15

CC 102/C/122/C/132/142/C O102EN3

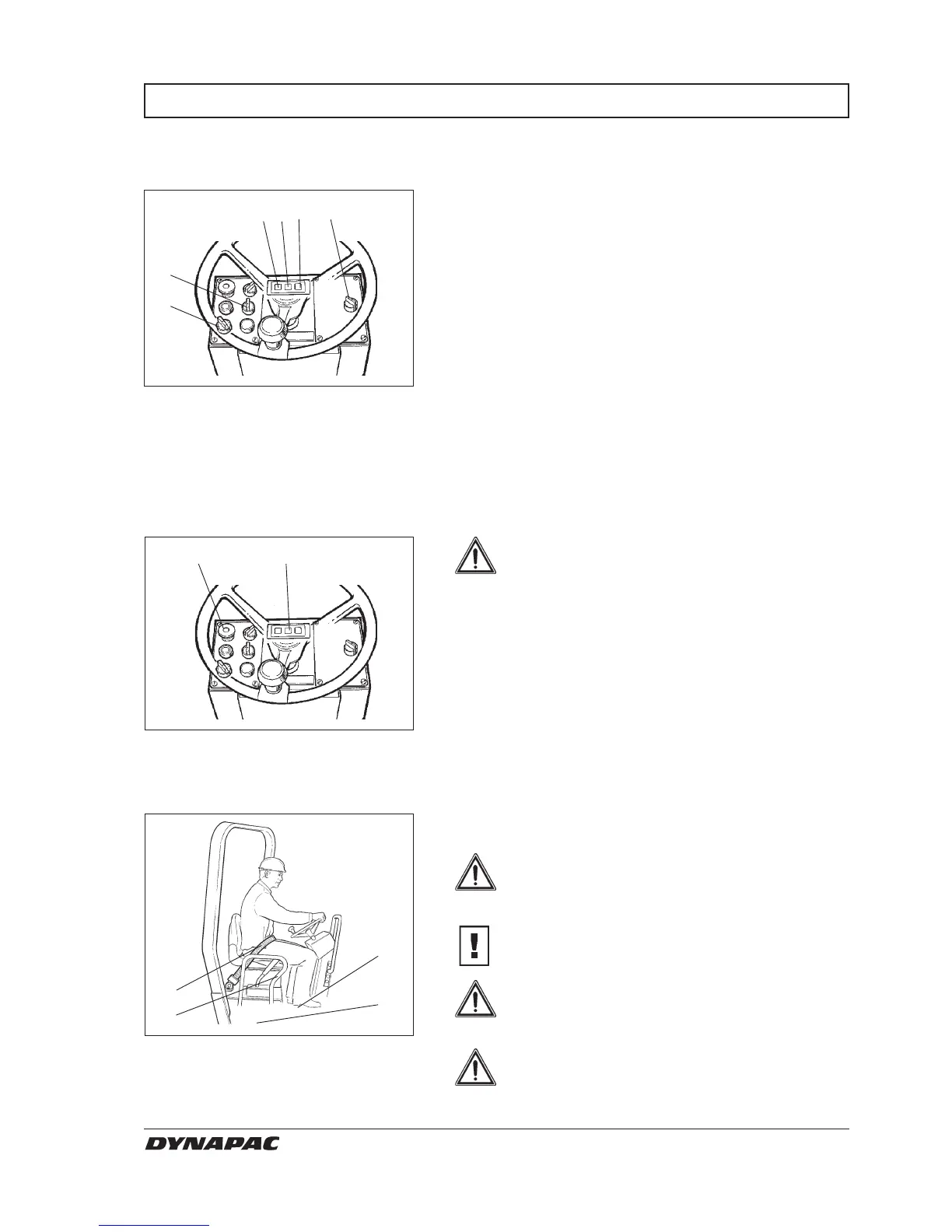

6 9

8 9 10 14

3

2

Instruments and lamps

– Check

Fig. 14 Instrument panel

2. Ignition switch

3. Sprinkler switch (drum)

8,9,10. Warning lamps

14. Sprinkler switch (rubber tires)

Turn the ignition switch (2) to the right position.

Check that the warning lamps 8, 9 and 10 light.

Turn the switches (3) and (14) for sprinklers to opera-

ting mode and make sure that the system is working.

