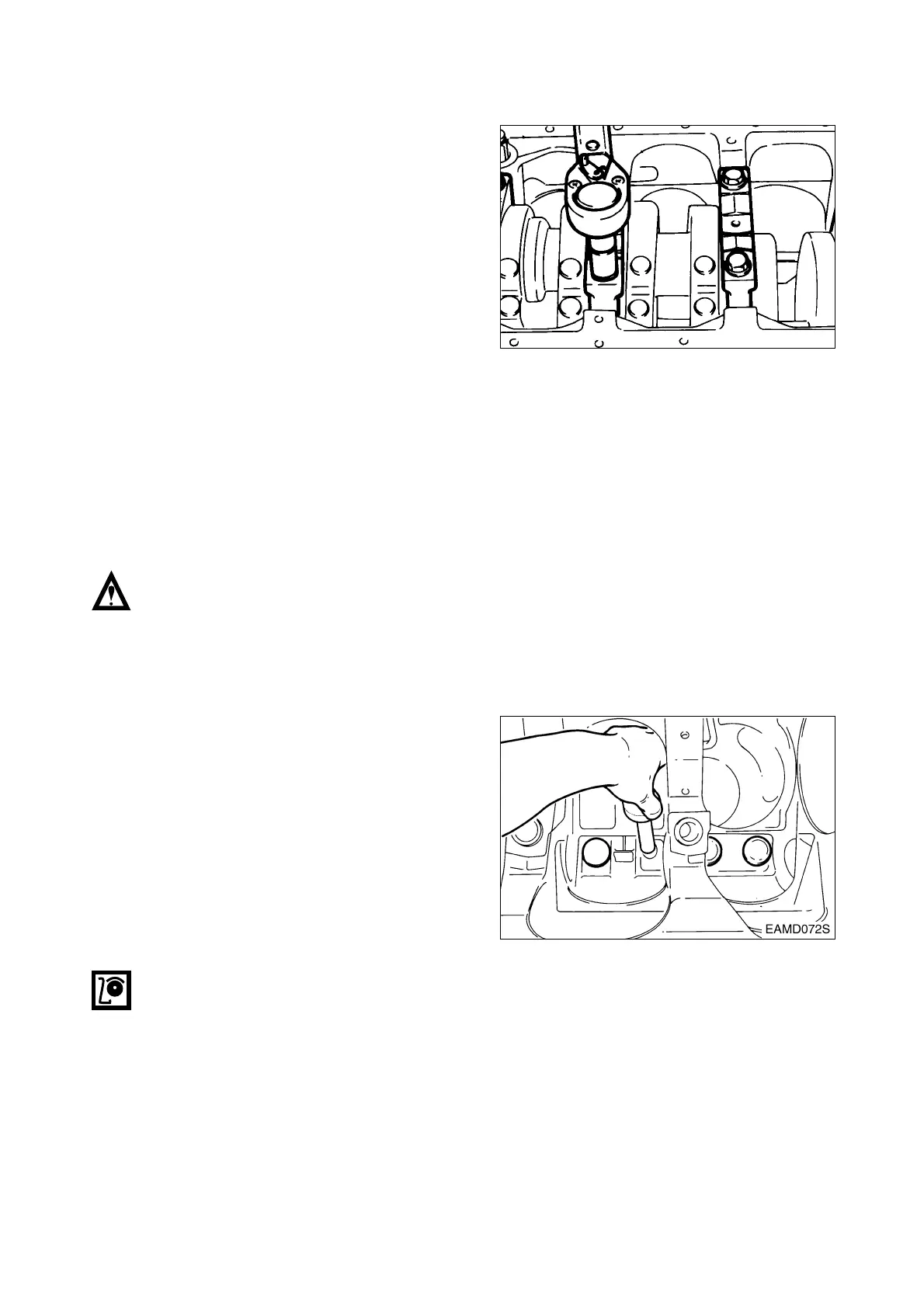

9.1.36. Bearing cap

•

Remove the bearing cap assem-

bling bolts by the step in the reverse

order of assembling, and disassemble

the bearing cap. (Remove by the same

way as the cylinder head bolts’

removal.)

•

Disassembled bearing caps are kept

laid in order.

9.1.37. Crankshaft

•

Assemble the bolts on the both side of crankshaft temporarily.

•

Connect the rope to the bolts and lift the crankshaft by means of crane being careful not to

give any damage on it.

•

In order for the disassembled crankshaft to be prevented from bends or damage, put it on

the special lathe and store.

•

Disassemble the metal bearings in turn and store them.

