DSE Model 521 Remote Start Engine Management System - Operators Manual

DSE 521 ISSUE 4 4/4/02 MR

12

4.2 CONNECTOR FUNCTION DETAILS

The following describes the functions of the 2 connectors on the rear of the module. See rear panel

layout

FIG 5.

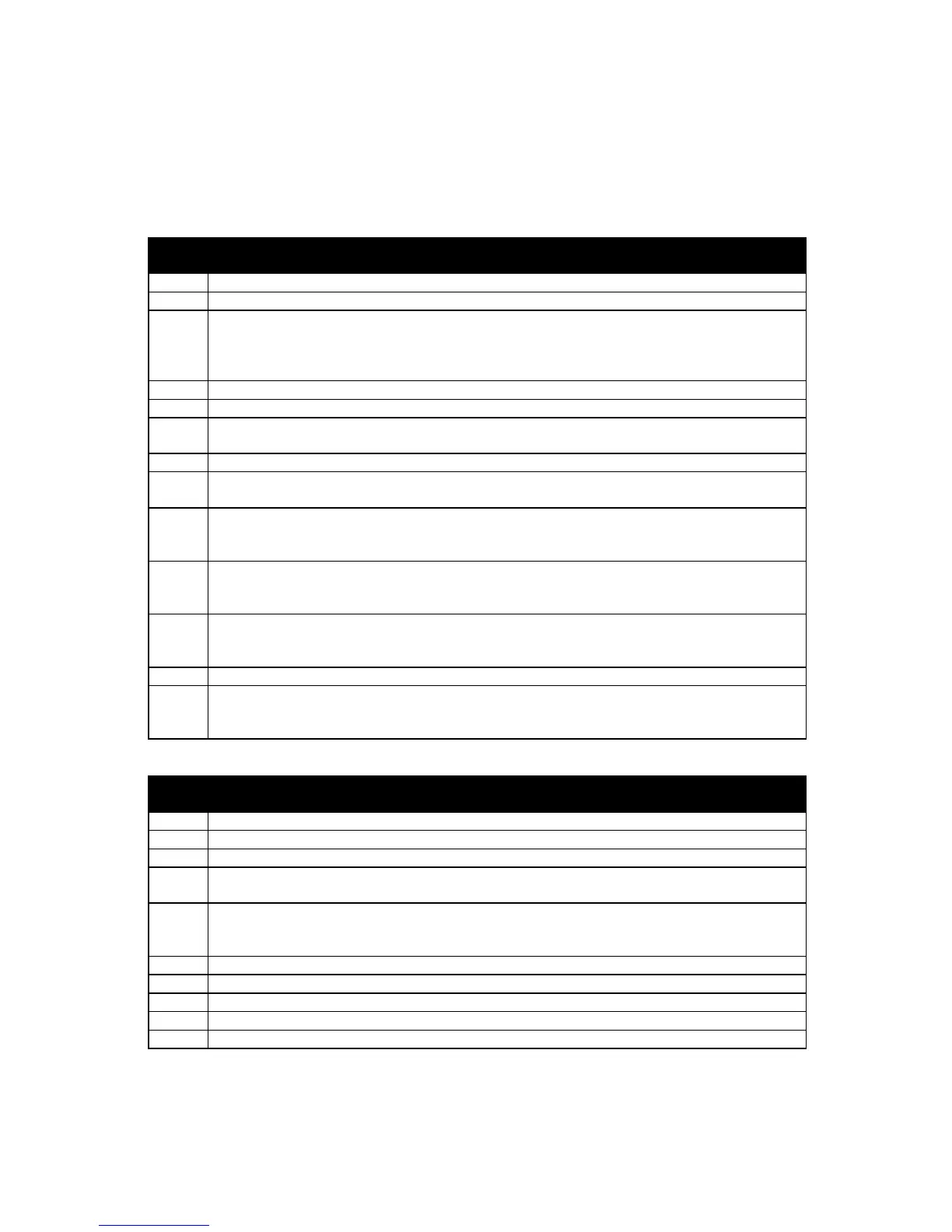

PLUG “A” 13 WAY

PIN

No

DESCRIPTION

1 DC Supply -ve. System DC negative input. (Battery Negative).

2 DC Supply +ve. System DC positive input. (Battery Positive).

3 Emergency Stop input. Internally linked to Starter and Fuel outputs. If this input is

not connected to positive the module will be locked out, and if the engine is

running will shutdown immediately. Positive Supply also removed from Starter and

Fuel therefore only a single pole Emergency Shutdown button is required.

4 Fuel Relay output. Plant Supply +ve from pin 3. Used to control the fuel solenoid.

5 Starter Relay output. Plant Supply +ve from pin 3. Used to control the Starter Motor.

6 Auxiliary Relay output 1. Plant Supply +ve. Configurable output, see Calibration

Manual for options available.

7 Auxiliary Relay output 2. As for Auxiliary output 1 (Pin No 6).

8 Charge Fail input / Excitation output. Supplies excitation to the Plant Battery

Charging Alternator, also an input for the Charge Fail detection circuitry.

9 Low Oil Pressure input. This is a negative switched input, it is possible to calibrate

the input to be a normally closed signal or a normally open signal. This input is

used to signal to the module that the oil pressure is low.

