Do you have a question about the ebm-papst K3G250-RR01-H8 and is the answer not in the manual?

This document outlines the operating instructions for a built-in device designed for conveying air. It emphasizes safety regulations, proper usage, and maintenance procedures to ensure safe and efficient operation.

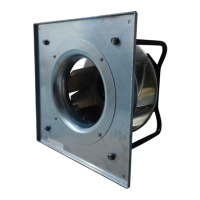

The device is primarily intended as a built-in component for air conveyance, adhering strictly to its technical specifications. It is designed for use in power systems with grounded neutral (TN/TT), phase conductor grounding, or IT power systems, and is suitable for stationary applications only. The device operates by moving air within an ambient air pressure range of 800 mbar to 1050 mbar and within a specified ambient temperature range. It incorporates an integrated PID controller, power limiter, motor current limitation, active PFC, RS-485 MODBUS-RTU, and a soft start function. Control input is managed via 0-10 VDC or PWM, with an interface that is safely disconnected from the mains by SELV potential. The device also includes thermal overload protection for both electronics and the motor, as well as line undervoltage and phase failure detection. Its protective features ensure automatic shutdown in case of rotor position detection errors, blocked rotor, or line undervoltage.

The device is designed for continuous operation (S1 mode) and features a ball bearing for smooth performance. It offers an output of 10 VDC, with a maximum current of 10 mA. Operational status and alarms are indicated by an LED display. The installation position can be with the shaft horizontal or the rotor on top, with an option for the rotor on the bottom upon request. Condensation drainage holes are located on the rotor side. The device is a built-in component and requires proper safeguarding, such as a fixed protective device and guard grill, to prevent accidental contact with rotating parts. It is crucial to ensure that the device is adequately protected against electromagnetic radiation, and if impermissible levels occur, appropriate shielding measures must be implemented by the user. The device should be secured against accidental contact and all parts must come to a standstill before any work is performed on the system or machine. The device's electrical equipment should be checked regularly, and loose connections or defective cables must be replaced immediately. When working on an electrically charged device, standing on a rubber mat is recommended to mitigate the risk of electric shock.

Regular maintenance is crucial for ensuring a long service life and trouble-free operation. This includes periodic checks for proper operation and soiling, with the frequency adjusted based on the degree of contamination. Cleaning should only be performed when the device is not in motion, and it should be switched off via the control input to prevent accidental start-up. Dry cleaning, such as using compressed air, is the preferred method. Aggressive cleaning agents should be avoided, and any cleaning agents used must be completely removed. If severe corrosion is observed on load-bearing or rotating parts, the device must be switched off immediately and replaced. Repair of load-bearing or rotating parts is not permitted. After cleaning, the fan should be operated at maximum speed for two hours to evaporate any ingressed water. If cleaning does not eliminate vibrations, rebalancing may be necessary. The fan is equipped with maintenance-free ball bearings designed for a service life of 40,000 hours. If bearing replacement is required after this period, ebm-papst should be contacted. Maintenance intervals should be adapted to the actual level of dust exposure.

A safety inspection should be conducted regularly, including visual inspections of the contact protection cover for intactness or damage, the device for damage to blades and housing, the fastening of cables, and the fastening of the protective earth terminal. These inspections should be performed at least every six months. Any damaged or loose components should be repaired, replaced, or fastened as necessary. For high-voltage testing, the device should be tested with DC voltage, as the integrated EMC filter's Y capacitors can cause the tripping current to be exceeded with AC testing voltage. The DC voltage used should correspond to the peak value of the AC voltage required by the standard. In the event of malfunctions, the device should not be repaired by the user but sent to ebm-papst for repair or replacement. If the device is not operated for a lengthy period, it should be started up and operated at full speed for at least one hour every four months in a dry environment, or once a month for at least two hours in a damp environment to move the bearings and evaporate any condensate.

| Manufacturer | ebm-papst |

|---|---|

| Model | K3G250-RR01-H8 |

| Category | Fan |

| Type | Axial fan |

| Impeller material | Plastic |

| Housing material | Plastic |

| Nominal voltage | 230 V |

| Frequency | 50/60 Hz |

| Input power | 25 W |

| Current consumption | 0.11 A |

| Speed | 3000 rpm |

| Air flow | 250 m³/h |

| Min. ambient temperature | -25 °C |

| Max. ambient temperature | 60 °C |

| Weight | 1.5 kg |

| Voltage | 230 V |

| Power | 25 W |

| Current | 0.11 A |

| Protection Class | IP54 |

| Phase | 1~ |

Loading...

Loading...