|5

Utility grid recovers:

The backup operation is disabled automatically and the loads are supplied

with energy from the power grid and PV system.

Backup switching time

:

Under normal circumstances, the back up switching time during grid outage

is less than 20 ms, which will be more than 20ms when low-voltage ride-

through function is enabled by default based on local electrical code.

You can set charging and discharging limit in the EcoFlow app

.

BACK-UP OVERLOAD PROTECTION

When single overload protection occurs, the inverter can restart

automatically. However, the restarting time will be extended (5 min at

most) if it repeats. For a faster restarting, try it via app. Try removing the

loads which may cause very high start-up current surges.

OPTIMIZE SOLAR AGAINST SHADE

The system will optimize solar generation in shaded conditions at your

setup intervals to track the maximum power point. Solar generation may

fluctuate under this condition.

This Function is disabled by default.

To enable it, switch on Commissioning > Optional setup > Optimize solar

generation in the EcoFlow Pro app when the installer performs system

commissioning.

RCR OR DRM DETECTION

Ripple control receiver (RCR) is an interface between a PV system and

power grid company that enables the grid operator to reduce the feed-

in power, required in Germany and some European regions for more than

25kW inverters.

Demand Response Mode (DRM) which enables the inverter to respond to

signals sent to it remotely, is required in Australia.

Generally, if the grid is overloaded, the utility company will specify whether

the PV system should reduce the feed-in power to 0%, 30%, 60% of the

rated power.

This Function is enabled by default.

To disable it, switch on Commissioning > Testing > DI active scheduling in

the EcoFlow Pro app when the installer performs system commissioning.

Or custom the DI values.

CUSTOM PARAMETER

You can custom the following parameters in Commissioning > Device

settings > Customize settings in the EcoFlow Pro app when the installer

performs system commissioning.

• Connection parameters

• Voltage Protection parameters

• Frequency Protection parameters

• Reactive Power parameters

• Other parameters

System Maintenance &

Replacement

WARNING

• Turn off the AC and DC switches of the inverter and the battery junction

box when maintaining the electric equipment or power distribution

equipment connected the equipment.

• Wear proper PPE before any operations.

• Place temporary warning signs or erect fences to prevent unauthorized

access to the maintenance site.

ROUTINE MAINTENANCE

Recommended maintenance interval for the following item is once every 6

months. Troubleshoot if there is any abnormality.

Check

Item

Check Method

System

cleanliness

Check periodically that the heat sinks are free from obstacles

and dust.

If there is any stain or dirt on the surface, use a dry, soft cloth

to wipe it off and prohibit the use of stain removing powder,

any liquid, coarse brush, abrasives or hard objects to clean

the equipment.

Ensure equipment ventilation and heat dissipation.

If you need to remove the air inlet baffle for cleaning, contact

the installer.

System

running

status

Check that the equipment is not damaged or deformed.

Check that the equipment operates with no abnormal sound.

Check that all equipment parameters are correctly set during

operation.

Electrical

connection

Check that cables are secured.

Check that cables are intact.

Grounding

reliability

Check that ground cables are securely connected.

Seal ability

Check that unused terminals, ports, waterproof covers are

locked as delivered.

Fan

Check whether the fan generates abnormal noise during

operation, whether the fan is covered by some objects

nearby.

If any, remove foreign objects from or beside the fan.

If the abnormal noise persists, replace the fan. For details,

see Replacing the Inverter Fan.

