Roller prepared for

transportation

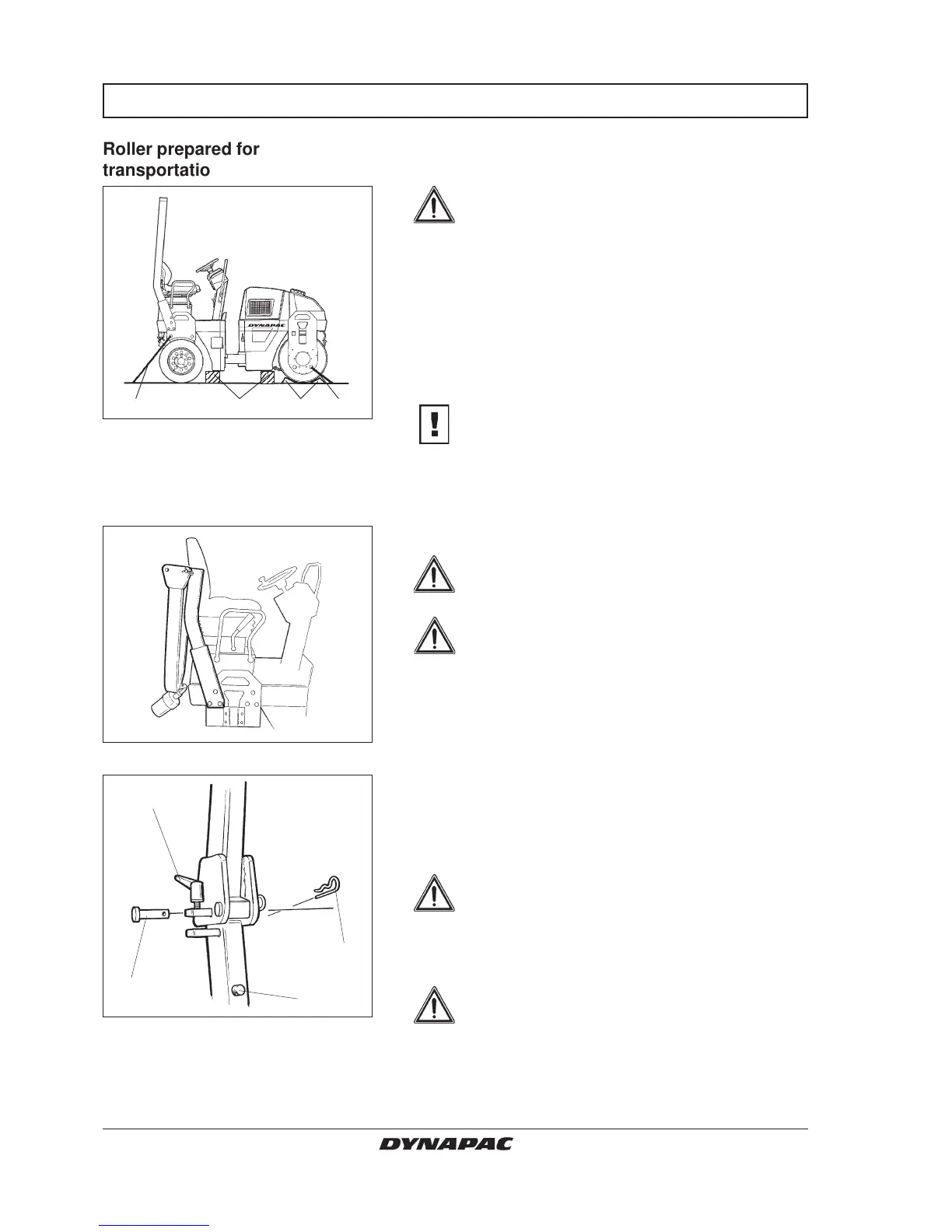

Fig. 39 Transporting a roller

1. Chock

2. Block up

3. Lashing wire

TRANSPORTATION

Interlock the articulation before hoisting

and transportation; follow the instructions

under the respective heading.

Chock the drums (1) and secure the chocks to the

transport vehicle.

Block up under the drum frame (2), to avoid overload

on the rubber suspension of the drum when lashing.

Clamp down the roller with lashing straps (3) at all four

corners; decals indicate the fixing points.

Remember to restore the articulation interlock

to open mode before starting the roller again.

