14 CC102/C/122/C/132/142/C M102EN4

Make sure that the scrapers are undamaged. The

spring-action scrapers require no adjustment because

the spring force provides the correct contact force.

Asphalt remnants can accumulate on the scraper and

influence the contact force. Clean as necessary.

Make sure the scrapers are retracted from the

drum during transport driving.

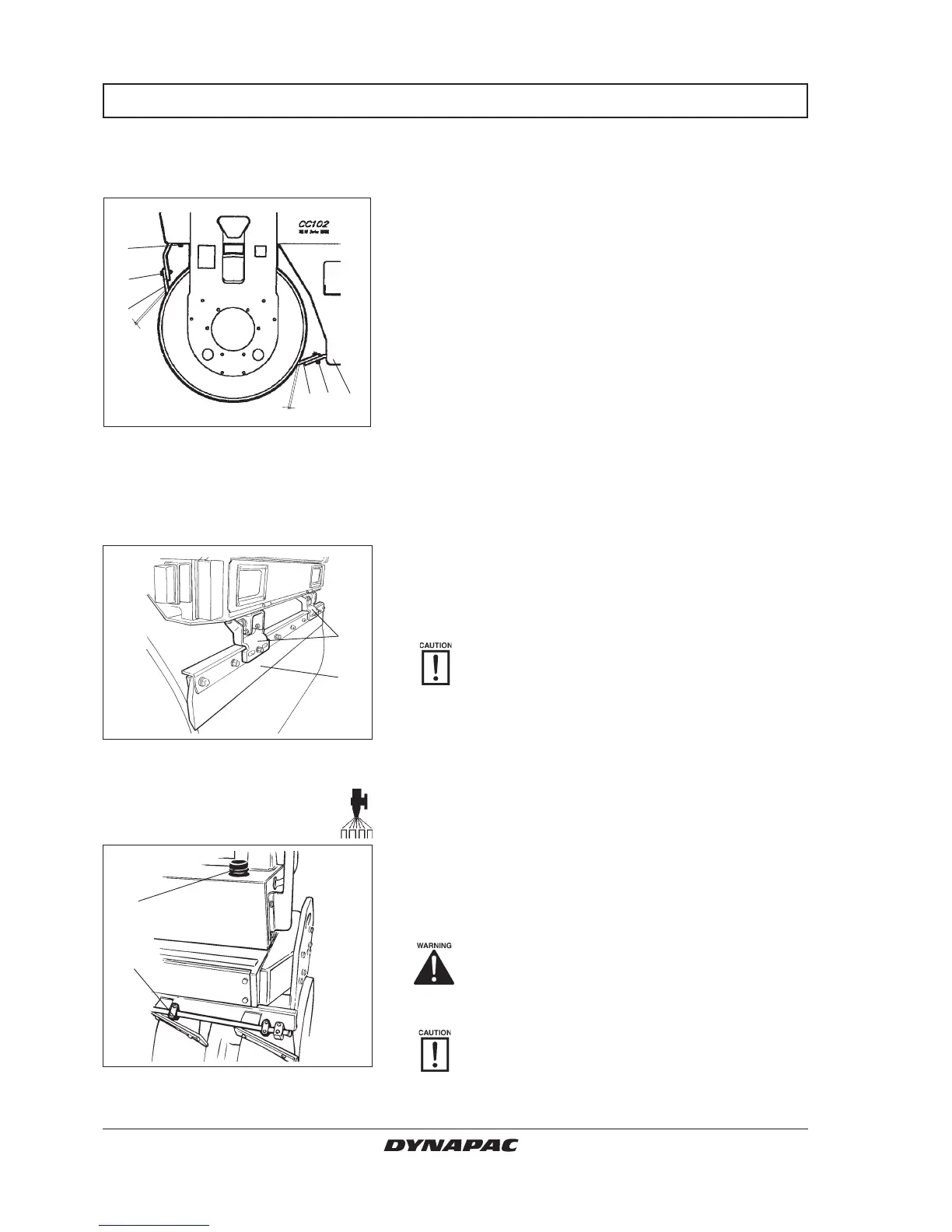

Fill the rear tank with emulsion fluid, for example water

mixed with 2% cutting fluid. Make sure that the sprink-

ler nozzles (2) are not clogged. Clean them and the

filter if necessary. See under Sprinkler system/Drum;

Check—Cleaning, for detailed instructions.

Fluids that are flammable or harmful to the

environment may not be used in the emul-

sion tank.

Inspect the tire tread now and then to detect

asphalt compound that has fastened; this is

likely until the tires are warm enough.

Sprinkler system/Wheels

Checking—Cleaning

Fig. 13 Wheel rack

1. Filler cap

2. Nozzle (one for each tire)

1

2

EVERY 10 HOURS OF OPERATION (Daily)

Scrapers, spring-action

(Optional) – Check

Fig. 12 Spring-action scrapers

1. Spring mechanism

2. Scraper blade

1

2

Fig. 11 Drum

1. Scraper blade

2. Adjusting screws

3. Adjusting screws

1 2 3

3

2

1

Make sure that the scrapers are undamaged. Adjust

the scrapers so that they lie 1–2 mm from the drum. For

special asphalt compounds it may be better if the

scraper blades (1) lie lightly against the drums.

The remains of asphalt can accumulate on the scraper

and thus influence the contact force.

Loosen the screws (2) to adjust the scraper blade up or

down.

Loosen the screws (3) to adjust contact pressure of the

scraper blade against the drum.

Remember to tighten all the screws after any

adjustment.

Scrapers, fixed

Checking – Setting

1-2 mm

1-2 mm

Loading...

Loading...