©

DOSATRON INTERNATIONAL / 41

©

DOSATRON INTERNATIONAL / 41

EN

©

DOSATRON INTERNATIONAL / 40

Maintenance

RECOMMENDATIONS

HOW TO DRAIN THE DOSATRON (in case of freezing temperature)

- Turn off the water supply and let the pressure drop to zero.

- Remove the injection assembly, see § CHANGING THE MOTOR PISTON.

- Remove the bell and the motor piston.

- Disconnect the water inlet and outlet fittings.

- Remove the lower pump body from the mounting bracket and empty any

remaining water.

- The DOSATRON can now be reassembled, having first cleaned the seal.

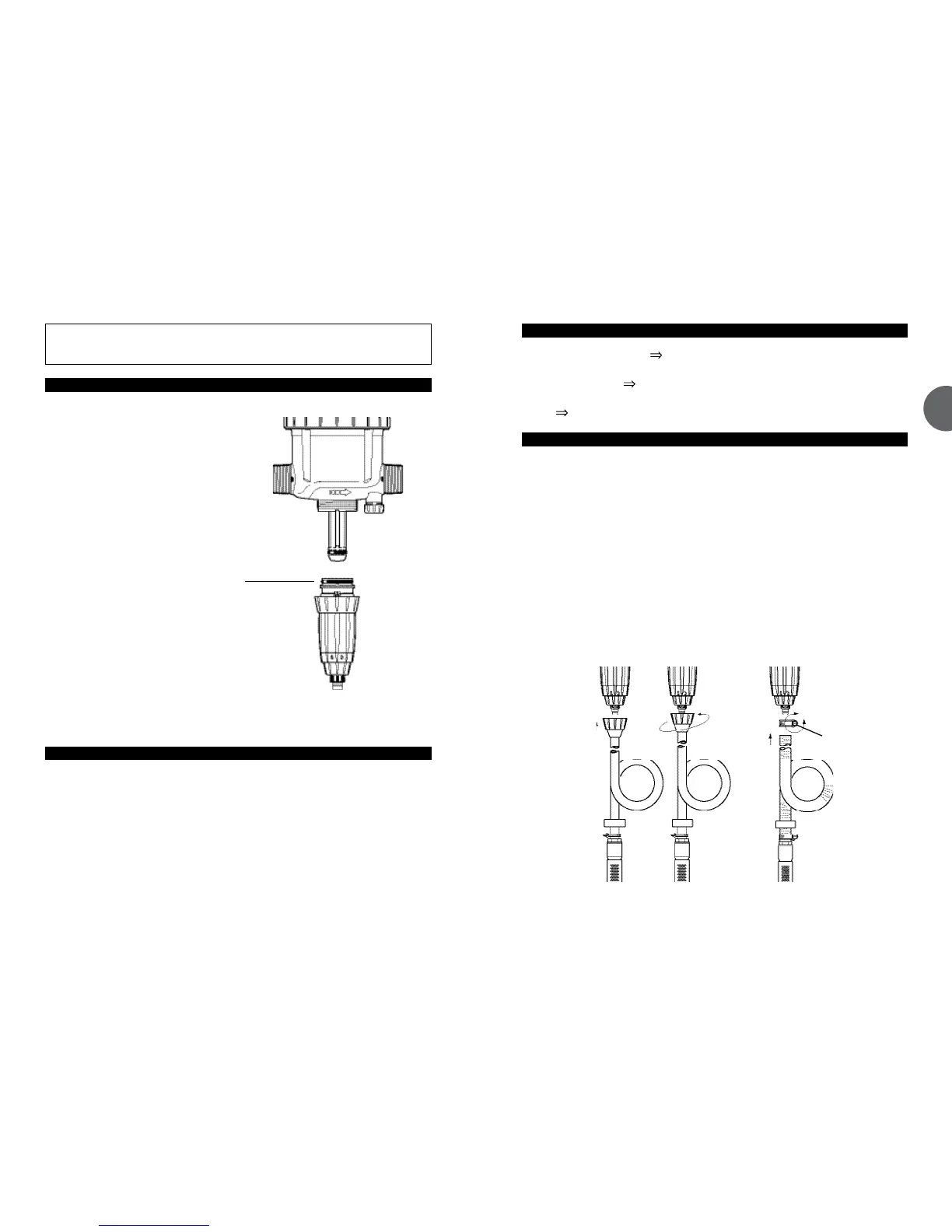

Fig. 7

O-ring

INTERNATIONAL CONVERSIONS

Principle : Setting at 1% 1/100 = 1 part of concentrate for 100 parts

of water.

Ex. : Setting at 2%

2/100 = 2 parts of concentrate for 100 parts

of water.

Ratio

1/50.

