For more information visit: www.eaton.com IB01602008E

Instructional Booklet

Page 32 Effective: March 2014

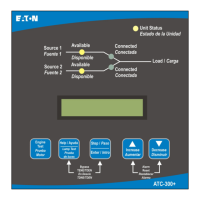

ATC-300 Breaker Based Transfer Switch

Step 3: With the emergency generator in the OFF position, close

the Source 2 power source upstream protective device,

assuming such a device used.

Step 4: Close any generator engine-start controls opened as a

result of actions taken in Step 4, Section 6.1.2.

Step 5: Where required, use an accurate voltmeter to check

phase-to-phase and phase-to-neutral voltages present at

the transfer switch Source 1, Source 2, and/or load termi-

nals.

6.1.4 Operational Checks

Step 1: Check to ensure that the Source 1 switching device is in

the CLOSED position. This should have been done in Sec-

tion 6.1.3, Step 1.

Step 2: Initiate an automatic transfer operation from the Source 1

to the Source 2 power source by pressing the <Engine

Test> pushbutton two times.

Note:The ATC-300 Logic Controller provides the capability to set the

Engine Test function to:

1. No Load Engine Test;

2. Load Engine Test; or

3. Disabled.

The factory default is set to:

1. Load Engine Test

a. After the Time Delay Engine Starting (TDES) has timed out,

the engine should start, run, and build up to normal voltage

and frequency.

b. The transfer switch will transfer to the Source 2 power

source (the Source 1 switching device opens and Source 2

switching device closes) after the Time Delay Normal to

Emergency (TDNE) times out.

Step 3: Initiate an automatic transfer operation back to the Source

1 power source by pressing the <Engine Test> pushbut-

ton one time.

1. After the Time Delay Emergency to Normal timer (TDEN)

has timed out, the transfer switch will transfer back to

the Source 1 power source (the Source 2 switching

device opens and the Source 1 switching device closes).

2. The Time Delay for Engine Cool-Off (TDEC - Feature 4)

will allow the engine to run unloaded for a preset time

after transfer to the Source 1 power source is com-

pleted.

6.1.5 Alternate Tests

1. Alternate operational tests may be possible depending upon

the options provided with any given ATS. Refer to the sche-

matic diagram provided with the ATS equipment, along with

the specification nameplate, to determine the exact options

provided.

2. If you attempt to manually operate the ATS with the Source 1

power source connected and available, the ATC-300 logic will

cycle the ATS back to the Source 1 power source since it is

the preferred source. The ATS was designed with this safety

feature in case a manual transfer is attempted while the

switch is in automatic mode and under load.

6.2 Problem Solving

HAZARDOUS VOLTAGES IN AND AROUND ATS EQUIPMENT DURING

THE PROBLEM SOLVING PROCESS CAN CAUSE SEVERE PERSONAL

INJURY AND/OR DEATH. AVOID CONTACT WITH ANY VOLTAGE

SOURCE WHILE PROBLEM SOLVING.

ONLY PROPERLY TRAINED PERSONNEL, FAMILIAR WITH THE ATS

EQUIPMENT AND ITS ASSOCIATED EQUIPMENT, SHOULD BE PERMIT-

TED TO PERFORM THE PROBLEM SOLVING FUNCTION. IF AN INDI-

VIDUAL IS NOT QUALIFIED TO PERFORM THE PROBLEM SOLVING

FUNCTION, THE INDIVIDUAL SHOULD NOT ATTEMPT ANY OF THESE

PROCEDURES.

A basic problem-solving effort is the first step to take prior to call-

ing for assistance. Frequently, the effort will successfully address

most problems encountered. The problem solving procedure is

presented in the Troubleshooting Guide (Table 3, Section 7 of

ATC-300 Controller Instruction Booklet IB01602009E). Remem-

ber, only qualified individuals familiar with the ATS equipment and

the system in which it is applied should attempt these problem

solving procedures.

If a problem persists after having completed the problem solving

procedure, contact a Eaton representative for further assistance.

When calling for assistance, the following is the minimum informa-

tion required to properly address the need:

1. Style number of ATS, if applicable;

2. Catalog number of ATS;

3. Actual location of the ATS (type of facility, address, etc.);

4. Company name and name and position of individual represent-

ing company;

5. Basic description of the situation as it exists; and

6. Any results of the problem solving steps taken and/or read-

ings taken.

NOTICE

AT THIS POINT, AND PRIOR TO MAKING ANY ATTEMPT TO ENER-

GIZE THE ATS EQUIPMENT, THE ENGINE-DRIVEN GENERATOR

SHOULD BE OPERATED. IF NECESSARY, THE VOLTAGE REGULA-

TOR ON THE GENERATOR SHOULD BE ADJUSTED ACCORDING TO

THE MANUFACTURER’S RECOMMENDATIONS. THE ATS EQUIP-

MENT WILL RESPOND ONLY TO THE RATED VOLTAGE AND FRE-

QUENCY PROGRAMMED INTO THE CONTROLLER.

WARNING

WARNING

Loading...

Loading...