75

TROUBLESHOOTING

Safety Warning

Only qualified personnel can perform inspection, testing and maintenance of the nitrogen generation

equipment. Prior to any system troubleshooting on the nitrogen generation system, ensure that the

nitrogen generator is isolated from the compressed air supply and all system risers. Be aware of

pressurized system components as some of the troubleshooting procedures require system components

to be pressurized. Failure to do so can result in system damage and/or personal injury.

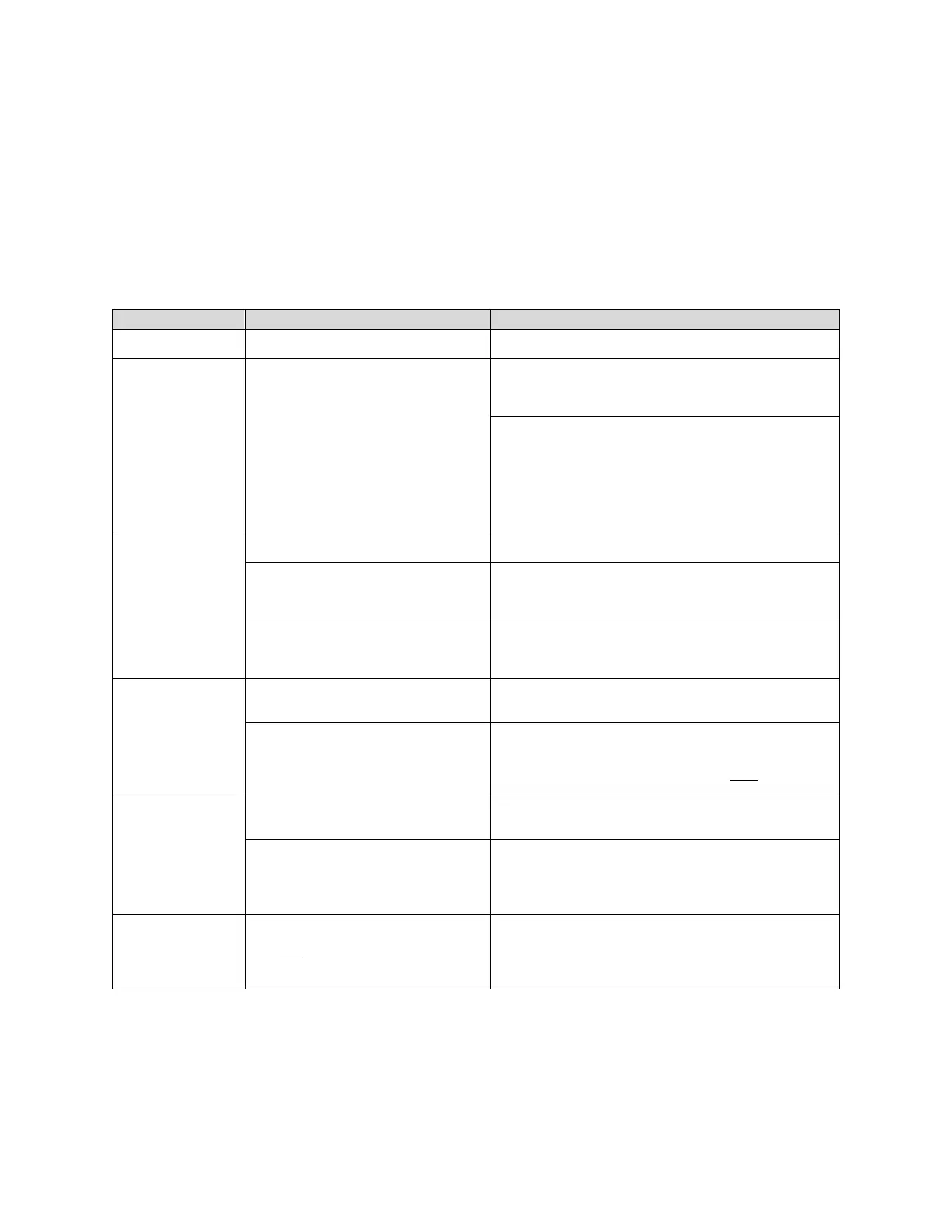

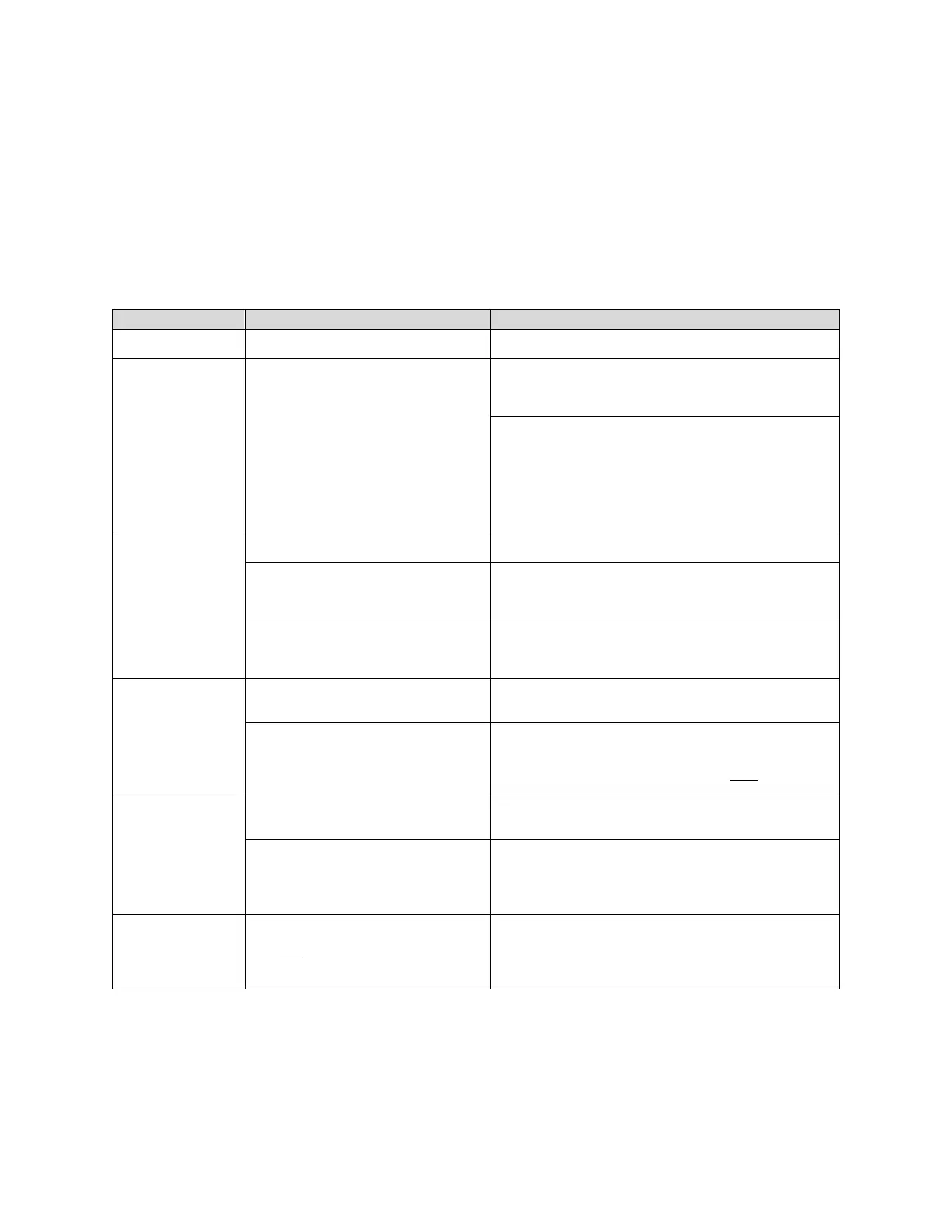

Nitrogen generator not

running.

No lights or indicators on generator.

Check incoming power and fuses in nitrogen generator.

Nitrogen generator not

running.

Generator lights and indicators on.

The nitrogen generator may be in the depressurizing phase of the

breathing cycle. When sprinkler system reaches the generator

cut-in pressure, the nitrogen generator will automatically turn on.

(normal operation).

Check status of solenoids in generator.

• Solenoids should be energized (LED on) when running

Check system pressure:

• If system pressure above cut-in pressure of generator, reduce

system pressure below cut-in pressure and check generator

operation.

• If system pressure below cut-in pressure of generator, check

power to air compressor.

Nitrogen not flowing in

sprinkler system.

Verify nitrogen generator is not in bypass

mode.

Place nitrogen generator in nitrogen generation mode.

While the nitrogen generator running, use a gas

analyzer to measure the nitrogen output

quality. (See Commissioning and Maintenance

Sections).

If the nitrogen reading is below 97%, contact ECS.

While the nitrogen generator running, measure

generator production flow rate through flow

meter. (See Commissioning and Maintenance

Sections).

