Do you have a question about the ebm-papst K3G560-PC04-01 and is the answer not in the manual?

Explains hazard level symbols and their meanings to indicate potentially hazardous situations.

Specifies that the device must only be handled by suitably qualified and trained technical staff.

Outlines fundamental safety practices for working with the device and observing local regulations.

Highlights electrical hazards, specifically warning about dangers related to voltage.

Details essential safety features and protective measures, including guards and interlocks.

Addresses potential electromagnetic interference and necessary shielding measures.

Warns about hazards related to rotating parts, contact risks, and moving components.

Discusses potential noise emissions and the need for hearing protection.

Warns about hot surfaces on the device and the risk of burns.

Provides guidelines for safely transporting the fan, including handling and securing.

Gives instructions for proper storage conditions to maintain product integrity.

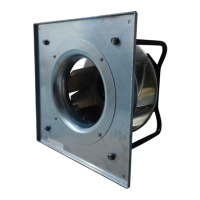

Illustrates the physical dimensions, components, and mounting points of the product.

Lists key technical specifications, performance data, and operating parameters of the motor.

Provides energy efficiency data and categories as per EU regulation.

Details the product's construction, materials, protection classes, and electrical features.

Specifies screw strength, tightening torque, and general mounting considerations.

Lists permitted ambient temperatures for transport, storage, and EMC compatibility.

Outlines EMC immunity standards and emission requirements for different environments.

Details precautions and steps for physically connecting the device, including unpacking and handling.

Covers the procedures, requirements, and safety precautions for electrical hookup.

Details preparation, cable routing, and wiring connections within the terminal box.

Lists default parameter settings configured by the manufacturer for various modes.

Presents a detailed diagram for electrical connections, terminal assignments, and circuit configurations.

Details steps to verify the correctness, security, and proper sealing of electrical connections.

Outlines prerequisites, safety checks, and steps for safe device startup.

Explains procedures for switching the device off for operation, maintenance, and disconnection.

Recommends vibration testing frequency and measurement standards for fan condition.

Provides instructions and precautions for cleaning the fan to ensure service life.

Lists checks for safety, including visual inspections and high-voltage testing procedures.

Offers recommendations for environmentally sound disposal of the product and its components.

This document provides comprehensive operating instructions for the K3G560-PC04-01 device, a built-in fan designed for conveying air. It covers safety regulations, technical data, connection and startup procedures, integrated protective features, and maintenance guidelines.

The K3G560-PC04-01 is an external rotor motor fan, primarily designed for air conveyance. It operates within a specified range of ambient air pressure and temperature, ensuring efficient air movement in various applications. The device incorporates an integrated EMC filter for compliance with electromagnetic compatibility limits. It features a robust design with components made from sheet steel, galvanized steel, painted black steel, die-cast aluminum, and sheet aluminum, ensuring durability and performance. The fan's motor is equipped with ball bearings for smooth operation and includes various protective features to ensure safe and reliable performance.

The fan's control system allows for adjustable speed settings, with options for PWM control and analog input for set value requirements. It also includes digital inputs for enabling electronics, switching parameter sets, and controlling the direction of action of the integrated controller. An analog output provides the current motor modulation level. The device is designed for use in power systems with grounded neutral (TN/TT power systems) and in networks with specific quality characteristics.

The K3G560-PC04-01 is intended for stationary systems and requires all maintenance work to be performed as specified. It is crucial to operate the device with all protective devices in place and to follow the operating instructions diligently. The fan is designed to convey air at ambient air pressures between 800 mbar and 1050 mbar and within its permitted ambient temperature range.

The device offers flexible control options, including a 0-10 VDC / PWM control input and an RS-485 MODBUS-RTU interface. It provides various outputs, such as 10 VDC and 20 VDC, for external devices and a 0-10 V output for slave control. Input options include 0-10 V or 4-20 mA for sensors and external release. The integrated PID controller, power limiter, and motor current limitation features enhance its operational flexibility and safety. The fan also includes a soft start function and thermal overload protection for both electronics and the motor, along with line undervoltage and phase failure detection.

Improper use, such as operating the device in an unbalanced state due to dirt or ice, with severe vibration, in medical equipment with life-sustaining functions, or conveying solids or abrasive particles, is strictly prohibited. Painting the device, allowing connections to come loose, or opening the terminal box during operation are also forbidden. The device should not be used in explosive atmospheres or as a safety component for safety-related functions. Any modifications or conversions without ebm-papst's approval are not permitted.

Regular maintenance is essential for ensuring the long service life and proper operation of the K3G560-PC04-01. This includes checking the fans regularly for proper operation and soiling, with the frequency adjusted based on the degree of soiling. Cleaning should only be performed when the fan is not in motion, and the power supply should be switched off via the control input to prevent accidental start-up. Dry cleaning, such as using compressed air, is the preferred method. Aggressive cleaning agents, acids, alkalis, solvents, or pointed/sharp-edged objects should not be used. All cleaning agents must be completely removed.

A safety inspection should be performed at least every 6 months, including visual inspection of the contact protection cover, blades, housing, and cables for damage. The fastening of cables should be checked and tightened if necessary. The insulation of cables should be inspected for damage, and the impeller should be checked for wear, deposits, corrosion, and damage. The tightness of the cable gland should be verified, and condensation drainage holes should be checked for clogging. Abnormal bearing noise should be investigated, and a vibration test should be performed.

The fan is equipped with maintenance-free ball bearings designed for a service life of 40,000 hours. If bearing replacement becomes necessary after this period, ebm-papst should be contacted. If the device is not operated for a lengthy period, it should be started up and operated at full speed for a specified duration to move the bearings and evaporate any condensate. In cases of severe corrosion on load-bearing or rotating parts, the device should be switched off immediately and replaced, as repairs to these parts are not permitted. If cleaning does not eliminate vibrations, the fan may need rebalancing.

For disposal, the product should be disassembled by qualified personnel into suitable components. Metallic materials like steel, copper, and aluminum are generally recyclable and should be separated. Plastics, insulating materials, cables, wires, and electronic scrap should be disposed of according to proper procedures. Ferrite magnets can be disposed of in the same way as normal iron and steel. Country-specific legal regulations regarding waste disposal must always be observed.

| Manufacturer | ebm-papst |

|---|---|

| Model Number | K3G560-PC04-01 |

| Category | Fan |

| Type | Axial Fan |

| Voltage | 230 V |

| Rated Voltage | 230 V |

| Frequency | 50/60 Hz |

| Impeller Material | Plastic |

| Connector | Terminal box |

| Motor Technology | EC Motor |

Loading...

Loading...