SDI-01

Feb ‘15

- 8 -

Lubrication

Each Compressor Unit built is extensively tested at the

factory before shipment. The Unit is shipped with the

original oil in it as used for testing purposes.

Check the oil level and for any oil leaks on a daily

basis. This must be done when the Unit is off. Top up

the Oil level on a monthly basis.

Use only DV Systems Premium Compressor Oil. Also,

do not mix the DV Systems oil with any other lubricant.

Oil Changes.

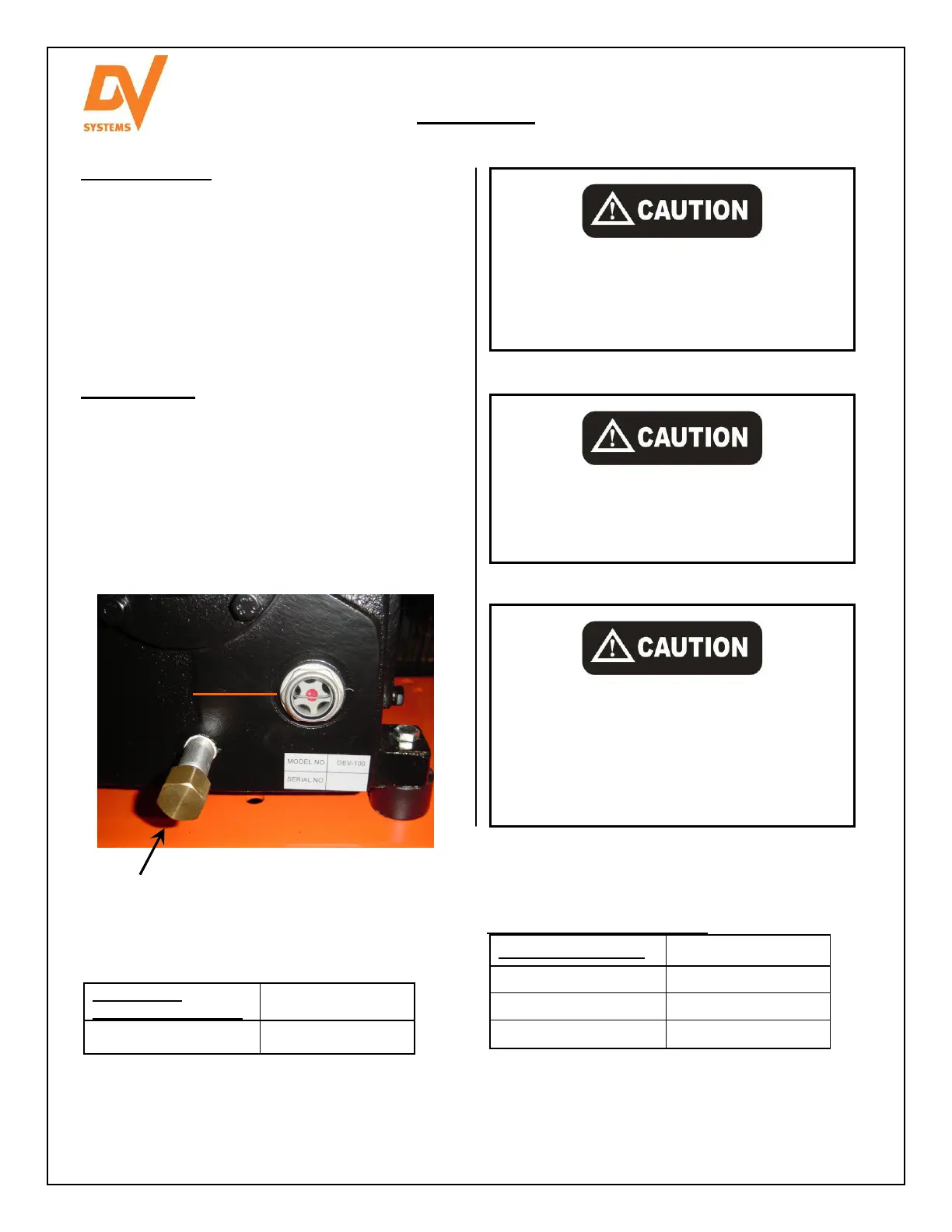

Drain the existing oil from the Unit by removing the Cap

at the Oil Drain as shown below. Running the Unit prior

to draining the oil will ensure that the oil will drain

relatively quickly.

Fill the Oil Reservoir to the center of the Oil Sight Glass

as indicated below. Do not under or overfill.

Do not attempt to operate the Unit without

first checking whether there is oil in the

Pump Crankcase. Add oil as required.

Serious damage may result from use,

however limited, without oil.

Use of improper oil may negatively affect

Compressor performance or shorten Unit life.

Resulting problems are not covered by the

DV Systems Warranty.

With limited Compressor use or installing in a

very humid environment, condensation

(water) may form in the Crankcase with the

oil. If this occurs, change the oil more often

than indicated on the Maintenance Schedule.

Also, when running the Unit, allow it to run

longer to rid the Pump of any condensation.

Oil Drain

Level

The following oil is available from your DV Systems

Distributor.

Premium Mineral Oil

Temperature

30 Weight: ‘PR-31-4’ Up to 90°F (32°C)

The following Maintenance Kits are available from

your DV Systems Distributor. The Kits include both

the Oil and Filters.

Kits c/w 30 Weight Mineral Oil

DV Systems Pumps Kit Part Number

DEV-20, 30, 30-1, 40 MK-40

DEV-55 MK-55

DEV-100 MK-100, MK-100-1*

*See page 14 to clarify Kit Part Number

Loading...

Loading...