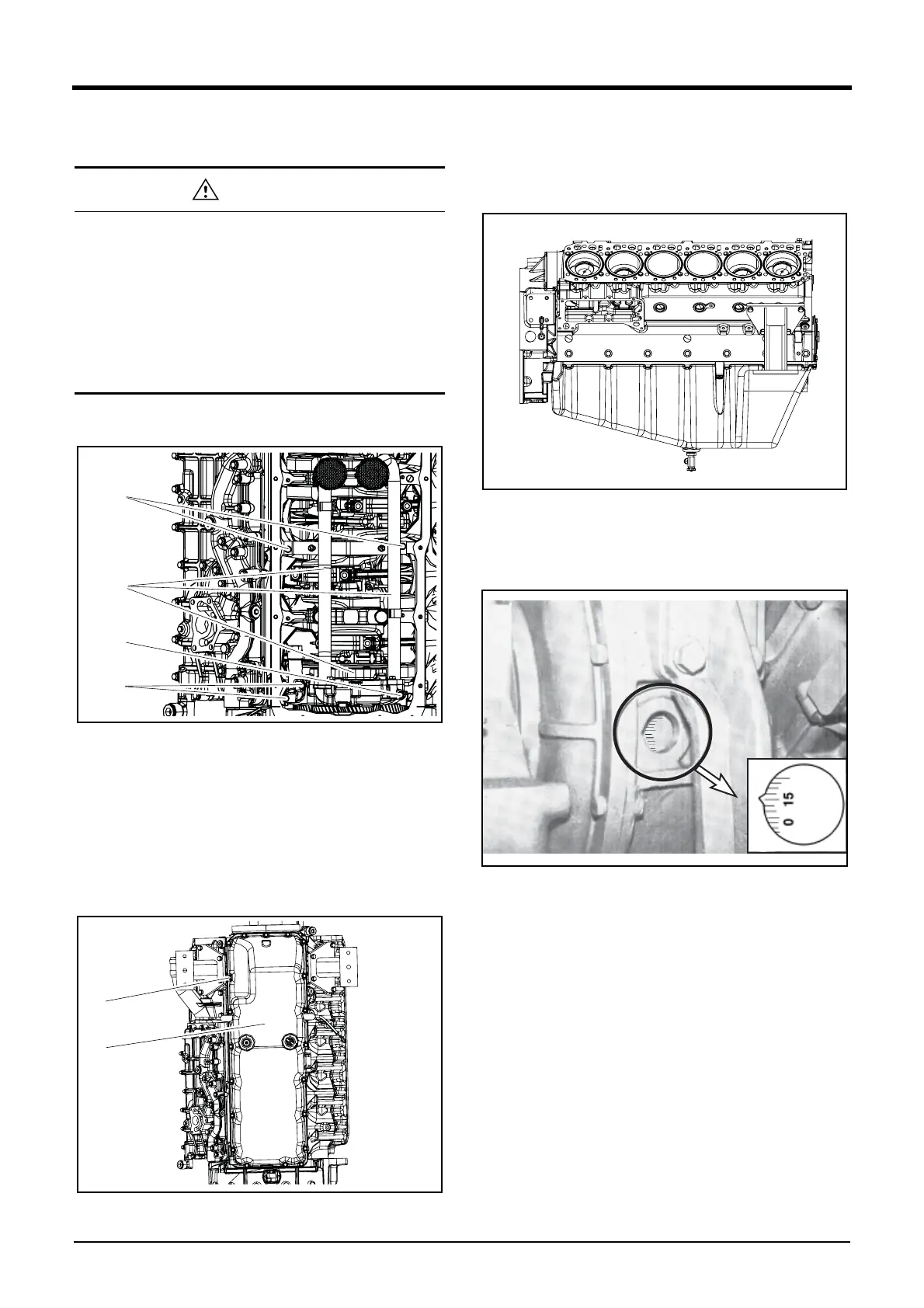

17. Adjust the fuel injection timing.

DV2213027A

1) Rotate the crankshaft so that the #1 cylinder piston may

be positioned at the top dead center(OT) and the #6

cylinder piston may be posiitioned at the valve overlap.

Note) In case of 8/12 cylinder engine, #6. cylinder is posi-

tioned at the valve overlap when #1. cylinder is posi-

tioned at the compression TDC(Top Dead Center).

Note) In case of 10 cylinder engine, #7. cylinder is positioned

at the valve overlap when #1. cylinder is positoned at

the compression TDC(Top Dead center).

2) Rotate the crankshaft until the yellow mark of the

camshaft gear is not shown.

3) Adjust the fuel injection timing with rotating the flywheel

to the engine rotating direction.

• Be careful to note the direction when attaching the

connecting rods and the connecting rod caps.

Ensure that the number engraved on the connecting

rods is same with that engraved on the connecting

rod caps and the assembly direction is same.

• Attacht the connecting rod and piston assembly

without contacting the crankshaft weight. Rotate

the crankshaft.

Loading...

Loading...