7

STARTER SYSTEM

CS-370ES

CS-420ES

Working principle

1. When starter grip is pulled, rope reel (D) rotates.

2. The rotation force of rope reel (D) is transmitted

to pawl catcher (F) by power spring (E) that is

connected with rope reel (D) and pawl catcher (F).

3. Pawl catcher (F) engages with starter pawls on

flywheel to turn crankshaft.

4. The load from compression pressure in cylinder

will keep crankshaft from rotating as power spring

(E) is twisted and accumulates energy.

5. Starter grip is pulled further; more energy is

stored in power spring (E) until the accumulated

energy is enough to overcome the compression

pressure in cylinder.

6. When accumulated energy in power spring (E)

overcomes the load from compression pressure in

cylinder, crankshaft will be rotated.

7. Power spring absorbs compression resistance of

cylinder and snatch back of engine during starting

action.

8. When starter rope is released, rope reel (D) is

returned together with power spring (E) and pawl

catcher (F) by rewind spring tension.

9. After engine starts, starter pawls pivot outward by

centrifugal force and disengage from pawl catcher

(F).

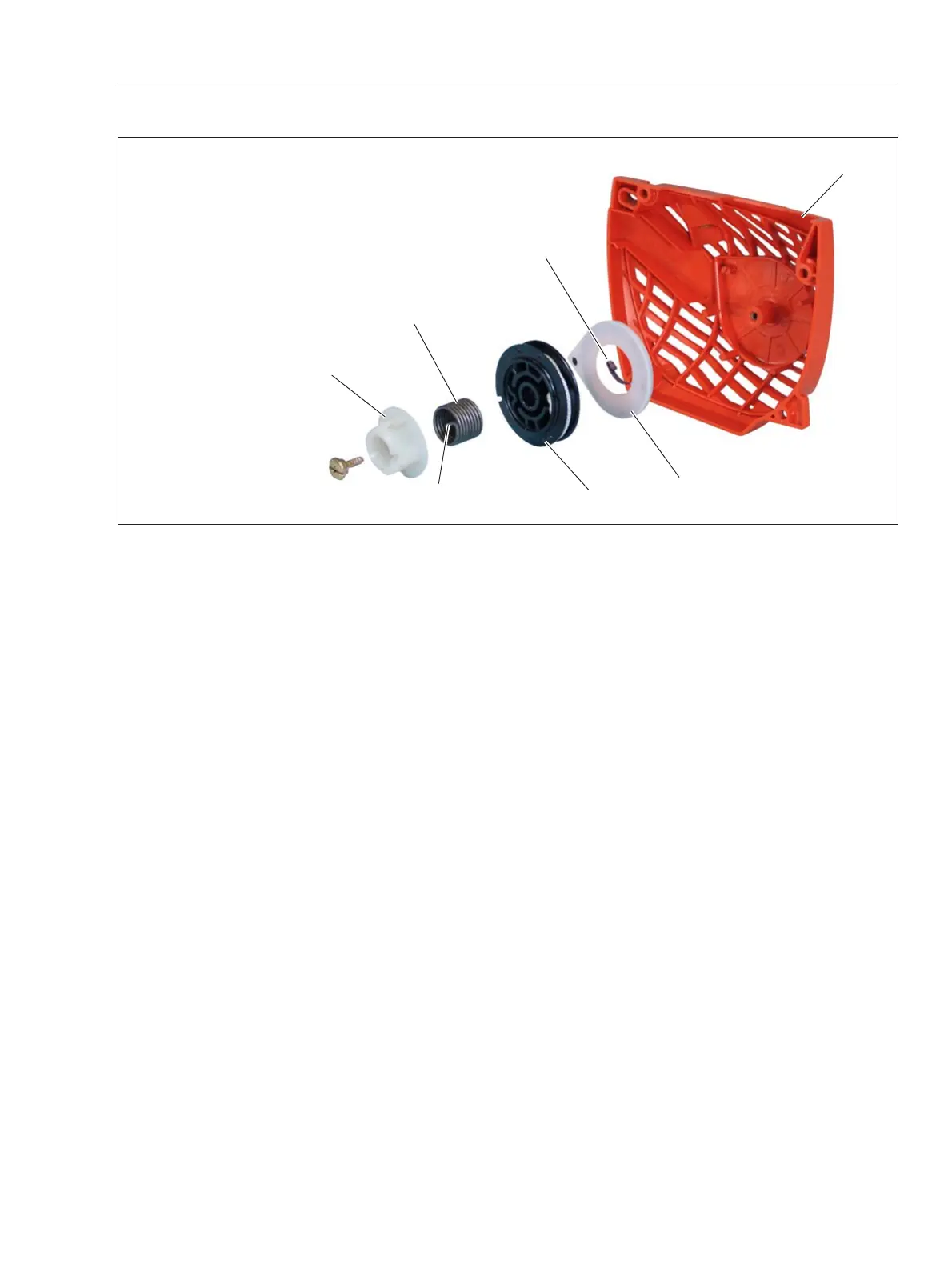

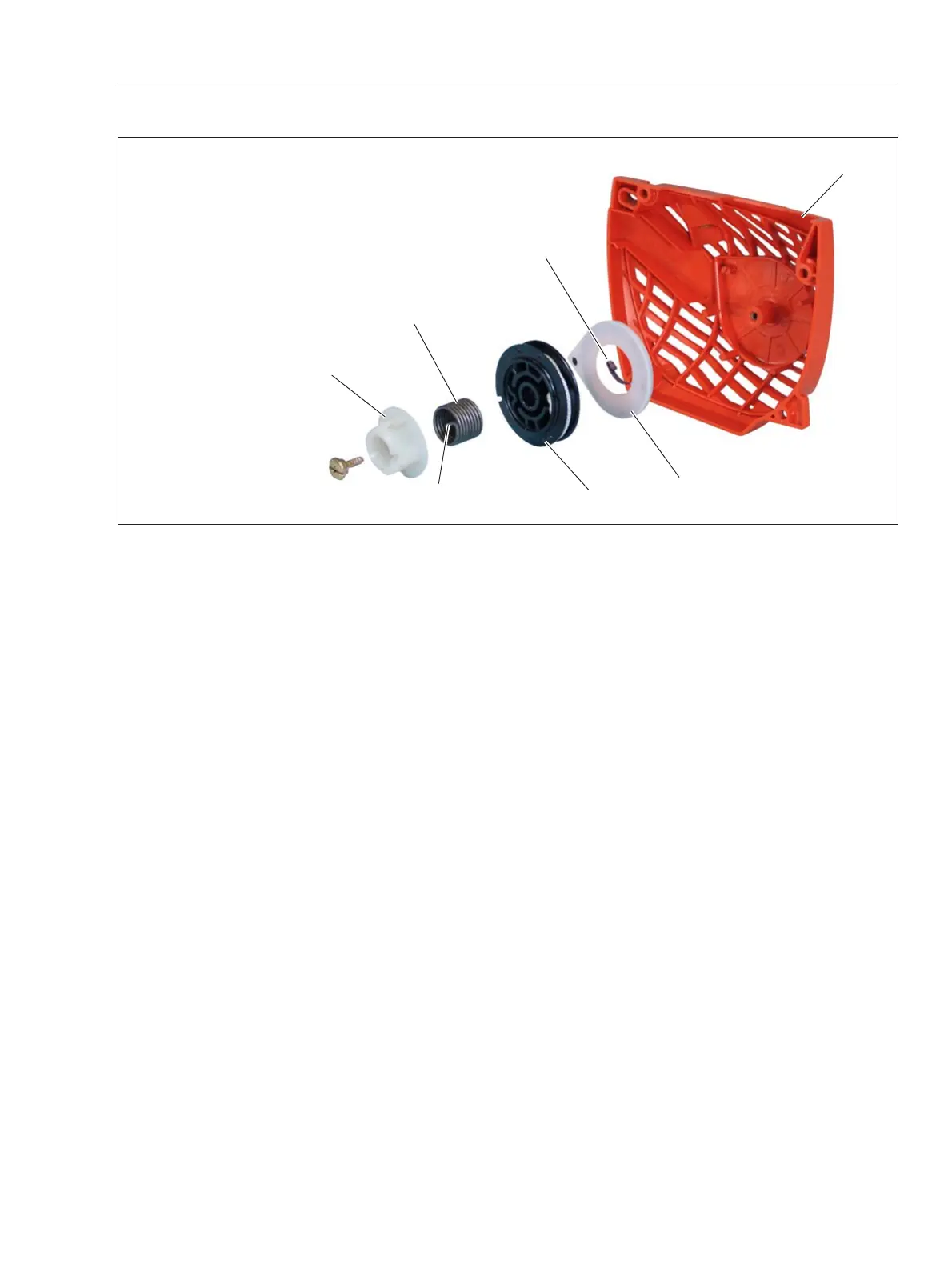

2 STARTER SYSTEM (ES starter)

(A) Starter case

(B) Rewind spring

(C) Rewind spring case assembly

(D) Rope reel

(E) Power Spring

(e) Hook end of power spring

(F) Pawl catcher

F

E

A

D

C

B

e

Construction

1. Rewind spring case assembly (C) is installed

inside starter case (A).

2. Rope reel (D) with starter rope is installed on

rewind spring case assembly.

3. Hook located on the backside of rope reel

engages with end of rewind spring (B).

4. Power spring (E) is installed on rope reel.

5. Hook of power spring engages with rope reel and

top end hook (e) of power spring engages with pawl

catcher (F).

Loading...

Loading...