Do you have a question about the ebm-papst K3G500-PB24-03 and is the answer not in the manual?

Explains hazard symbols (Danger, Warning, Caution, Note) and their meanings.

Specifies that only qualified personnel can operate the device.

Outlines general safety precautions and workplace cleanliness.

Mentions electrical danger from live terminals and the need for waiting after power disconnection.

Discusses guards and protective devices, and stopping the device if they are missing or ineffective.

Addresses potential interference from electromagnetic radiation and shielding measures.

Warns about hazards from rotating parts and the need for securing the device.

Discusses noise emissions and the need for hearing protection.

Warns about high temperatures on the electronics housing and risk of burns.

Provides instructions for safe transport and handling to prevent damage.

Gives guidelines for storing the device to maintain its condition.

Lists specific conditions and parameters for intended use.

Lists prohibited actions and hazardous operating conditions.

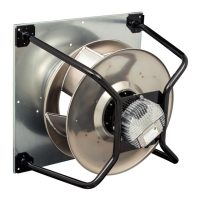

Provides a visual representation of the device with dimensions and labeled parts.

Lists key specifications and performance data of the motor.

Presents energy efficiency data as per EU regulation.

Details device features, materials, and technical specifications.

Specifies requirements for mounting, including screw strength.

Details temperature limits for transport and storage.

Outlines EMC immunity and emission standards compliance.

Instructions and warnings for physically connecting the device.

Safety precautions and requirements for electrical hookup, including fuse assignment.

Guidance on preparing cables and connecting them within the terminal box.

Lists default configuration settings for the device.

Illustrates the wiring diagram for power supply and control connections.

Details various configuration options for inputs, outputs, and functions.

Shows circuit diagrams for hardware inputs, outputs, and communication interfaces.

Outlines steps for verifying connections before operation.

Provides instructions and warnings for starting up the device.

Explains how integrated protective functions react to faults like blocked rotor or phase failure.

Covers causes and remedies for impeller issues like imbalance.

Addresses causes and remedies for the motor failing to turn.

Details issues related to faulty connections and their resolution.

Discusses motor winding faults and replacement remedies.

Covers causes and remedies for inadequate cooling.

Provides a remedy for high ambient temperatures affecting the device.

Advises on correcting operating points causing issues.

Explains LED indicators, warning codes, and status codes for diagnostics.

Details status codes indicated by the LED, their causes, and remedies.

Outlines the procedure and frequency for testing mechanical vibration.

Provides instructions and warnings for cleaning the device safely.

Lists checks and intervals for safety inspections of various components.

Gives recommendations for environmentally friendly disposal of the product.

This document describes the K3G500-PB24-03, a RadiPac fan designed as a built-in device for conveying air according to its technical data. It is intended for use in stationary systems within specific power systems (TN/TT, phase conductor grounding, or IT power systems) and networks with EN 50160 quality characteristics. The device is suitable for conveying air at ambient pressures between 800 mbar and 1050 mbar, within a permitted ambient temperature range of -40 °C to 45 °C. Occasional start-up at temperatures between -40 °C and -25 °C is permitted, but continuous operation below -25 °C requires a fan design with special low-temperature bearings. All maintenance work must be performed according to the instructions.

The device is a built-in component and must be adequately safeguarded by the owner with a fixed protective device and guard grill. It features operation and alarm display with an LED, external 15-50 VDC input for parameterization, an alarm relay, integrated PI controller, configurable inputs/outputs (I/O), MODBUS V6.3, motor current limitation, RS-485 MODBUS-RTU, and soft start. A voltage output of 3.3-24 VDC (Pmax = 800 mW) is provided, along with a control interface with SELV potential safely disconnected from the mains. Thermal overload protection for electronics/motor and line undervoltage/phase failure detection are integrated.

The device's control lines should be routed separately from the supply line, maintaining a clearance of > 10 cm. Water ingress into wires or cables must be prevented by ensuring the cable end is connected in a dry environment. Only AC/DC-sensitive residual current devices (type B or B+) are permissible if an RCD is required. The starting current (LRA) is equal to or less than the nominal current (FLA) due to locked-rotor protection.

Mechanical connection requires careful handling due to the device's weight (>25 kg), necessitating suitable hoisting equipment and safety shoes/cut-resistant gloves. The fan must not be subjected to force or excessive vibration from the installation. If connected to air ducts, the connection should be vibration-isolated. Screws must be secured against unintentional loosening (e.g., with self-locking screws).

Electrical connection requires checking that nameplate data matches connection data and that the power supply matches the device voltage. Only cables designed for the indicated current level and 105 °C cables are recommended. The protective earth must have a cross-section equal to or greater than the phase conductor. The minimum cable cross-section is AWG 26 / 0.13 mm². The protective earth contact resistance must comply with EN 61800-5-1. An additional protective earth conductor may be necessary.

The terminal box provides connections for the supply line and control/relay lines. Recommended stripped lengths are provided. The cable glands must be sealed and provide strain relief. Cables should be routed in a U-shaped loop to prevent moisture ingress. Factory settings include PWM control, fan/device address 01, max. PWM 100%, min. PWM 5%, and saving set values to EEPROM. Set value requirement is analog (linear), and the direction of action for parameter sets 1 and 2 is positive (heating).

The device automatically switches off in case of:

The device should not be repaired by the user; it must be sent to ebm-papst for repair or replacement. Before any work, the device must be switched off, and a five-minute waiting period observed to allow terminals to discharge. If control voltage or a stored speed set value is applied, the motor may restart automatically after a power failure, posing an injury risk.

If the device is not operated for a lengthy period (installed in a dry environment), it should be started and operated at full speed for one hour every four months. In a damp environment (e.g., outdoors), this should be done for at least three hours once a month to move bearings and evaporate condensate.

An LED on the electronics housing indicates motor status with various colors and flash codes (2 Hz frequency, 3-second pause). Green indicates no warning/fault, orange indicates a warning (no user intervention required), and red indicates an error. Multiple simultaneous errors display their flash codes in succession, with errors prioritized over warnings.

Orange LED (Warning):

Red LED (Error - Manual Reset Required):

Fans should be checked regularly for proper operation and soiling. Cleaning frequency depends on the degree of soiling. Only clean when not in motion, and do not disconnect the fan from the power supply; just switch it off via the control input to prevent start-up. Dirt deposits can cause motor overheating or impeller vibration, shortening service life. Severe vibration can destroy the fan, requiring immediate shutdown and cleaning. The preferred method is dry cleaning (e.g., compressed air). Aggressive cleaning agents, high-pressure cleaners, acids, alkalis, solvents, or sharp objects must not be used. All cleaning agents must be completely removed. If severe corrosion is visible, replace the device; repair of load-bearing or rotating parts is not permitted. After cleaning, operate the fan for 2 hours at maximum speed to evaporate any water. If vibrations persist, the fan may need rebalancing. The maintenance-free ball bearings have a lifetime lubrication designed for 40,000 hours.

A high-voltage test should be performed with DC voltage due to the integrated EMC filter's Y capacitors.

Disassembly must be performed or supervised by qualified personnel. The product is mostly made of steel, copper, aluminum, and plastic. Components should be separated for recycling into categories: steel and iron, aluminum, non-ferrous metal (motor windings), plastics (with brominated flame retardants), insulating materials, cables and wires, and electronic scrap (circuit boards). Ferrite magnets can be disposed of like normal iron and steel. Electrical insulating materials in the product, cables, and wires are similar and treated the same. Electrolytic capacitors are also considered. Contact ebm-papst for any other disposal questions.

Loading...

Loading...