Compare generator production rate to system commissioning

documentation and/or factory test report. If significantly lower,

contact ECS.

Nitrogen generator is

short cycling.

Pressure on generator HMI display decreases

after generator shuts off with sprinkler system

air maintenance device (AMD) open.

Close inlet to sprinkler system AMD, if pressure continues to

decrease, check for leaks in generator cabinet and supply line.

With AMD closed, the pressure on generator

HMI display remains constant after generator

shuts off.

• AMD partially opening allowing minimal nitrogen flow to sprinkler

system results in generator short cycling. Adjust, repair or replace

AMD as necessary.

• Verify the AMD pressure is 3-5 psig (.2-.3 bar) above nitrogen

generator cut-in pressure. Adjust as necessary.

Air compressor is short

cycling.

Air compressor short cycles with the nitrogen

generator in the standby mode.

• Check supply line from air compressor to nitrogen generator for

leaks.

• Check filter floats in filter housings not sealing properly.

Nitrogen generator remains on while air

compressor short cycles.

• Verify the excess air regulator pressure is set 5-10 psig (.3-.7) below

air compressor cutout pressure. Adjust as necessary. Air

compressor should continue to operate until nitrogen generator

shuts off. (See Commissioning and Maintenance Sections).

• Verify production flow rate and nitrogen purity levels.

Nitrogen generator

running continuously or

running more than four

(4) hours

Generator in nitrogen generation mode with

AMD open and unable to pressurize sprinkler

system.

Close AMD.

• If system supply line pressurizes, check sprinkler system for

leaks or inoperable AMD (AMD not automatically closing).

• If system supply line does not pressurize, check nitrogen

generator and system supply line for leaks.

Loading...

Loading...