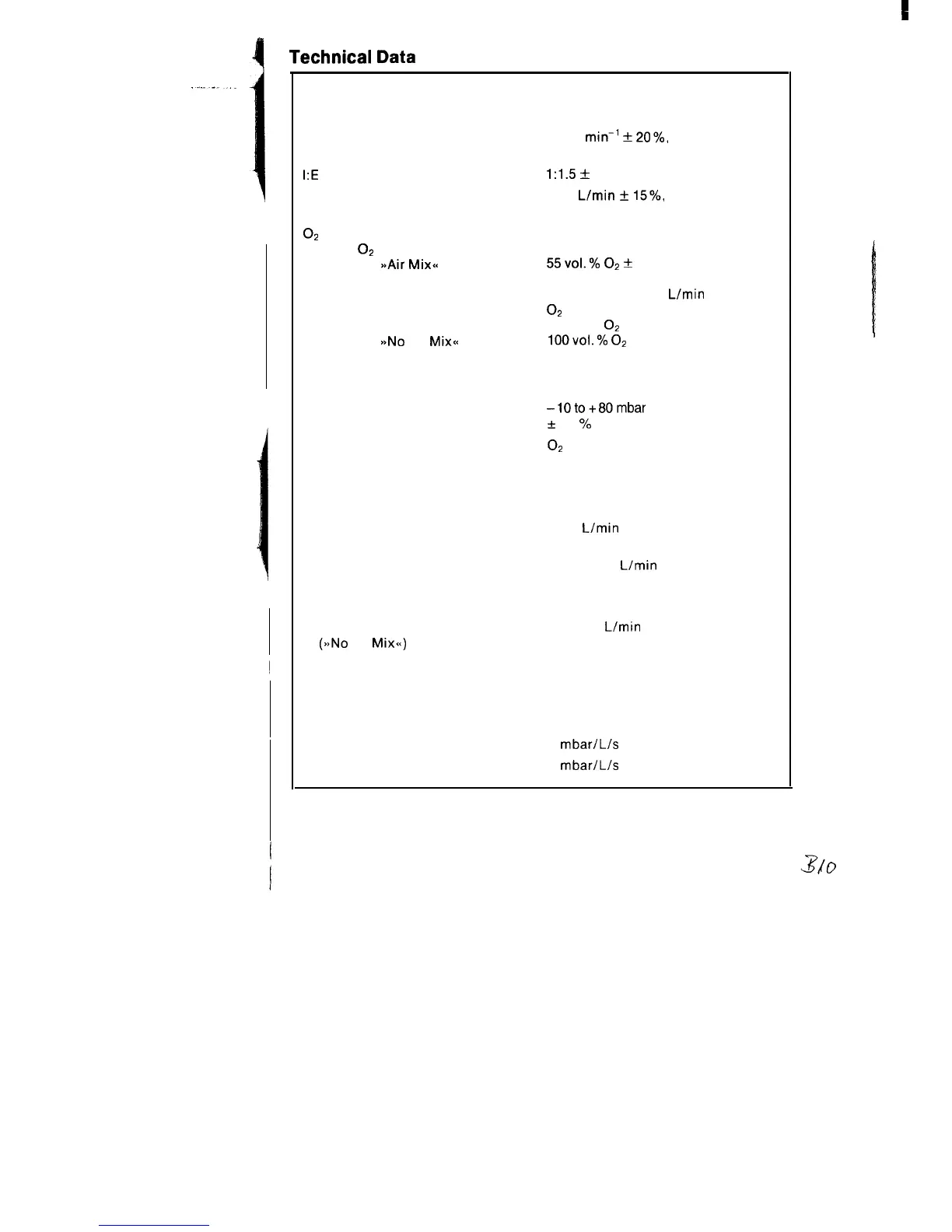

Technical

Data

Principle of operation

Control

Ventilation ratio

I:E

ratio

Minute volume

Flow chopper

Time-cycled, volume-constant

10-35

min-’

+

20%,

infinitely adjustable

1:1.5

+

10%

2-20

L/min

+

15%,

infinitely adjustable

O2

concentration of breathing

gas with

O2

drive

Switch on

SsAir

Mixa

Switch on

>bNo

Air

Mix<<

Safety valve

Opening pressure

Airway pressure reading

55vol.%

02

+

10%

(with MV greater than 7 L/min)

with MV less than 7

L/min

O2

concentration increases up to

80 vol. %

O2

100v0l.%

02

50 mbar to 80 mbar

Pressure gauge

-1Oto+80mbar

+

2.5 % full scale

Drive gas

Quality

Pressure at device inlet

O2

or air

Dry, oil-free and dust-free from a

central supply unit or from com-

pressed-gas cylinders’.

min. 2, max. 6 bar with a flow rate

of 60

L/min

Gas consumption

Control

approx. 0.8

L/min

MV (Air Mix)

approx. 50 % of set MV

MV (No Air Mix)

approx. 100 % of set MV

Typical usage period

with 3 L cylinder/200 bar

MV = 10

L/min

(see also Page 11)

(>aNo

Air

Mix<<)

54 min

Pneumatic main switch

I-O

Patient system

Comprising silicone tubing 1.1 m

a

Non-rebreathing valve

Compressible volume

approx. 3.3 mL/mbar

Inspiration resistance

3

mbar/L/s

Expiration resistance

3

mbar/L/s

22

Loading...

Loading...