15

MANUAL FOR ECOSOFT PINK SOFTENERS

This manual is the intellectual property of Ecoso. Copying and reprinng is prohibited. © 2024

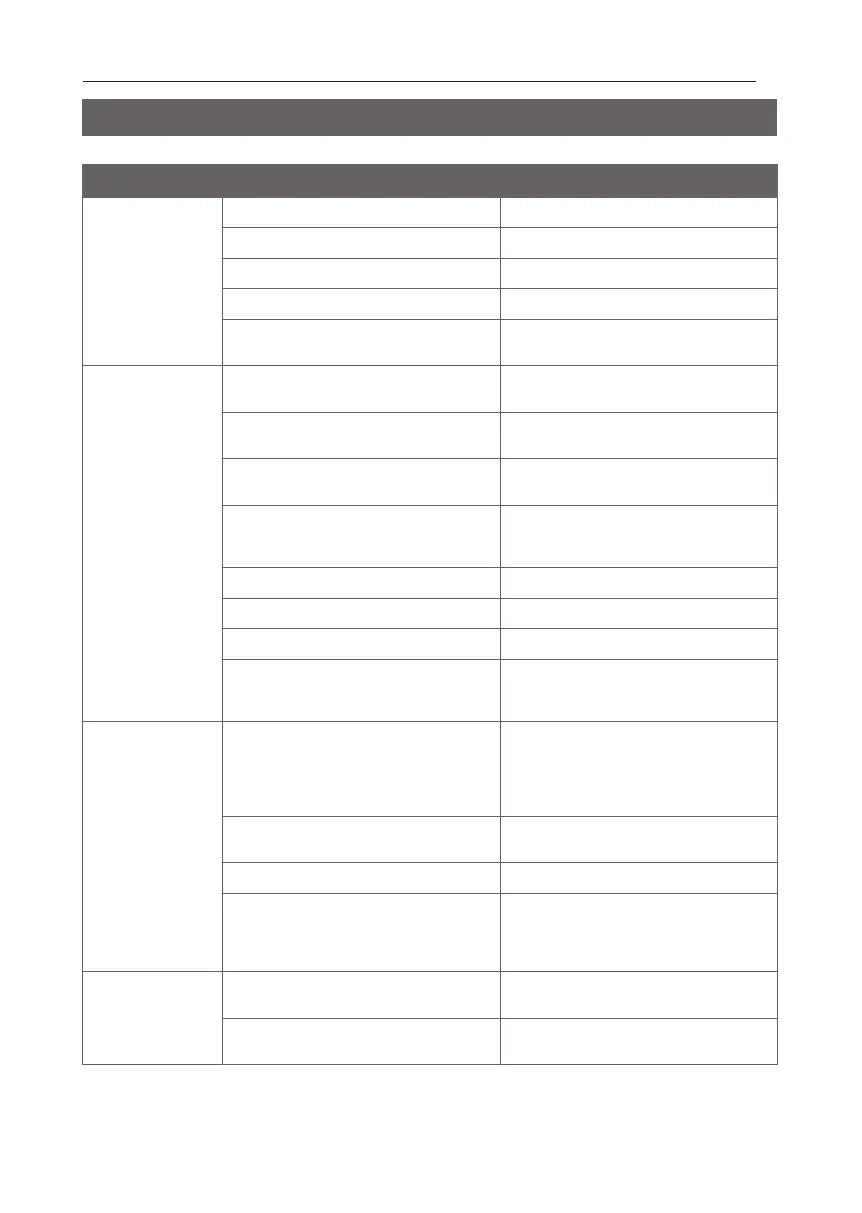

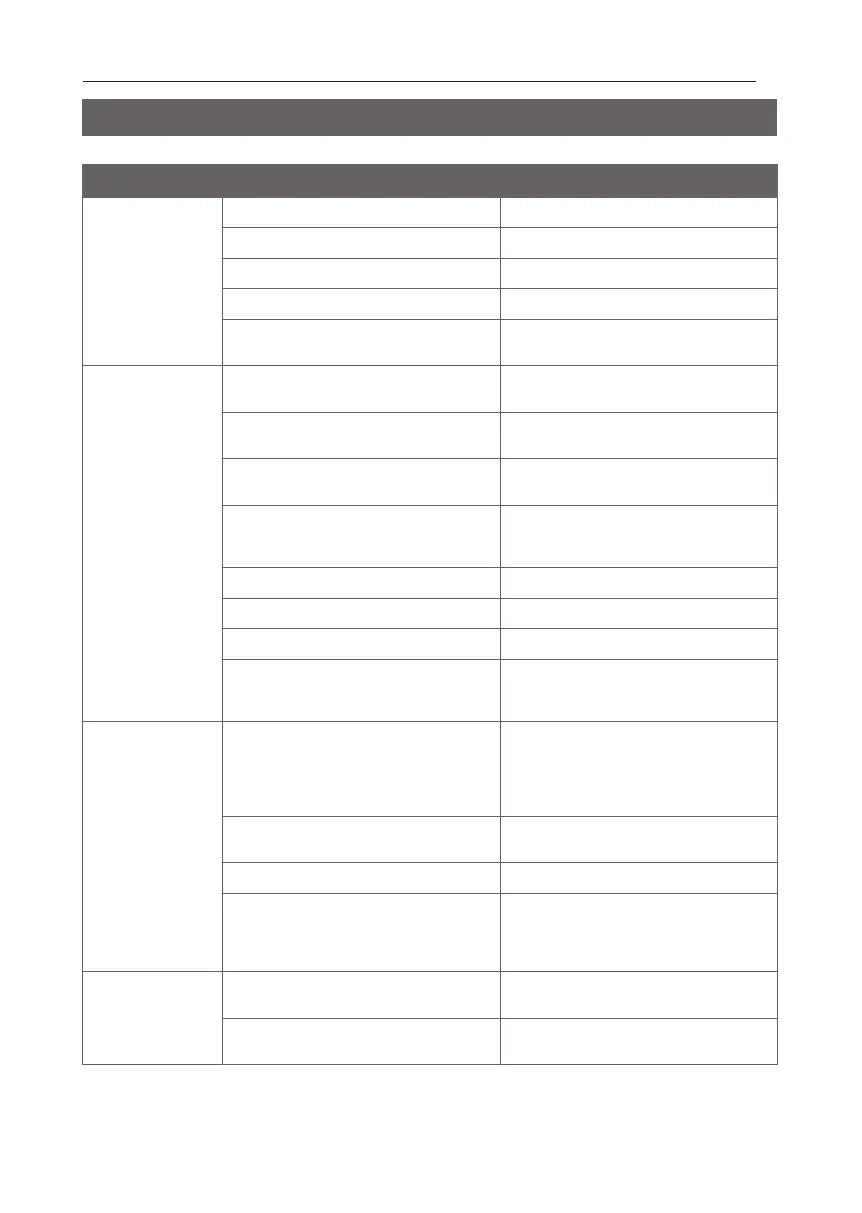

9. TROUBLESHOOTING

Problem Cause Correcon

1. Decreased

service ow

capacity

Decreased supply water pressure Increase supply water pressure

Clogged lter bed See paragraph 3

Obstructed/clogged drain line Clean the drain line

Clogged control valve Inspect and clean the control valve

NHWBP/MAV failure (if used)

Inspect and repair the motorized

valve

2. Decreased

quality of treated

water

Faulty chemical analysis of water

Perform one more test using freshly

prepared reagents

Supply water chemistry has changed

Make new check analysis and if

changed contact your dealer

Bypass valve is set to bypass

Turn bypass valve to operang

posion

Riser pipe or seals are damaged

Take apart the lter, inspect and

replace or lubricate pipe and seals if

necessary

Clogged lter bed See paragraph 3

Filter media loss See paragraph 4

Improper lter regeneraon See paragraph 6

Leakage of raw water inside the

control valve

Take apart the control valve, inspect

and replace or lubricate the seals if

needed

3. Clogged lter

bed

Insucient backwash ow rate

Check backwash ow rate. If supply

pressure is within the limits and the

ow rate is insucient, inspect and

clean the drain line ow control or

replace it if needed

Insucient backwash stage

Increase the duraon of backwash

stage

Clogged top distributor Clean the top distributor

Excessive backwash ow rate

Measure backwash ow rate. If

supply pressure is normal and the

ow rate is exceeding, consider

changing the drain line ow control

4. Filter media

entrainment

Filter media is entrained and

discharged during backwash

Replace the top distributor if needed

Filter media is entrained and

discharged during service

Replace the boom distributor if

needed

Loading...

Loading...