64

CAUTION: CAL Err St may result from a sensor that has not reached thermal equilibrium.

Nitrogen Production Flow Rate Check Procedure

The production rate of the nitrogen generator can be verified using the production flow meter in the

nitrogen generator cabinet (see section 6.j., for the Generator Configuration Diagrams).

1. With the nitrogen generator powered and in the nitrogen production mode:

a. Open the nitrogen production flow meter isolation ball valve to automatically start the

nitrogen generator.

b. Close the regulated and fast fill valves on the air maintenance device (AMD) to the fire

sprinkler system(s).

c. Read and document the nitrogen production flow rate on the nitrogen production flow meter.

i. Flow rate indicated is in standard cubic feet per hour (SCFH).

ii. The production rate is measured using the center of the silver ball in the flow meter.

d. Open the regulated valve on the AMD to the fire sprinkler system(s).

e. Close the flow meter isolation ball valve.

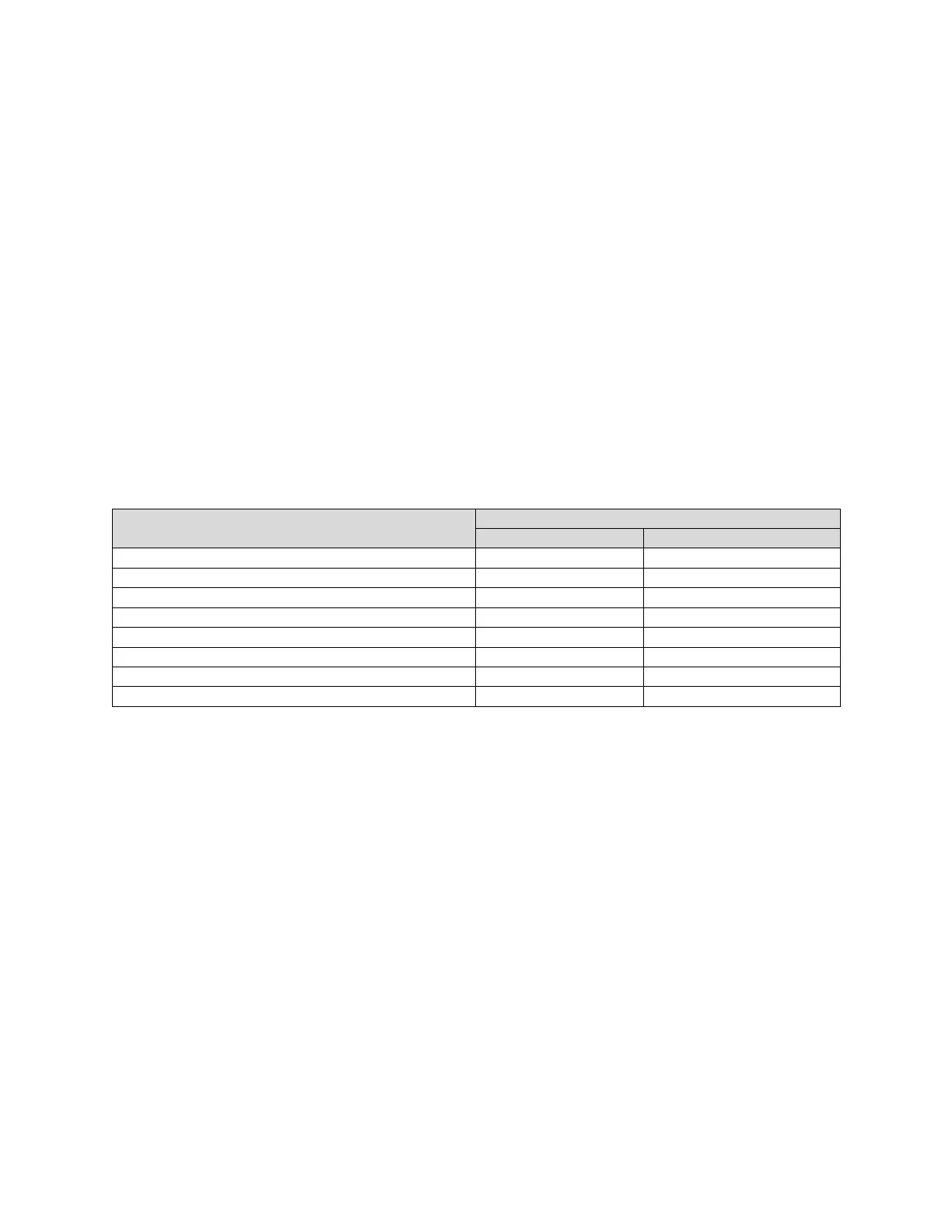

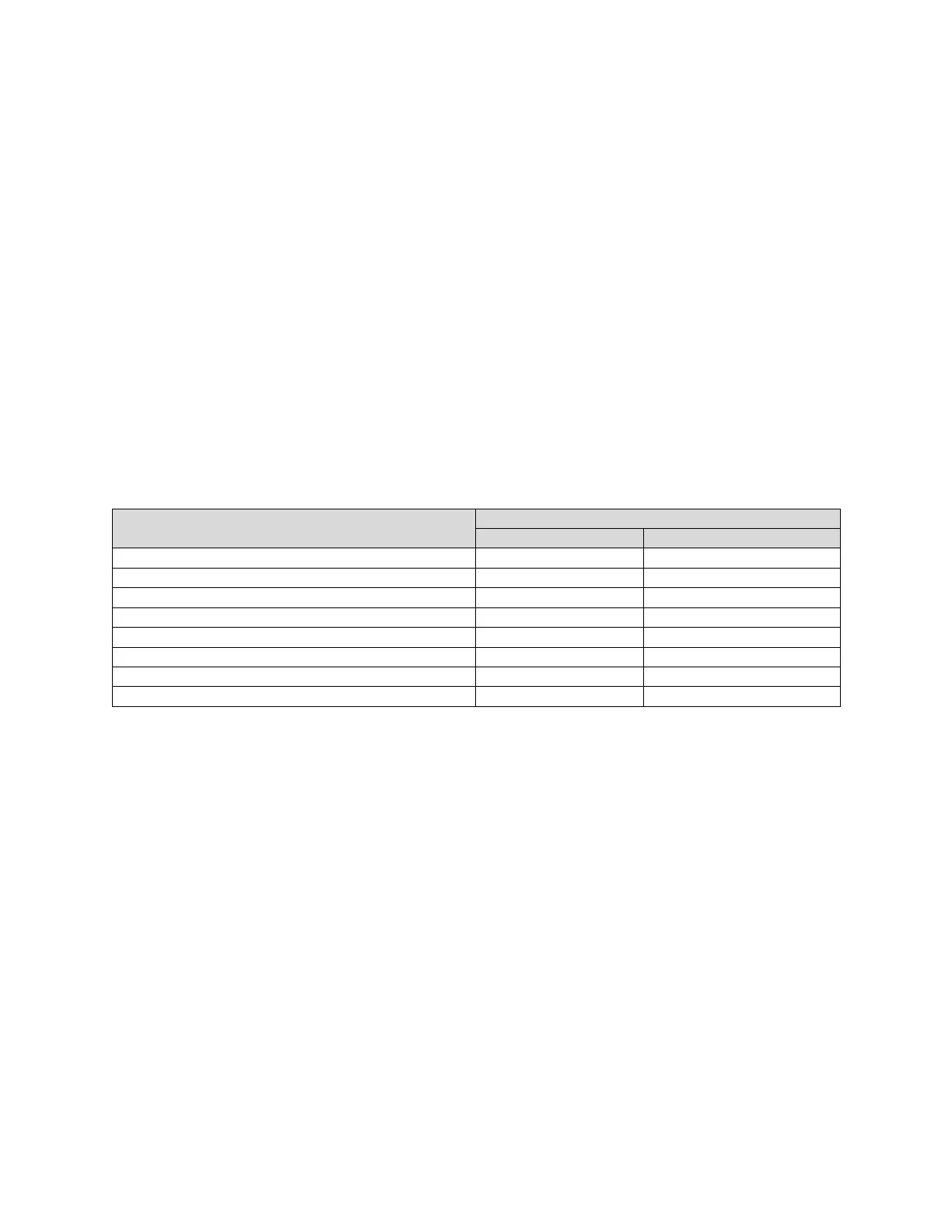

f. Compare the nitrogen production flow rate with the nitrogen production values listed in the

following chart.

Nitrogen Generator Flow Rates

Production Rate – SCFH (L/min)

AG-675 Wall Mount w/ Integral Air Compressor

AG-950 Wall Mount w/ Integral Air Compressor

AG-2000 Wall Mount w/ Integral Air Compressor

AG-3500 Wall Mount w/ Integral Air Compressor

