6

5.0 TROUBLESHOOTING

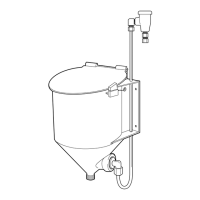

The following Troubleshooting procedures are specific to the VANGUARD Wash Max Reservoir System. These

procedures assume that the VANGUARD EcoCenter, Control Max or VANGUARD 2026 are fully operational - if necessary

to troubleshoot these components, refer to the VANGUARD EcoCenter, Control Max or VANGUARD 2026 I/O Manuals.

Symptom Action

5.1 Inadequate Water To/From Reservoir Into

Dishmachine

Observe whether or not effluent is flowing from the RESER-

VOIR into the dishmachine while controller is in “feed”

condition. Water volume should be a minimum of 1 GPM.

1. If there is no (or very little) effluent flow:

a. Check and insure RESERVOIR cover is completely

closed (safety switch closes when cover is at cor-

rect angle).

b. Check to insure all shut-off valves (and needle

valve) at the water source are fully open.

c. Check for 24 volts at the solenoid valve coil. If no 24

volts, refer to Step C - NO POWER TO SOLENOID.

If 24 volts, check to make sure the valve is opening.

If it is not opening, it is defective and must be

replaced.

d. Check for clogging in the water line, the solenoid

valve/line strainer, and the vacuum breaker (i.e.,

loosen compression fittings to check for water).

e. Check for broken or plugged spray nozzle. Check

for blocked or crimped product outlet (Mayon) tub-

ing.

2. If there is effluent flow but less than 1 gpm, check for 12

psi (.844 kgm/ cm2) minimum water pressure at outlet

side of vacuum breaker: use the Guardian Pressure

Tester (fitting with pressure gauge P/N 9270-1O77). If

pressure is less than 12 psi (.844 kgm/cm2):

a. Check to insure no kinks in water feed tube, mini-

mum bends and length of feed tube, and for pos-

sible clogging of shut-off/needle valve, solenoid

valve, etc. as described above. Check pressure

reducing valve if present.

b. If low water pressure persists, convert the 1/4" (6.3

mm) water feed tube to 3/8" (9.5mm) tubing (Guard-

ian Low Pressure Kit, P/N 9237-6003). This will

correct or help most low water pressure problems.

Loading...

Loading...