Do you have a question about the ebm-papst K3G097-AS81-81 and is the answer not in the manual?

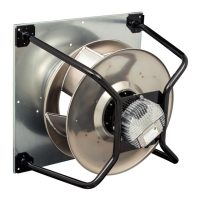

This document outlines the operating instructions for an ebm-papst device, primarily designed as a built-in component for conveying air. It emphasizes safety, proper usage, and maintenance to ensure reliable operation and a long service life.

The device is exclusively designed for air conveyance within DC grids, operating within specified ambient air pressure and temperature ranges. It functions as a built-in component, meaning it is integrated into a larger system or machine. The device is equipped with various technical features to ensure controlled and safe operation. These include a lowering input, an error output (high-side switch), an inverse linear control input (INVLIN), and a power limiter. It also incorporates motor current limitation, a soft start function, and a control input for 0-10 VDC or PWM signals. For protection, it features temperature derating with a fault message via the diagnostic output, overvoltage detection, thermal overload protection for electronics, line undervoltage detection, and reverse polarity protection. The diagnostic output provides information on the fan's status, indicating whether it is operating correctly or if an error has occurred. The device is designed to operate with all protective devices in place and in accordance with the provided operating instructions.

The device is intended for use in systems with Class 1 vehicle electrical system architecture according to EN 50533. It is crucial to use the device only within the permitted ambient temperature range and to ensure that the customer equipment can withstand the mechanical and thermal stresses generated by the product throughout its service life. The device must be operated with all protective devices installed and functioning.

Improper use is strictly prohibited and can be hazardous. This includes operating the device in an unbalanced state due to dirt or ice formation, or in resonant operation with severe vibration. It should not be used in medical equipment with life-sustaining or life-support functions, nor for conveying solids or abrasive particles in the flow medium. Painting the device, operating it with loose connections, or conveying highly corrosive air (unless specifically designed for it) are also forbidden. The device should not be used for conveying air with high dust content, near flammable materials, or in explosive atmospheres. It is not designed to be a safety component or to perform safety-related functions. Operation with completely or partially disassembled or manipulated protective devices is also prohibited. Any applications not explicitly listed as intended uses are considered improper.

When connecting the device, it is essential to check that the information on the nameplate matches the connection data and that the power supply matches the device voltage. Only cables designed for the current level indicated on the nameplate should be used, with a minimum cross-section of AWG 26 / 0.13 mm² and a recommended temperature rating of 105 °C. The device must be operated with a safely isolated power supply. The external leads should be connected according to the application and the provided connection diagram. It is important to ensure that the end of the cable is connected in a dry environment to prevent water ingress, which could damage the device.

Before switching on, the device must be properly installed with all safety mechanisms and professional electrical hookup in place. This includes checking for visible external damage and ensuring that protective devices are functional. Any foreign matter in the fan's airflow paths must be removed. The nominal supply voltage should be applied, and the device started by changing the input signal.

Regular maintenance is crucial for ensuring a long service life and proper operation. This includes checking the device's electrical equipment at regular intervals and immediately replacing any loose connections or defective cables. The fan must be adequately safeguarded with a fixed protective device and guard grill, and operation should cease immediately if a protective device is missing or ineffective.

The device should be stored in a dry, weather-protected, and vibration-free environment, preferably in its original packaging. It should be protected from environmental effects and dirt until final installation. Storage for no longer than one year is recommended to guarantee trouble-free operation and the longest possible service life. Even devices intended for outdoor use should be stored as described prior to commissioning, maintaining the specified storage temperature.

For cleaning, regular checks for proper operation and soiling are necessary, with the frequency adjusted based on the degree of soiling. Dirt deposits on the motor housing can cause overheating, and soiling of the impeller can lead to vibration, shortening the fan's service life and potentially destroying it. In such cases, the fan must be switched off and cleaned immediately. Dry cleaning, such as using compressed air, is the preferred method. Aggressive cleaning agents should not be used, and any cleaning agents used must be completely removed. If severe corrosion is visible on load-bearing or rotating parts, the device must be switched off and replaced, as repair of these parts is not permitted. After cleaning, the fan should be operated at maximum speed for two hours to evaporate any ingressed water. If vibrations persist after cleaning, the fan may need rebalancing. The fan is equipped with maintenance-free ball bearings with a lifetime lubrication designed for 40,000 hours; if bearing replacement is needed after this period, ebm-papst should be contacted. Maintenance intervals should be adapted to the actual level of dust exposure.

Safety inspections include visual checks of the contact protection cover, device blades, housing, cable fastening, and cable insulation for damage at least every six months. The impeller should be visually inspected for wear, deposits, and corrosion, and abnormal bearing noise should be checked acoustically at least every six months. If an imbalance in rotating parts is detected, the device should be cleaned or replaced. If mechanical blockage occurs, the device should be switched off, isolated from the supply, and the blockage removed. In case of line voltage faults, the voltage should be checked, power supply restored, and control signal applied. For faulty connections, the connection should be isolated from the supply and corrected according to the connection diagram. If the motor or electronics are overtemperature, cooling should be improved, and the device allowed to cool down. To reset an error message, the line voltage must be switched off for at least 25 seconds and then switched on again.

If the device is not operated for a lengthy period in a dry installed condition, it should be started up and operated at full speed for one hour at least every four months. If in a damp environment, it should be operated at full speed for at least two hours once a month to move the bearings and allow any condensate to evaporate.

Disassembly for disposal must be performed or supervised by qualified personnel. The product should be disassembled into suitable components for disposal using standard procedures for motors. Heavy parts must be secured before unfastening to prevent them from falling. Components like steel, copper, aluminum, and plastic should be separated for recycling. Ferrite magnets can be disposed of with normal iron and steel. Electronic components and insulating materials should be disposed of according to proper procedures for electronic scrap.

| Manufacturer | ebm-papst |

|---|---|

| Model Number | K3G097-AS81-81 |

| Voltage | 230 V |

| Airflow | 340 m³/h |

| Speed | 3700 rpm |

| Noise Level | 59 dB(A) |

| Impeller diameter | 97 mm |

| Housing material | Plastic |

| Bearing type | Ball bearing |

| Protection class | IP44 |

Loading...

Loading...