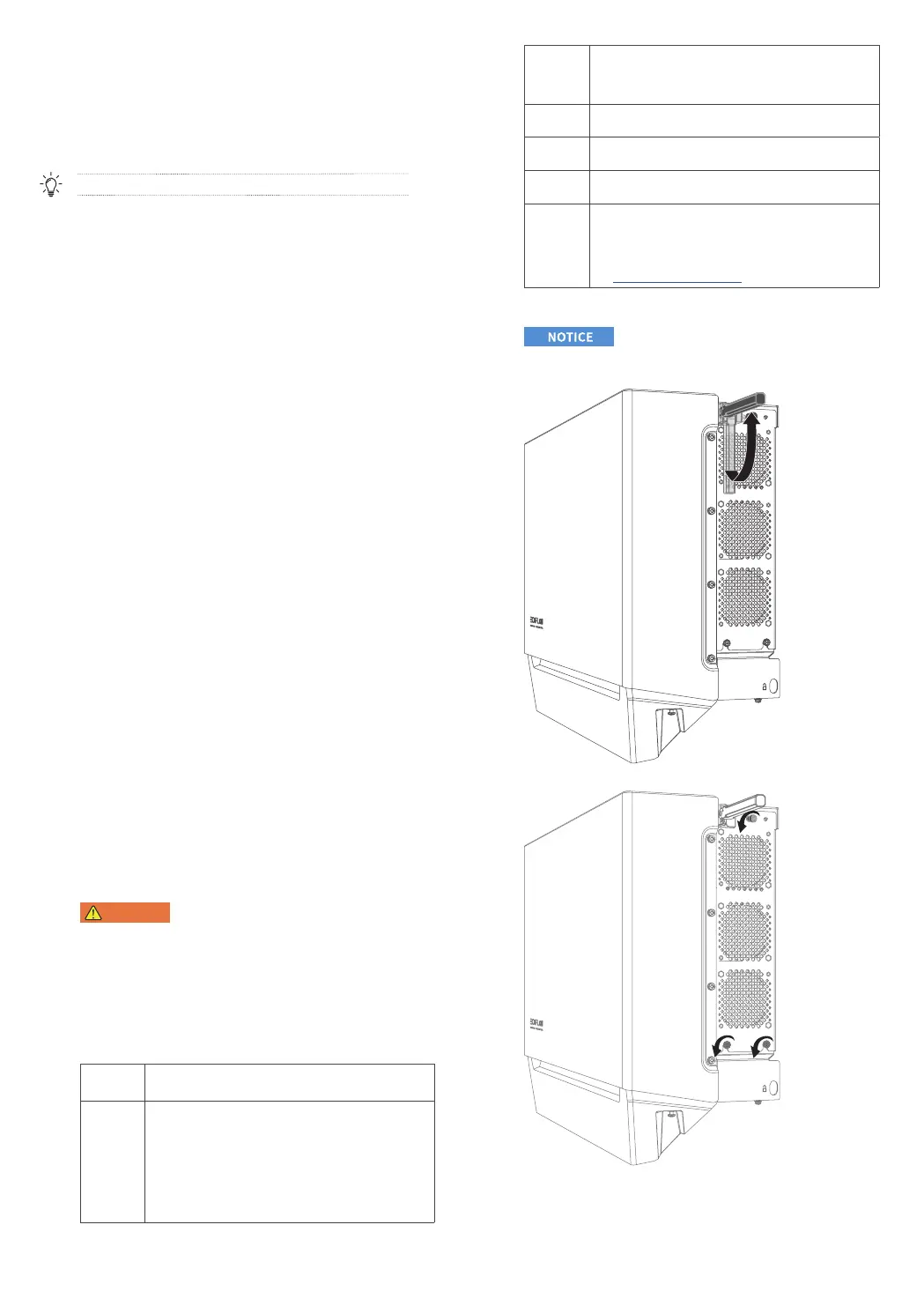

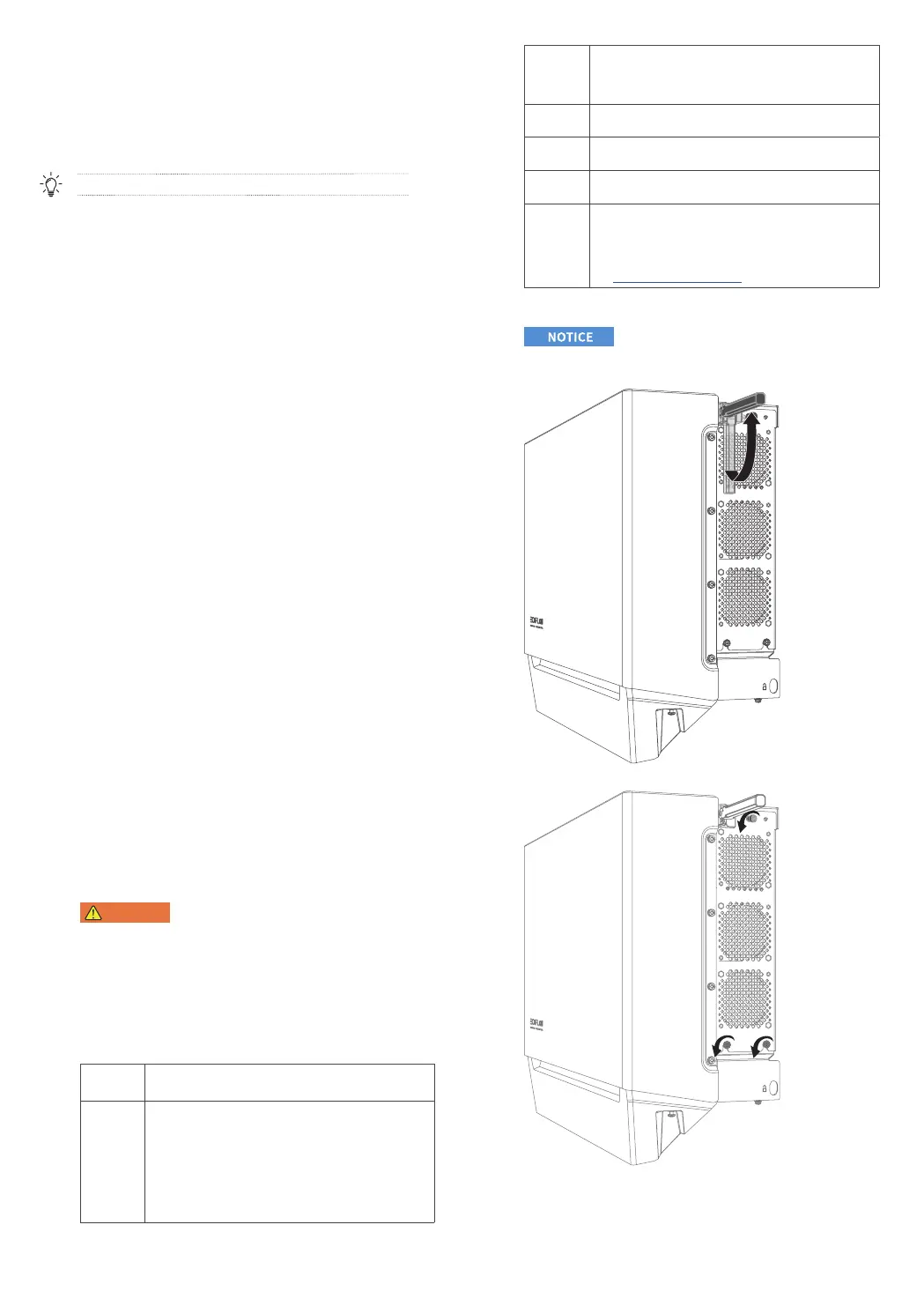

REPLACING THE INVERTER FAN

• You can only replace the whole fan module instead of the individual fan.

To remove the inverter fan:

1. Lift up the handle.

2. Loosen the bottom screws, and then the top screw, using a Phillips

screwdriver.

Loading...

Loading...