4

Wash Max

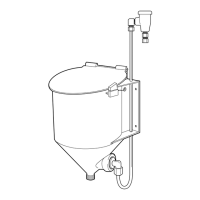

Figure 4-3

4.5 Determining the Reservoir Water Supply

The hot water supply for the VANGUARD Wash Max

Reservoir should fall within the range 120° F (48.9°C) to

150°F (65.5°C.). It must be a minimum of 12 psi (.844 kgm/

cm2) flow pressure with a minimum of 1 gallon per minute

(.063 liter/sec.) water flow.

1. Select the point for connection to the water supply so

that there is a minimum distance between the water

source and the reservoir. If this distance is less than 15'

(4.6 meters) and a minimum of 12 pounds (.844 kgm/

cm2) flow pressure is available, 1/4" O.D. copper tubing

is recommended,

refer to Figure 4-3.

If this distance is greater than 15' (4.6 meters) and/or

less than 12 pounds flow pressure (.844 kgm/cm2),

3/8" copper tubing is recommended for optimum perfor-

mance.

NOTE: DO NOT USE 180°F WATER SOURCE.

4.6 Plumbing into the Water Supply

1. Shut off water supply. Tap into the water source and

install the needle valve supplied with the reservoir,

refer

to Figure 4-3.

The needle valve provides a means to regulate water

flow to the dispenser and it permits servicing the sole-

noid valve without the need to shut off the main water

supply.

2. Install copper tubing between the needle valve and the

solenoid valve at bottom of detergent controller cabinet.

3. Install a length of copper tubing between the solenoid

valve and the vacuum breaker on the VANGUARD

Wash Max Reservoir.

4.7 Start-up Procedures

1. Adjust the VANGUARD EcoCenter, Control Max or

VANGUARD 2026 for proper detergent concentration.

Refer to the respective I/O Manual for instructions.

2. Fill the dishmachine with fresh water and turn on the

dishmachine with no detergent in the reservoir. The

controller will call for feed.

3. Check for water leaks and proper safety switch opera-

tion by lifting cover - the water flow should stop.

NOTE: Refer to Sections 4.8 - 4.11 only if you are using

the Guardian or Power Activator dispensers.

4.8 Guardian

Insure the GUARDIAN nameplate and safety label is neatly

and firmly attached to the front side of the reservoir. The

surface must be clean for permanent attachment. Attach the

GUARDIAN wall chart where it can easily be seen by the

dishmachine operators.

When the reservoir is used with a powdered GUARDIAN

detergent, the large fine mesh GUARDIAN screen must be

DETERGENT

CONTROLLER

SOLENOID VALVE

HOT WATER

SOURCE

NEEDLE

VALVE

TO WASH

TANK

Figure 4-4

inserted into the reservoir (before adding product). The

screen is installed with the small knob at the center top of the

screen facing up. The screen retainer ring is next inserted,

snug against the outer rim of the screen (with the prongs up).

This retainer ring is to hold the screen firmly in place,

refer

to Figure 4-4.

Up to 6 pounds (2.7 kg) of GUARDIAN detergent can now

be added to the GUARDIAN reservoir.

NOTE: Always wet a new screen before adding product

to avoid potential powder sift through.

Adjust the Senso-matic 26 for proper detergent concentra-

tion. Refer to Senso-Matic 26 I/O Manual (#6435) for details.

GUARDIAN

SCREEN

RETAINER

RING

POWER

ACTIVATOR

GRATE

Loading...

Loading...