Do you have a question about the ebm-papst K3G560-HE07-01 and is the answer not in the manual?

This document outlines the operating instructions for a built-in device designed for conveying air. It covers essential safety regulations, technical data, connection procedures, startup, integrated protective features, and maintenance guidelines.

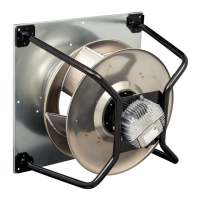

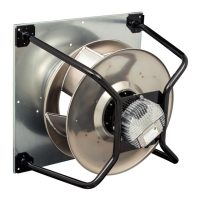

The device is primarily an air-conveying unit, specifically a RadiPac fan, designed to be integrated into larger systems. Its core function is to move air according to its technical specifications. The fan operates with a three-phase motor and includes an integrated EMC filter for compliance with electromagnetic compatibility limits. It features a robust design with components made from sheet steel, galvanized sheet steel, and die-cast aluminum, ensuring durability and performance in industrial environments. The motor is equipped with ball bearings designed for a long service life.

The device incorporates an integrated PID controller, a power limiter, and motor current limitation for optimized operation. It supports various control inputs, including 0-10 VDC and PWM, and offers outputs for slave control and motor modulation level. Communication is facilitated via an RS-485 MODBUS-RTU interface. Safety features include thermal overload protection for both electronics and the motor, as well as line undervoltage and phase failure detection. The device is designed for stationary systems and is suitable for continuous operation within specified ambient temperature ranges, with occasional start-up permitted at lower temperatures.

The device is intended for use in power systems with grounded neutral (TN/TT), phase conductor grounding, or IT power systems, and must operate within network quality characteristics as per EN 50160. It is designed for conveying air at ambient air pressures between 800 mbar and 1050 mbar. The device should always be operated with all protective devices in place.

The fan offers flexible installation positions, with the shaft typically horizontal or the rotor on the bottom, though a rotor-on-top configuration can be requested. It includes an inlet ring with a pressure tap for measurement purposes. The device's control system allows for parameter adjustments, including mode settings (e.g., PWM control), fan/device address, and maximum/minimum PWM percentages. It can save set values to EEPROM, ensuring consistent operation. The direction of action for control parameters can be set to positive (heating).

For electrical connection, the device requires a three-phase supply and includes terminals for line connections (L1, L2, L3) and a protective earth (PE) connection. It also provides status relay contacts (NO, COM, NC) for failure indication. Control inputs include analog inputs (0-10 V, 4-20 mA) and digital inputs for enabling electronics, switching parameter sets, and selecting the controller's direction of action. Fixed voltage outputs (10 VDC, 20 VDC) are available for powering external devices or sensors.

The device is equipped with locked-rotor protection, ensuring that the starting current (LRA) is less than or equal to the nominal current (FLA). It also has integrated protective functions that automatically switch off the motor in case of rotor position detection errors, blocked rotor, line undervoltage, or phase failure, with automatic restart capabilities once the fault is cleared.

Regular maintenance is crucial for ensuring a long service life and proper operation. The device should be checked periodically for proper functioning and soiling, with the frequency adjusted based on the degree of soiling. Cleaning should only be performed when the device is not in motion and disconnected from the power supply to prevent accidental start-up. Dry cleaning, preferably using compressed air, is the recommended method. Aggressive cleaning agents, water jets, high-pressure cleaners, acids, alkalis, solvents, or sharp objects should not be used. All cleaning agents must be completely removed after cleaning.

The fan is equipped with maintenance-free ball bearings with a designed service life of 40,000 hours. If bearing replacement becomes necessary after this period, ebm-papst should be contacted. Maintenance intervals should be adapted to the actual level of dust exposure.

A safety inspection should be conducted at least every six months. This includes visually inspecting the contact protection cover for intactness or damage, checking the device for damage to blades and housing, and verifying the fastening of cables. The insulation of cables should be checked for damage, and the impeller inspected for wear, deposits, corrosion, and damage. The tightness of cable glands should be re-tightened or replaced if damaged, and condensation drainage holes checked for clogging. Abnormal bearing noise should be investigated, and the device replaced if necessary.

Vibration testing is recommended every six months to check for mechanical vibration based on ISO 14694. The maximum permissible vibration severity should not exceed 3.5 mm/s, measured at the motor fastening diameter on the motor support plate in both axial and perpendicular directions. If cleaning does not eliminate vibrations, the fan may need to be rebalanced by ebm-papst.

For devices not operated for lengthy periods, especially in damp environments, it is recommended to start and operate the fan at full speed for at least four hours once a month to move the bearings and evaporate any condensate. In dry environments, this should be done for one hour every four months.

In the event of malfunctions such as the impeller not running smoothly, the motor not turning, deficient cooling, ambient temperature too high, or impermissible point of operation, troubleshooting steps are provided. These include cleaning the device, checking for mechanical blockages, verifying line voltage, correcting faulty connections, improving cooling, reducing ambient temperature, or adjusting the operating point. If these remedies do not resolve the issue, ebm-papst should be contacted for further assistance.

Disassembly of the product for disposal should be performed by qualified personnel, separating components into categories such as steel, iron, aluminum, non-ferrous metals, plastics, insulating materials, cables, wires, and electronic scrap. Ferrite magnets can be disposed of with normal iron and steel. Country-specific legal regulations for disposal must always be observed.

| Manufacturer | ebm-papst |

|---|---|

| Model | K3G560-HE07-01 |

| Category | Fan |

| Voltage | 230 V |

| Frequency | 50/60 Hz |

| Impeller Material | Plastic |

| Protection Class | IP54 |

| Insulation Class | F |

| Connection | Terminal box |

Loading...

Loading...