IB01602008E For more information visit: www.eaton.com

Instructional Booklet

Effective: March 2014 Page 31

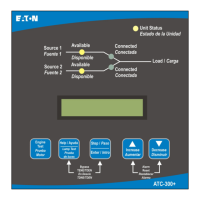

ATC-300 Breaker Based Transfer Switch

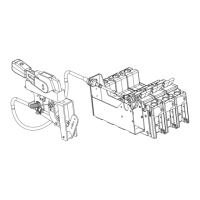

Figure 35.Switch Being Manually Operated (30-150 A Model).

5.4 Automatic Transfer

The operating sequence of an ATS is dictated by the switch's

standard features and selected options. Operation of an ATS dur-

ing Source 1 power source failure and Source 1 power source res-

toration will be described here with only standard options included

on the switch. Additional options, as described in Section 3, can

change sequences and timing, depending upon the options

selected. It is strongly suggested that you become familiar with

additional options selected with the particular ATS and their effect

on the normal operation of an ATS.

5.4.1 Source 1 Power Source Failure

Standard Source 1 power source failure is defined as a reduction

or loss of voltage. If this occurs, the sequence of operation is as

follows.

1. Failure of Source 1 is detected by the controller intelligence.

2. When the controller detects a failure, the engine contacts

close (after delay if programmed) and start the engine-driven

generator.

3. When the Source 2 voltage reaches its operation rating, the

K2 relay closes, starting the transfer operation. This operat-

ing sequence opens the Source 1 switch and closes the

Source 2 switch.

4. The load is now transferred to the Source 2 power source.

5.4.2 Source 1 Power Source Restoration

1. A return to the Source 1 power source begins when the volt-

age in all phases of a three-phase sensing unit, or phase-to-

phase in a single sensing unit, is restored to a preset value.

2. At the present voltage, the controller will cause the K1 relay

to change state. This starts the return to the Source 1 power

source and Source 1 transfer switch operation.

3. During this sequence, the Source 2 power source switch is

opened and the Source 1 power source switch is closed.

4. Simultaneously, the engine cool-down timer initiates the shut

down of the engine driven generator.

5. Transfer of the load back to the Source 1 power source is

now complete.

Section 6: Testing and Problem Solving

6.1 Testing

After the ATS equipment is initially installed or during planned out-

ages, the installation should be tested to ensure that all equipment

operates properly. This attention to detail will help avoid unex-

pected malfunctions. Mechanical and/or electrical tests should be

performed as described in this section.

The frequency of subsequent testing should be based on recom-

mendations of the Genset manufacturer. Use the test pushbutton

to check the electrical operation of the switch.

6.1.1 Mechanical and/or Electrical Testing

SINCE FEATURE 4 (TIME DELAY ENGINE COOL-OFF), AS DESCRIBED

IN SECTION 3, IS A STANDARD FEATURE, AN ENGINE START SIGNAL

WILL BE PRESENT FOR A PERIOD OF TIME WHEN THE SWITCH IS

FIRST ENERGIZED. THE PERIOD OF TIME IS EQUAL TO THE TIMER

SETTING. TO AVOID STARTING THE ENGINE DURING THIS TIME

PERIOD, TURN THE GENERATOR CONTROLS TO THE OFF POSITION.

Energize the ATS equipment as described in Sections 6.1.2

through 6.1.6. Insure that all safety precautions are taken and

that all WARNINGS and CAUTIONS are observed.

6.1.2 No Voltage Steps

With no voltage available on either power source, proceed as fol-

lows.

Step 1: Check to make sure that both the Source 1 and Source 2

power switching devices are in the OPEN position. The

switching devices can be put into the OPEN position

using of the manual operating handle, stopping in the

NEUTRAL position.

Step 2: The generator engine start controls should be in the OFF

position to prevent an undesired start.

Step 3: Ensure that the ATS has been set to the proper applied

system voltage (See Section 4.8).

Step 4: Check all ATS loads to ensure that they are ready to be

energized.

6.1.3 Connecting the Power Sources

Step 1: Close the Source 1 power source upstream protection

device. The Source 1 power switching device should

close

Step 2: Connect the engine start battery cable.

WARNING

HIGH VOLTAGES ASSOCIATED WITH OPERATIONAL TRANSFER

SWITCH EQUIPMENT PRESENT A SHOCK HAZARD THAT CAN

CAUSE SEVERE PERSONAL INJURY OR DEATH. USE EXTREME CAU-

TION TO AVOID TOUCHING ELECTRICAL CONNECTIONS WHENEVER

INSPECTING OR TESTING THE EQUIPMENT.

IN ADDITION, IMPROPER OPERATION OF THE GENERATOR SET

PRESENTS A HAZARD THAT CAN CAUSE SEVERE PERSONAL

INJURY OR DEATH. OBSERVE ALL SAFETY PRECAUTIONS IN YOUR

GENERATOR SET OPERATIONS AND INSTALLATION MANUALS.

NOTICE

Loading...

Loading...