Retractable ROPS (Optional)

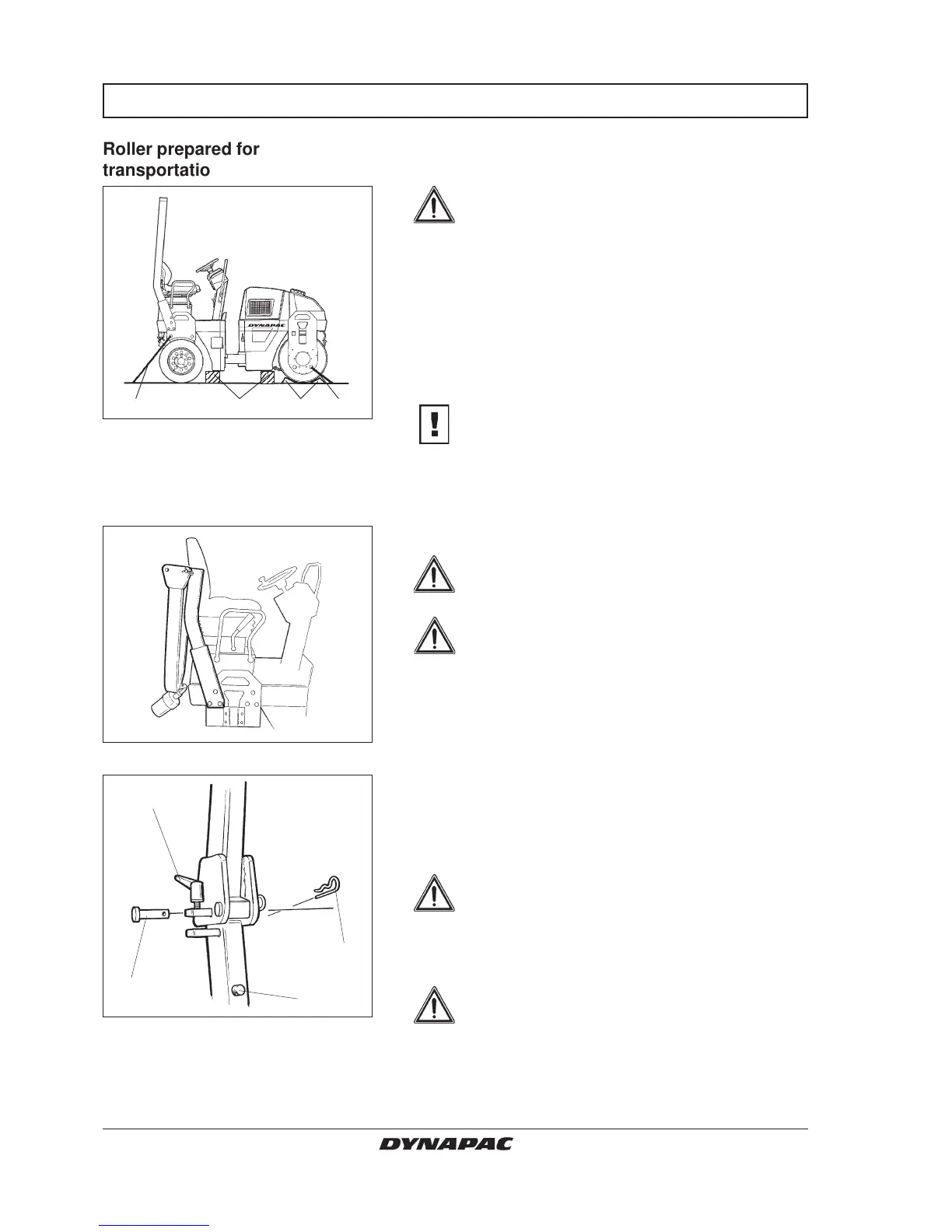

Fig. 40 Retractable ROPS

The machine can be fitted with retractable ROPS.

Risk of being crushed when raising and

lowering the exhaust pipe.

If the roller is equipped with a retractable

protective structure, ROPS, then the mach-

ine may only be operated with the structu-

re raised and locked in position.

To retract the protective structure, unscrew the securing

screw (1), pull out the cotter pin (2) and pull out the bolt

(3). Do this on both sides of the structure. If there is

sufficient space the structure should preferably be

retracted to the rear.

Restore the cotter pins and the bolts into

position after retracting the structure.

Proceed in the reverse order to the above when raising

the structure.

Always ensure that the structure is locked

in its raised position before driving the

roller.

Lubricate the securing screw (1) and the bolt (3)

occasionally with waterproof grease.

Fig. 41 Locking the protective structure

1. Securing screw

2. Cotter pin

3. Bolt

4. Rubber buffer

1

2

3

4

Loading...

Loading...