ISO 9001: 2015

TCDS EASA: EASA P.038

Part 21G EASA: FR.21G.0273

17/27

TIGHTENING TORQUE

2,5 Kg/m 25 N.m

STEP 6.

Once the desired pitch angle obtained, slightly tighten the assembly screws of

the hub, those around the foot blade and then perform the same operation on

each of the other blades.

STEP 7.

Remove the adjusting tool from the propeller then perform a first tightening of the bolts manually.

Then, carry out a progressive tightening of all the screws by applying the correct torque with a torque wrench:

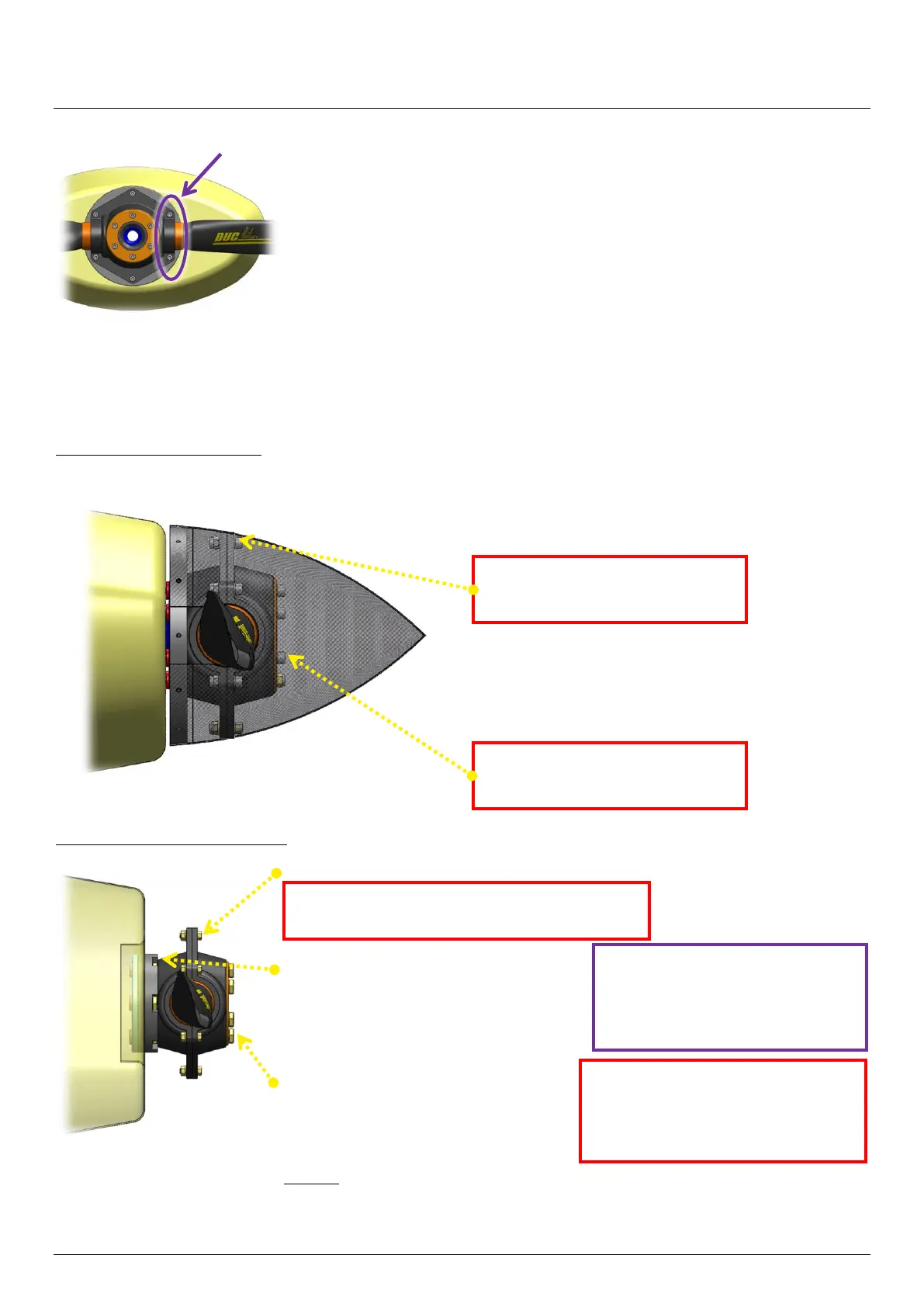

Mounting with a 912H spacer:

Assembly of the three-blade hub + Fixation of the

spacer (EI-912H-80, 100, 120):

(screw length adapted according the adaptor spacer

length and the starter flange on the propeller-shaft)

Propeller fixing: (or spacer if spacer > 80mm)

Screw CHC M8 & pin contact washer (screw length

adapted according the length of the spacer).