AG-6500 Stand Alone w/ 7.5 hp Air Compressor

AG-11000 Stand Alone w/ 7.5 hp Air Compressor

AG-18500 Stand Alone w/ 7.5 hp Air Compressor

AG-22500 Stand Alone w/ 10 hp Air Compressor

NOTES: If production flow rate is lower than flow rates in the production chart, check pressure regulator

of the excess bleed off assembly.

If production flow rate identified and documented varies more than 10% of the flow rates in

the production chart, contact ECS.

NITROGEN GENERATOR SHORT CYCLING PREVENTION PROCEDURE

In situations where the nitrogen generator experiences short cycling, the short cycling is typically the

result of an erratically operating air maintenance device (AMD). Installations where the AMD doesn’t close

properly or partially closes, the nitrogen supply line pressure increases to the cut-out (turn-off) pressure

of the nitrogen generator before the sprinkler systems being supplied are at the proper operating

pressure. Because one or more of the supplied systems did not reach the proper operating pressure when

the nitrogen generator shuts off. The nitrogen supply line depressurizes through the AMD into the

sprinkler system(s). This depressurization allows the supply line pressure to fall below the cut-in (turn-on)

pressure of the nitrogen generator resulting in the nitrogen generator turning on. The process of filling

the nitrogen supply line is repeated.

Loading...

Loading...