7

Symptom Action

5.2 Low Product (effluent) Concentration Causing

False Alarm

If the alarm repeatedly goes off with product still In the

reservoir (presuming delay time is properly adjusted) prod-

uct is not being dissolved. Effluent concentration should be

a minimum of 5O drops (Titrate 5 - Indicator P) for “solid”

Power Activator detergents.

1. If concentration of effluent is low:

a. Check for low water volume and low water pressure

(see 1 and 2 on page 5).

b. Check to insure cap is removed from detergent

“capsule.

c. Check for misaligned, partially plugged or broken

spray nozzle.

d. Check for water temperature being too cold (solubil-

ity is greatly decreased at temperatures below 120°

F (48.9° C).

2. If effluent concentration is still inadequate (after check-

ing 1a-e) install alternate 5.6 nozzle to increase effluent

concentration (Spray Nozzle P/N 8531-2213). If effluent

concentration is checked to be okay and false or prema-

ture empty capsule alarm still occurs:

a. Check to insure delay time is set long enough (do

not exceed cycle time on timed cycle machines,

including D-Energizer controlled machines).

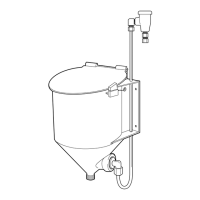

1. Check for water supply to solenoid valve. If no water to

valve, check:

a. Needle valve open and water coming from it.

b. Make sure tubing is not plugged or crimped and that

there is water at the solenoid valve.

2. Check for water from solenoid valve with controller in a

feed condition. If no water check for:

a. Defective valve coil, plunger, spring, or diaphragm.

b. Plugged line strainer in solenoid valve. If there is

water through the solenoid valve, check:

c. Crimped or plugged tubing to reservoir, defective

vacuum breaker or plugged spray nozzle.

If there is excessive overshoot titration in the wash tank,

make necessary adjustments to the overshoot control board

reducing the percentage of "on" time. If adjustments do not

alter the pulsed feed time/rate, replace the Overshoot Con-

trol board. If there is a pulsed feed but overshoot is exces-

sive and cannot be controlled, reduce feed water tempera-

ture.

5.3 Power to Solenoid Valve - No water Feed to

Reservoir

5.4 Excessive Overshoot (POWER ACTIVATOR

only)

Loading...

Loading...