24

WARNING

Asphyxiation hazard! Improper installation could

result in death or serious injury. Read Twin

Pipe Installation Instructions completely and

understand all requirements before beginning

installation.

!

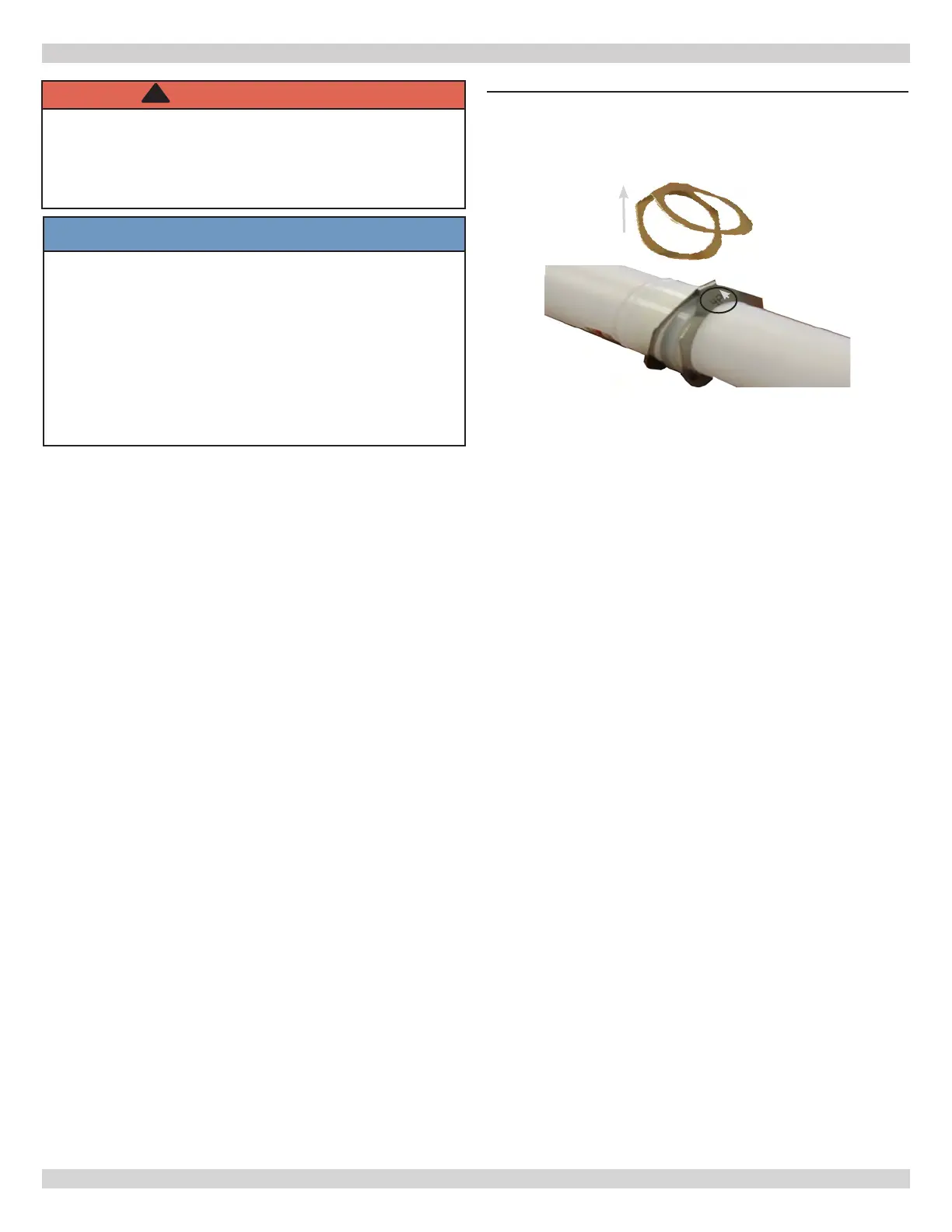

Example for Natalini venting system. See gure 5-11

(For other venting system suppliers see their

instructions.)

1.

Place clamp so etched "UP" is facing up.

2.

Open clamp slightly by separating circular areas

from each other.

3.

the shoulder of the female end of the pipe stops the

4.

Insert the male end of the second pipe into the

clamp on the "up" etched side. Force the two pipes

together.

5.

Verify the two pipes are secure together with clamp

in place.

5.9 Securing Twin Pipe Polypropylene Venting

Figure 5-11 - Natalini Clamp

UP

UP

UP

NOTICE

Venting manufacturer's use a device to secure

single wall twin pipe polypropylene vent pieces

to each other. Proper application of the securing

mechanism is necessary for any use of twin pipe

polypropylene venting on exhaust or air intake.

Securing mechanism is for indoor use only and

should not be used in outdoor applications.

Follow venting manufacturer’s instructions for

applying the securing mechanism on twin pipe

polypropylene venting.

5 - COMBUSTION AIR AND VENT PIPING

240013375 REV A, [07/01/2021]

Loading...

Loading...