Note : Do not mingle with the metal bearings and bearing caps randomly. To prevent mix-

ing, temporarily assemble the metal bearings to the corresponding bearing caps in

turn.

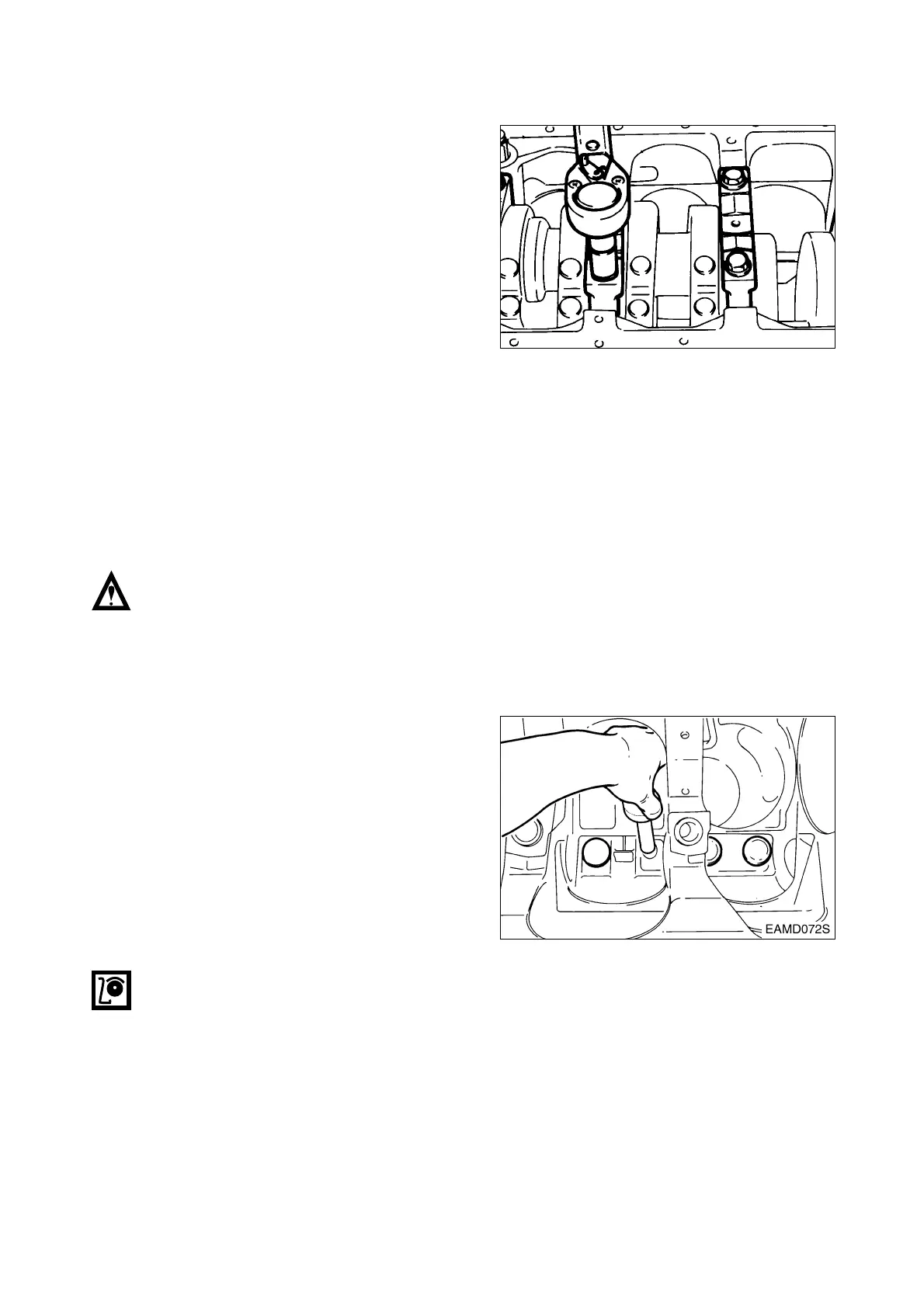

9.1.38. Camshaft and tappet

•

In order for camshaft not to be dam-

aged, disassemble turning it.

•

In order for the disassembled

camshaft to be prevented from bends

or damage, put it on the special lathe

and store.

•

Pull out the tappet.

•

As required, pull out the camshaft

bush from the cylinder block by a

press.

•

Check for damage, scratch, and wear-

ing state and if abnormal, tear down.

- 77 -

EAMD047S

Loading...

Loading...