Use with dowel threaded on the engine propeller shaft

(Ex: For Rotax 912S, Screws CHC M8x130mm)

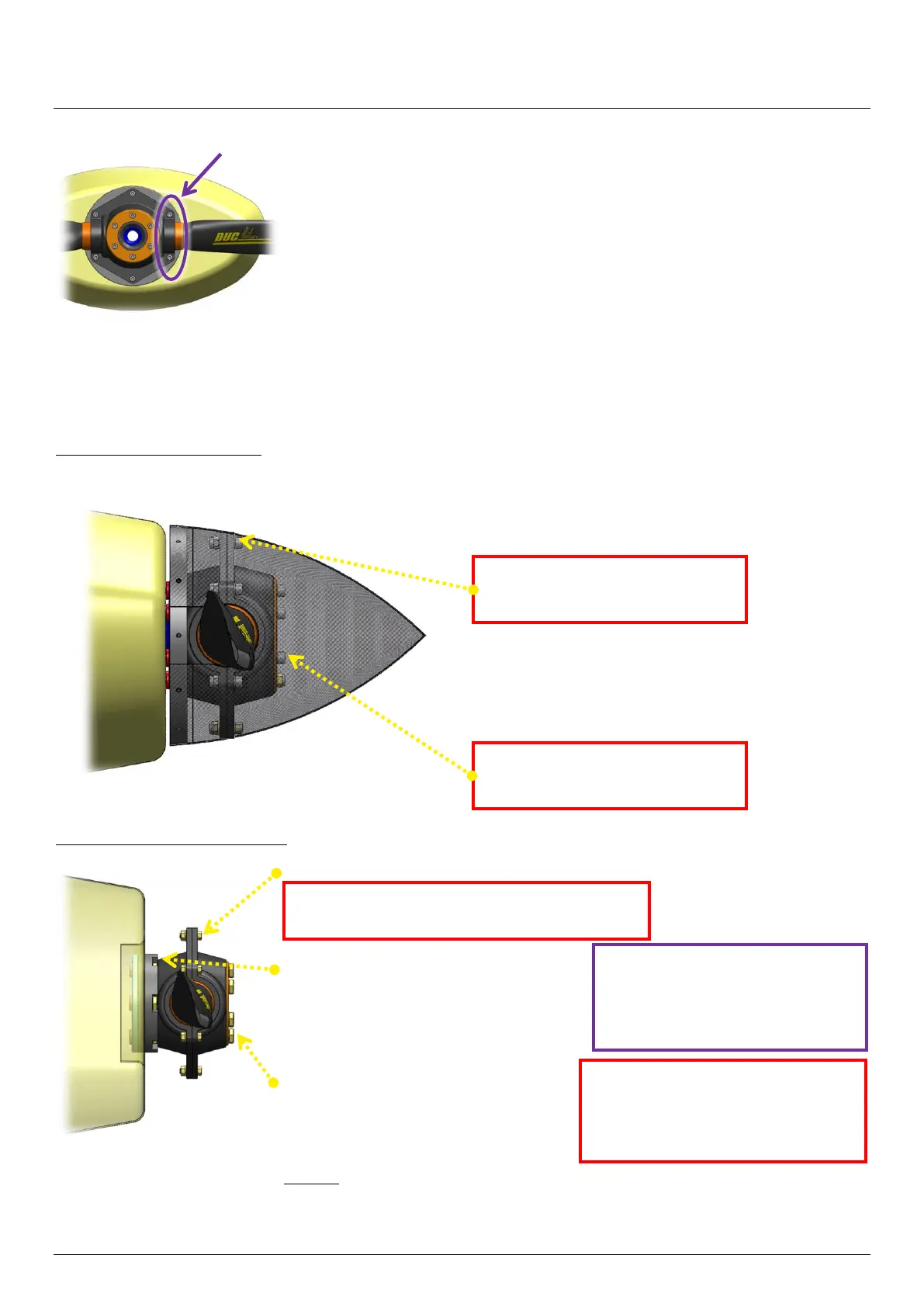

Mounting with an Adaptor spacer:

Assembly of the three-blade hub

Fixation of the Adaptor spacer:

Screws AN6 or AN8

(screw length adapted according the

adaptor spacer length and the starter

flange on the propeller-shaft)

Propeller fixing screws:

SAE1: Screws DUC AN6-52

SAE2: Screws DUC AN8-52

Remark: It is imperative to use a spinner when using propeller FLASH-R.

The mounting plate of the spinner can be placed before or after the spacer

adaptation. It is necessary to adapt the mounting in function of its position

TIGHTENING TORQUE

2,5 Kg/m 25 N.m

TIGHTENING TORQUE

2,5 Kg/m 25 N.m

TIGHTENING TORQUE

ADAPTOR SPACER

AN6 bolt (3/8"): 3.0 Kg/m 30 N.m

AN7 bolt (7/16"): 3.5 Kg/m 35 N.m

AN8 bolt (1/2"): 4,5 Kg/m 45 N.m

TIGHTENING TORQUE

PROPELLER FIXING

AN6 bolt (3/8"): 3 Kg/m 30 N.m

AN7 bolt (7/16"): 3.5 Kg/m 35 N.m

AN8 bolt (1/2"): 4,5 Kg/m 45 N.m

Loading...

Loading...