10 High Engine Temperature input. This is a negative switched input, it is possible to

calibrate the input to be a normally closed signal or a normally open signal. This

input is used to signal to the module that the engine temperature is high.

11 Auxiliary input 1. This is a negative switched configurable input, see Calibration

Manual for options available. It is possible to configure the input to be a normally

closed signal or a normally open signal.

12 Auxiliary input 2. As for Auxiliary input 1 (Pin 11).

13 Remote Start input. This is a negative switched input which will start the generator

when Auto is selected. It is possible to configure the input to be a normally open

signal or a normally closed signal.

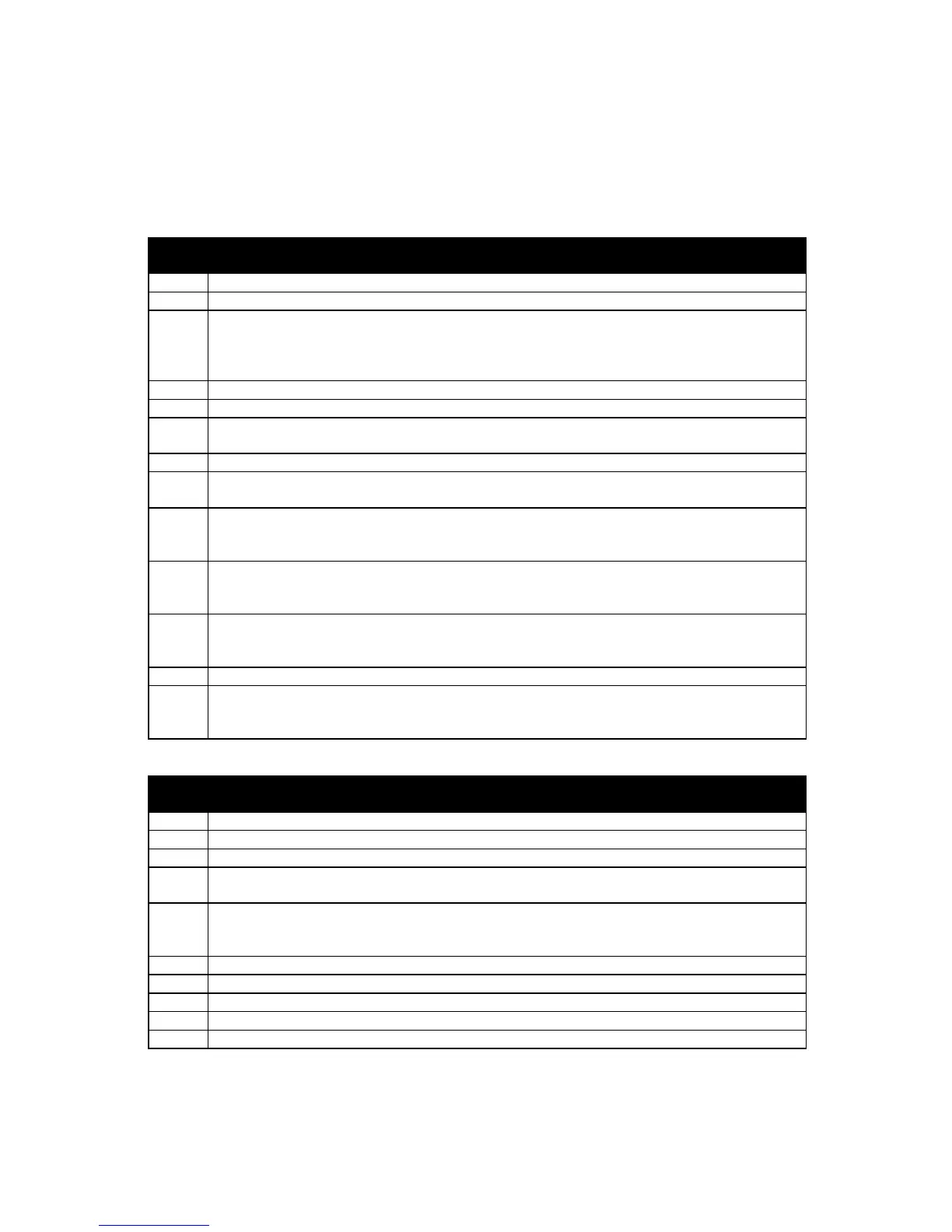

PLUG “B” 10 WAY

PIN

No

DESCRIPTION

14 Alternator Input L1. Used for Alternator speed sensing.

15 Alternator Input N. Used for Alternator speed sensing.

16 DO NOT USE

17 Auxiliary Relay output 3. Plant Supply +ve. Configurable output, see Calibration

Manual for options available.

18 Auxiliary input 3. This is a negative switched configurable input, see Calibration

Manual for options available. It is possible to configure the input to be a normally

closed signal or a normally open signal.

19 Auxiliary input 4. As for Auxiliary input 3 (Pin 18).

20 Magnetic Input +ve. An AC signal from the magnetic pickup +ve for speed sensing.

21 Magnetic Input -ve. An AC signal from the magnetic pickup -ve for speed sensing.

22 Tachometer output +ve. 0.5 or 1.0 mA Tachometer can be used.

23 Tachometer output -ve. ---------------------- “ ----------------------------

Loading...

Loading...