20

GENERAL INSTRUCTIONS

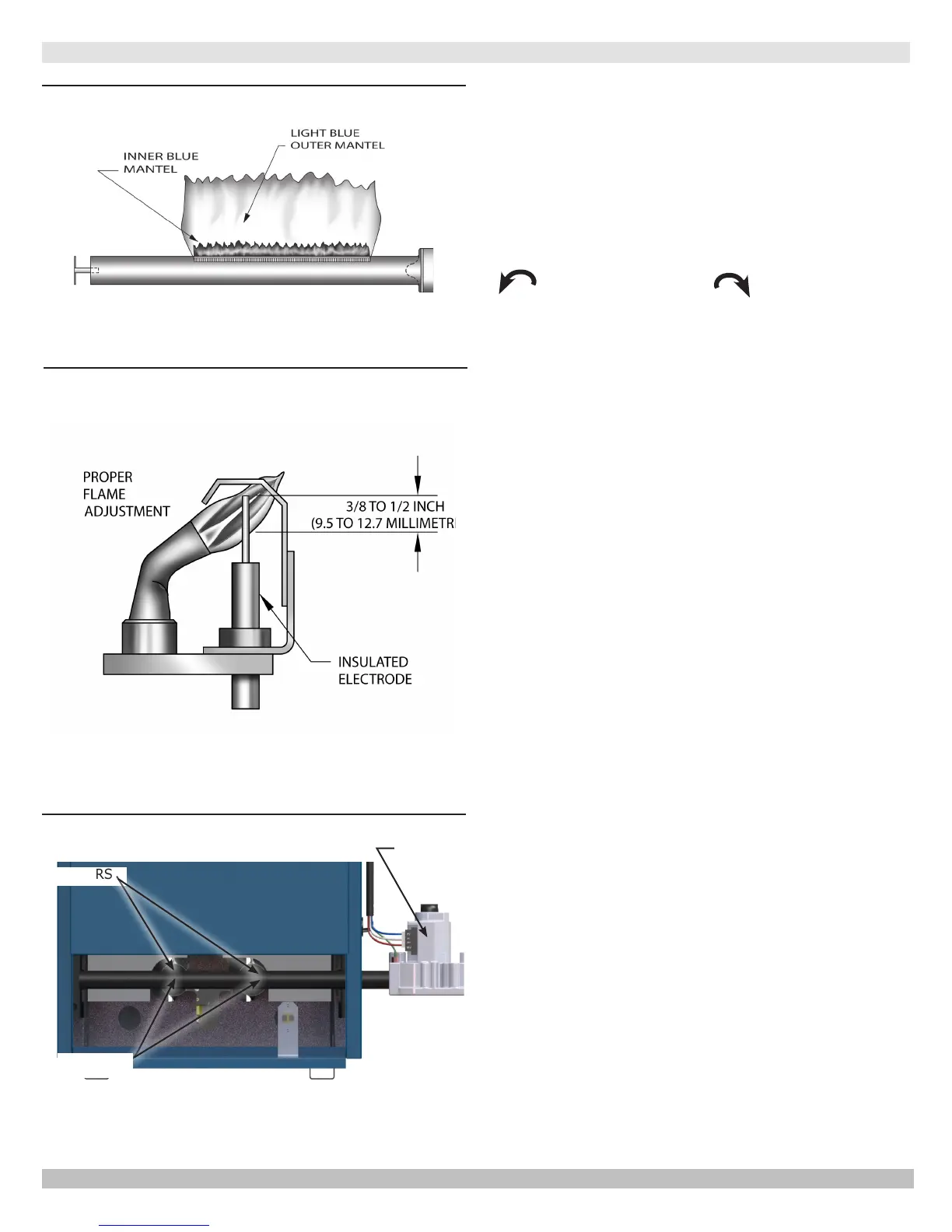

Figure 18 - Gas Burner Flame

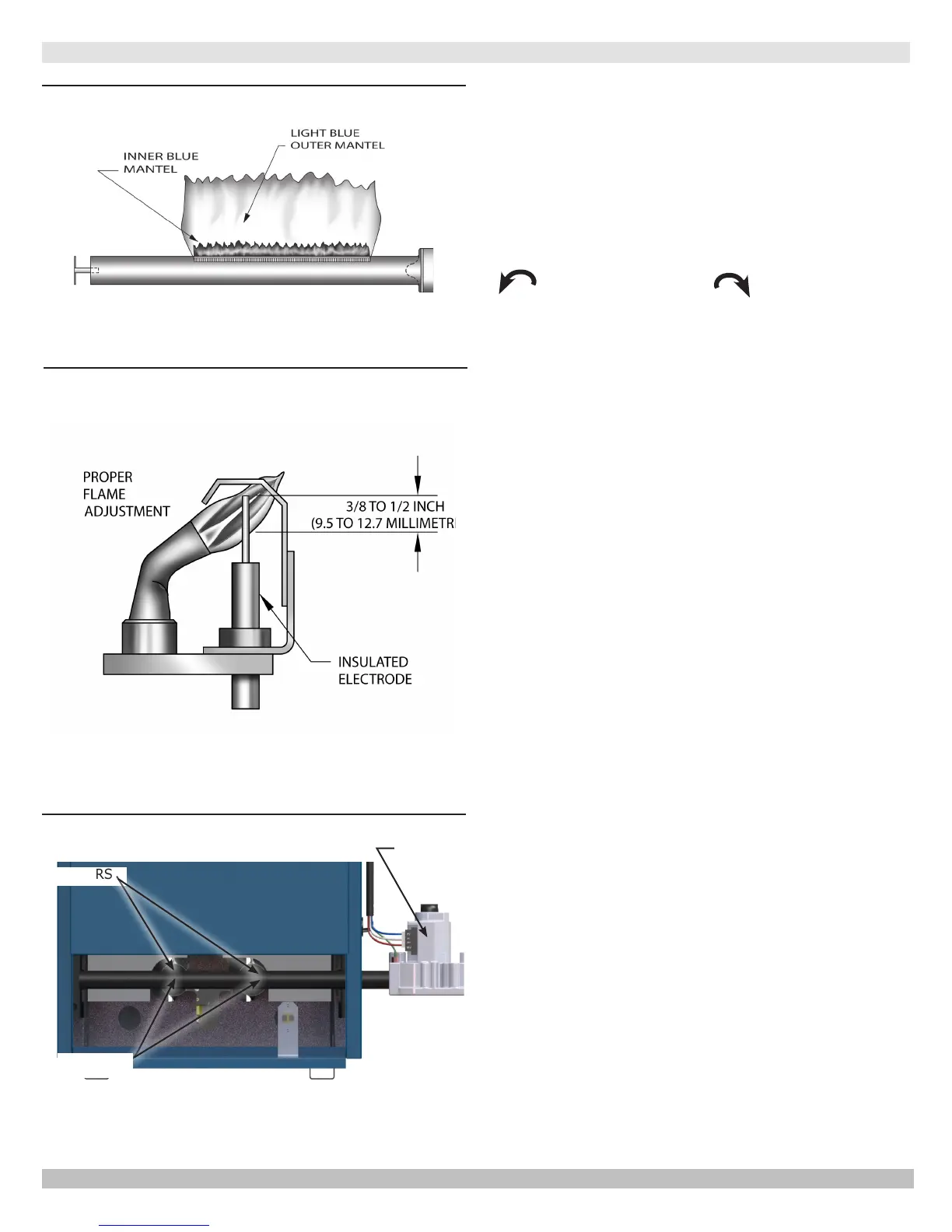

Figure 19 - Gas Burner Pilot

Figure 20 - Combustion Chamber

BURNERS

ORIFICES

GAS VALVE

• Make visual inspection of main burner and pilot ames

at start of heating season and again in mid-season. Main

burner ame should have well dened inner blue mantel

with lighter blue outer mantel. Check burner throats and

burner orices for lint or dust obstruction. Figure 17 and

18

.

• Pilot ame should envelop ⅜ to ½ inch of tip of ignition/

sensing electrode. See

Figure 19

.

• To adjust pilot ame, remove pilot adjustment cover

screw and turn inner adjustment screw counterclockwise

to increase or clockwise to decrease pilot

ame. Be sure to replace cover screw after adjustment to

prevent possible gas leakage. See Figure 16, Page 19.

• Check burners and pilot for signs of corrosion, rust or

scale buildup.

• Area around boiler must be kept clear and free of

combustible materials, gasoline and other ammable

vapors and liquids.

• Free ow of combustion and ventilating air to boiler and

boiler room must not be restricted or blocked.

• Inspect eld sourced low water cutoffs annually, or

as recommended by low water cutoff manufacturer.

Flush oat type low water cutoffs per manufacturer's

instructions.

• Employ a qualied service agency to make annual

inspection of boiler and heating system. They are

experienced in making the inspections outlined above,

and, in event repairs or corrections are necessary,

trained technicians make the proper changes for safe

operation of the boiler.

P/N 240009041, Rev. C [04/30/2017]

Loading...

Loading...