IB01602008E For more information visit: www.eaton.com

Instructional Booklet

Effective: March 2014 Page 19

ATC-300 Breaker Based Transfer Switch

Section 4: Installation and Wiring

4.1 General

Eaton ATSs are factory wired and tested. Installation requires sol-

idly mounting the enclosed unit and connecting power cables and

auxiliary pilot circuits. Physical mounting procedures and power

cable connections are covered in this section. All other required

wiring or electrical connection references are covered in a sepa-

rate Customer Wiring Booklet packaged with the ATS.

Locate the wiring schematic, review it, and keep it readily avail-

able for reference purposes during installation and testing. Once

an ATS is properly installed and wired, it should be mechanically

and electrically checked for proper installation and operation. The

procedures for these initial mechanical and electrical checks are

outlined in Section 6 of this instruction manual.

TO FACILITATE THE PROCEDURES DESCRIBED IN THIS SECTION, THE

SOLID STEEL SHIELD OVER THE POWER PANEL SHOULD BE

REMOVED. THE SHIELD IS ATTACHED TO THE RATCHET ASSEMBLY

WITH FOUR SCREWS. REMOVE THE FOUR SCREWS AND SHIELD

UNTIL THE PROCEDURES ARE COMPLETED.

BE CERTAIN THAT THE SOLID STEEL POWER PANEL SHIELD IS PROP-

ERLY INSTALLED BEFORE THE TRANSFER SWITCH EQUIPMENT IS

PUT INTO SERVICE. THE SHIELD PROVIDES PROTECTION FROM DAN-

GEROUS VOLTAGES AT THE LINE AND LOAD TERMINALS WHEN THE

EQUIPMENT IS IN OPERATION. FAILURE TO DO SO COULD RESULT IN

PERSONAL INJURY OR DEATH.

4.2 Mounting Location

Choose a location that offers a flat, rigid mounting surface capa-

ble of supporting the weight of the enclosed ATS equipment. For

standard ATSs, avoid locations that are moist, hot, or dusty.

However, Eaton offers optional enclosure designs that can be

used in special environments. If there are any doubts as to a loca-

tion’s suitability, discuss them with your Eaton representative.

Check to make certain that there are no pipes, wires, or other

mounting hazards in the immediate mounting area that could cre-

ate a problem.

Carefully remove all packing material from the ATS at the mount-

ing location. Even though an equipment inspection should have

been made when the equipment was received, make another care-

ful inspection of the enclosure and the enclosed ATS components

as the packing material is removed and the enclosure readied for

mounting. Be especially alert for distorted metal, loose wires, or

damaged components.

4.3 Mounting Procedure

SINCE THE ENCLOSED ATS MUST BE LIFTED INTO PLACE FOR

MOUNTING, BE CERTAIN THAT ADEQUATE RESOURCES ARE AVAIL-

ABLE FOR LIFTING TO AVOID PERSONNEL INJURIES OR EQUIPMENT

DAMAGE.

All vertical design ATS equipment enclosures and power panels

are of the same design. Only the overall physical dimensions

change. Note that the enclosure is provided with four teardrop

(elongated) mounting holes, two in the top mounting flange and

two in the bottom. Also notice that the power panel has two sets

of mounting holes. One set positions the power panel for top

entry of cables and one set for bottom entry. This will be covered

in more detail in Section 4.4.

Eaton ATS equipment is assembled and supplied as standard for

top entry (see Figure 17), although equally adaptable to bottom

entry. Cable entry holes are not part of the enclosure when

shipped from the factory and must be provided in the field, either

before or after mounting the enclosure.

EXTREME CARE SHOULD BE TAKEN TO PROTECT THE TRANSFER

SWITCH FROM DRILL CHIPS, FILINGS, AND OTHER CONTAMINANTS

WHEN MAKING THE CABLE ENTRY HOLES. EXTREME CARE SHOULD

ALSO BE TAKEN WHEN MOUNTING THE ENCLOSURE TO PREVENT

COMPONENT DAMAGE OR A FUTURE MALFUNCTION.

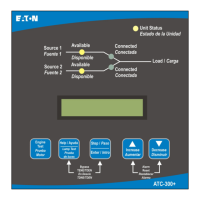

Figure 17.Typical (30-150 A) Horizontal Design ATS Equipment

(Door Open).

NOTICE

WARNING

CAUTION

CAUTION

Loading...

Loading...