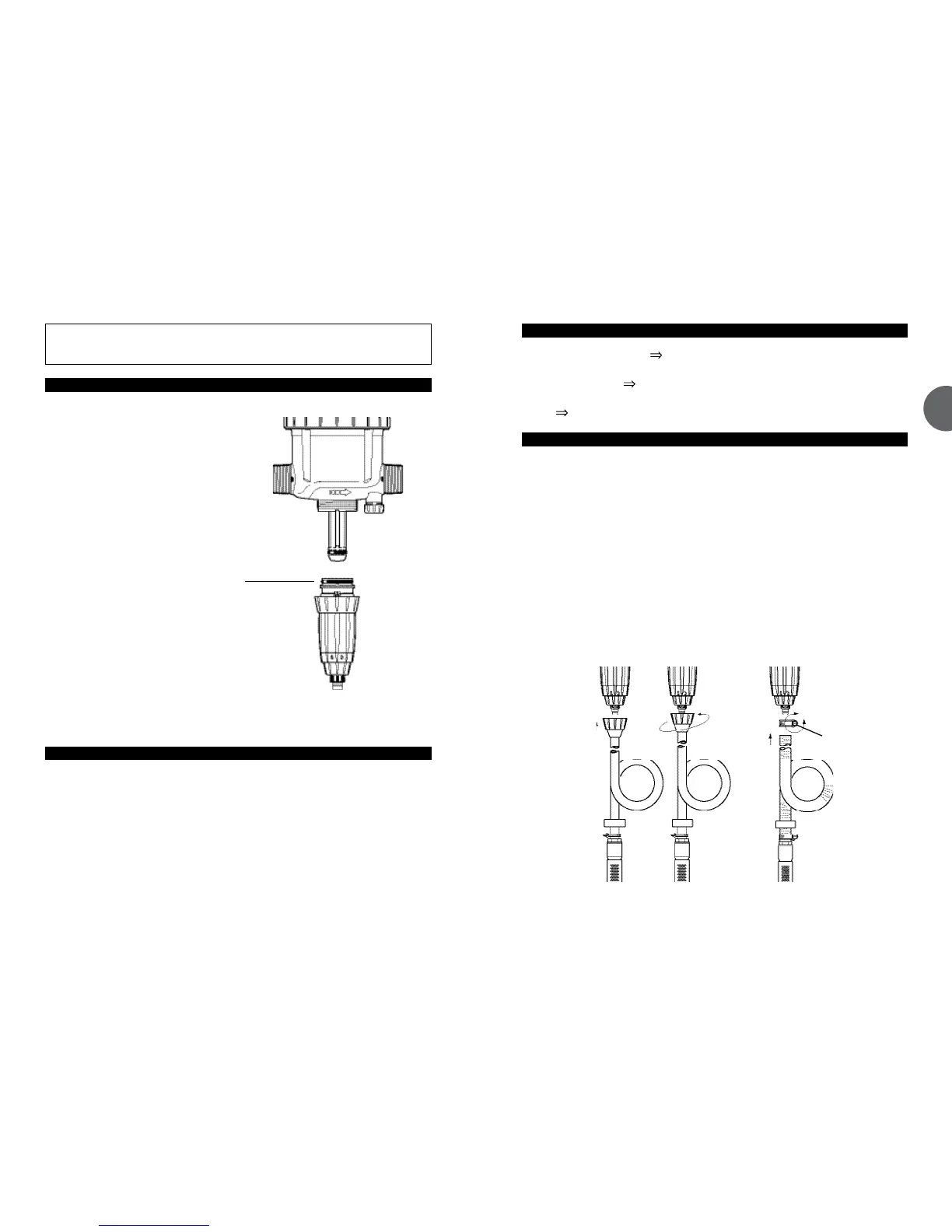

FITTING THE SUCTION TUBE

Fig. 11 Fig. 12

If the DOSATRON has already been used, please imperatively refer to

§ PRECAUTIONS.

For Ø 16 (Fig. 11) :

- Unscrew the nut at the bottom of the injection assembly and put it onto

the tube.

- Push the hose firmly into the barbed fitting and re-tighten the collar.

For Ø 20 (Fig. 12) :

- Using a screwdriver, unscrew the collar (Fig. 12-C) mounted on the

suction hose.

- Push the hose firmly into the barbed fitting and re-tighten the collar.

Ø 16 Ø 16 Ø 20

C

1 - When using soluble products

to be made up into solutions, we

recommend the periodic dismantling

of the entire dosing part (see : §

CLEANING AND REFITTING THE

SUCTION VALVE, § CHANGING

SEALS IN THE INJECTION

ASSEMBLY).

Thoroughly rinsing all the elements

of the dosing part with water and

re-assembling them after having

previously lubricated the seal (Fig. 7)

with a silicone lubricant, in the case

of difficulty in re-fitting.

2 - Before putting the DOSATRON

into operation after a non-use

period, remove the motor piston and

soak it into lukewarm water

< 40° C [104° F] overnight. This

helps to dissolve any deposits which

may have dried onto the piston

motor.

Loading...

Loading...