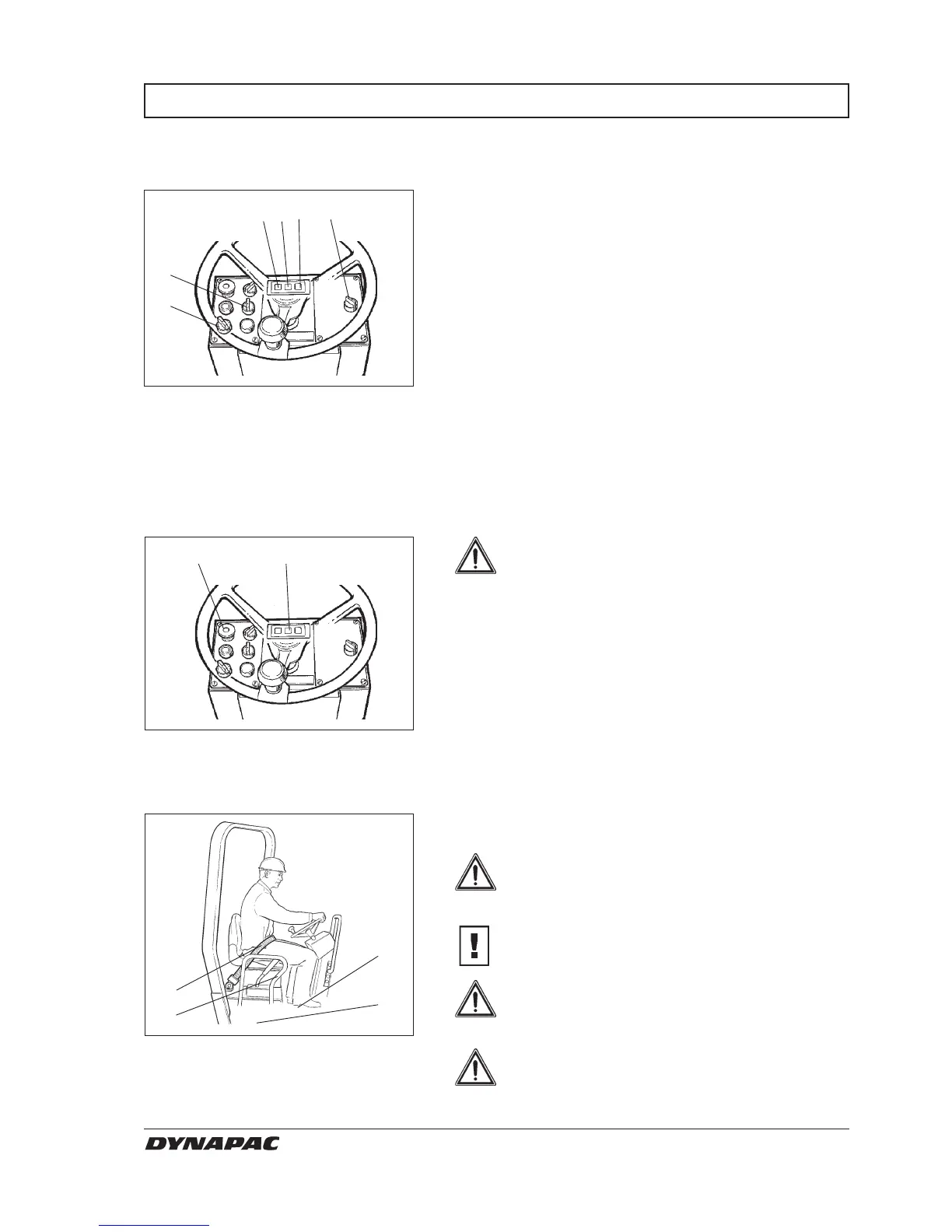

Fig. 15 Instrument panel

6. Reserve/parking brake knob

9. Brake warning lamp

Parking brake – Control

BEFORE STARTING

Make sure that the reserve/parking brake

knob (6) is pushed in. If the parking brake

is not applied, the roller may start to roll

when you start the engine on sloping

ground.

IInterlock (Optional)

The engine switches off 4 seconds after the operator

rises from the seat. This will occur regardless of

whether the forward/reverse lever is in neutral or drive

mode. The engine will not stop if the parking brake is

activated.

Always replace the seat belt (1) with a new

one if it is worn or has been subjected to a

heavy load.

Check that rubber elements (3) on the platform

are intact. Worn elements will impair comfort.

Make sure that anti-slip (4) on the platform

is in good condition; replace with new anti-

slip if friction is poor.

If the machine is fitted with a cab, make

sure that the door is closed when in mo-

tion.

Always fasten the seat belt (1) that is provided if a Roll

Over Protective Structure (ROPS) or a cab is fitted on

the roller, and wear a protective helmet.

Operator’s station

1

Fig. 16 Operator’s station

1. Seat belt

2. Safety railing

3. Rubber element

4. Anti-slip

2

3

4

Loading...

Loading...