Do you have a question about the ebm-papst K3G355-PJ75-05 and is the answer not in the manual?

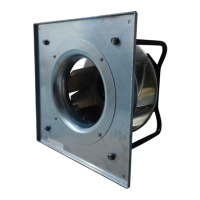

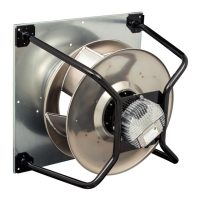

This document provides operating instructions for the K3G355-PJ75-05 device, a built-in fan designed for conveying air.

The K3G355-PJ75-05 is an ebm-papst Mulfingen product, specifically a built-in device for air conveyance. It operates as a 3-phase AC motor (M3G112-EA) with a nominal voltage range of 380-480 VAC and a frequency of 50/60 Hz. The device is designed for stationary systems and is intended for use in power systems with earthed neutral (TN/TT power systems) that meet EN 50160 network quality characteristics. It incorporates an integrated PID controller, soft start, and motor current limit. The fan features integrated protective functions that automatically switch off the motor in case of faults such as rotor position detection error, locked rotor, line under-voltage, or phase failure. It also includes a thermal overload protector (TOP) wired internally for motor protection. The device offers various control options, including PWM controlling and analogue input (0-10 VDC).

Motor: M3G112-EA, 3-phase AC Nominal Voltage Range: 380-480 VAC Frequency: 50/60 Hz Speed: 2400 rpm Power Input: 1100 W Current Draw: 1.7 A Mass: 18 kg Size: 355 mm Motor Size: 112 Number of Blades: 5 Direction of Rotation: Clockwise, seen on rotor Type of Protection: IP55 Insulation Class: "F" Humidity (F) / Environmental Protection Class (H): H1 Ambient Temperature Range: -25°C to 60°C (occasional start-up between -40°C and -25°C is permissible) Motor Bearing: Ball bearing (sealed) Technical Features:

The device is designed for conveying air at an ambient air pressure of 800 mbar to 1050 mbar. It must be installed with a fixed protective device and guard grille that can withstand the kinetic energy of a fan blade at maximum speed and prevent finger access. The fan should be connected to circuits that can be switched off with an all-pole separating switch. Proper cable routing, including a U-shaped loop (siphon) where possible, is crucial to prevent moisture penetration into the terminal box. The device should be operated free of vibrations throughout its speed control range, and any resonance frequencies or excessive vibration levels must be identified and remedied. The maximum vibration severity should not exceed 3.5 mm/s and must be checked every 6 months. For parallel connections on the mains side, the arrangement conforms to IEC 61000-3-12 if the short-circuit power Ssc at the connection point is greater than or equal to 250 times the rated output.

Maintenance includes regular checks of the electrical equipment, replacing loose connections and defective cables immediately. The fan should be inspected for visible external damage and proper function of protective features before switching on. Airflow paths must be checked for foreign objects. For long periods of non-operation, especially in damp environments, the device should be started up and operated at full speed for at least two hours once a month to move bearings and evaporate condensate. Cleaning should be done without high-pressure cleaners, acids, alkalis, solvent-based agents, or sharp-edged objects. A high-voltage test with DC voltage is required, corresponding to the peak value of the AC voltage. Regular visual inspections (at least every 6 months) are recommended for mounting lines, wire insulation, impeller wear/deposits/corrosion, cable gland tightness, and condensate discharge holes. An acoustic check for abnormal bearing noise and a vibration test are also recommended every 6 months. In case of malfunctions, the manual provides a troubleshooting guide with possible causes and remedies, such as cleaning the device for imbalance, removing mechanical blockages, restoring power supply, or correcting faulty connections. The product is largely recyclable, with components made of steel, copper, aluminium, and plastic, and should be disassembled by qualified personnel for proper disposal according to country-specific legal regulations.

Loading...

Loading...