© Edwards Limited 2018. All rights reserved. Page 3

Introduction

A732-01-880 Issue D

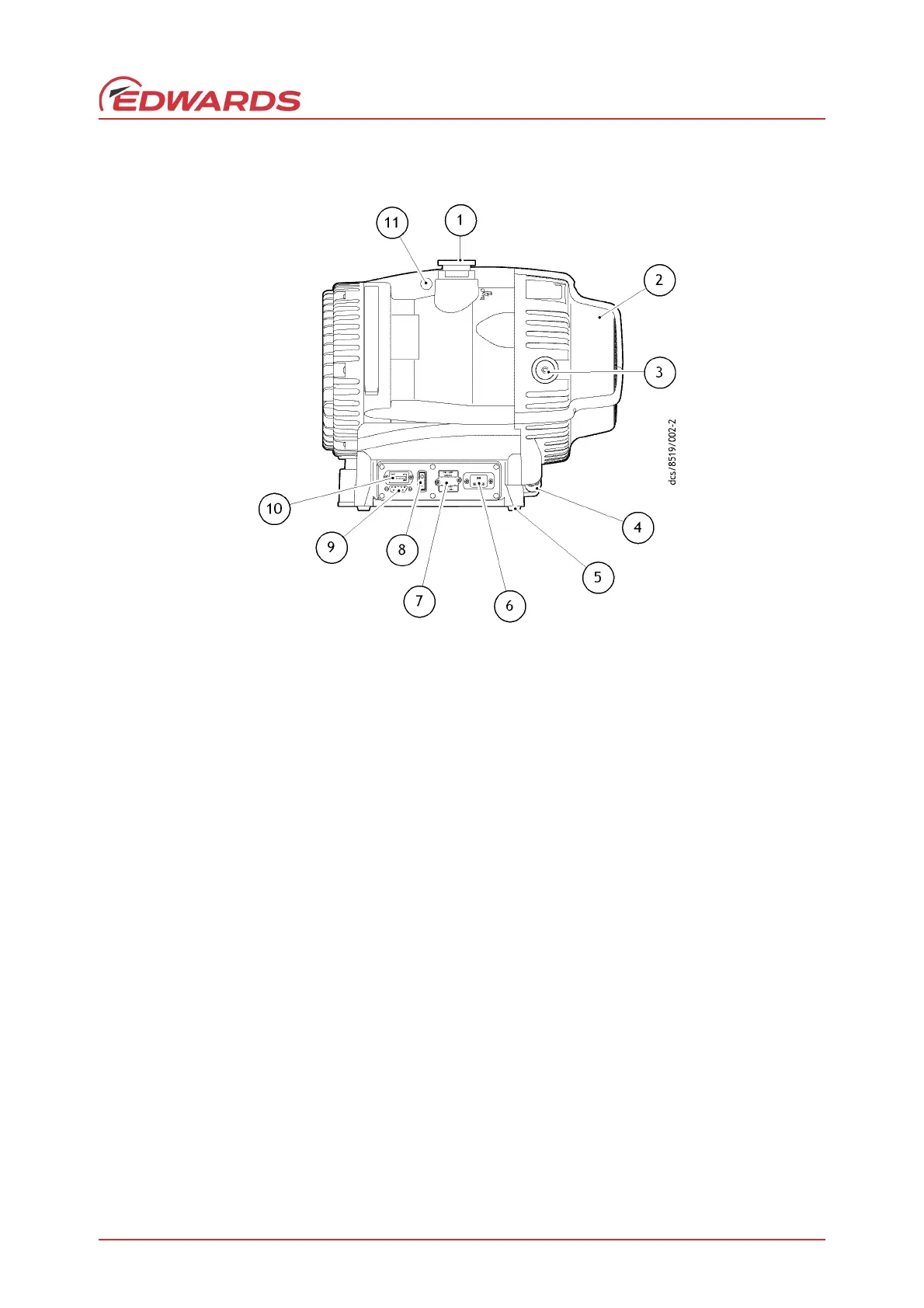

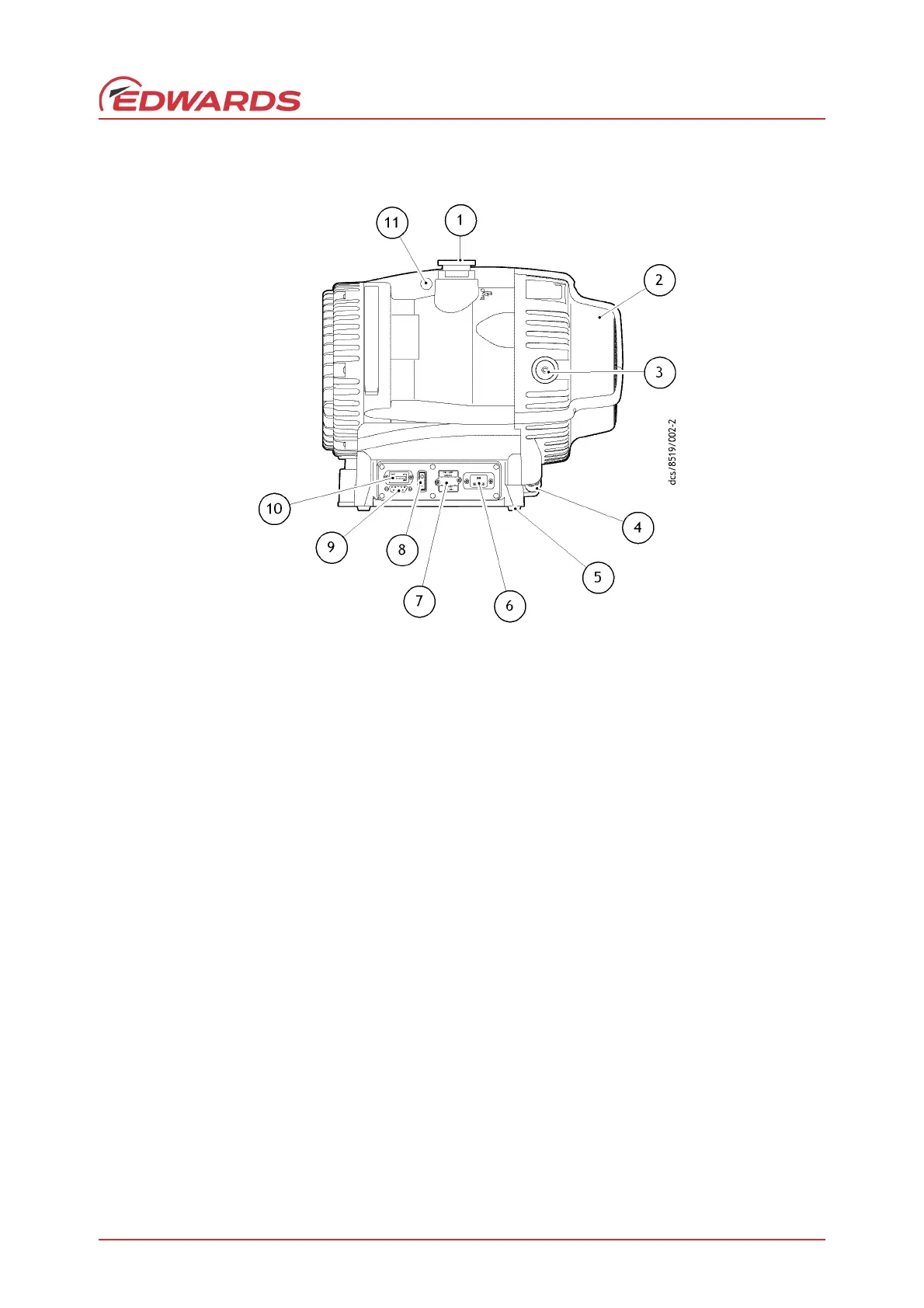

Figure 1 - XDS100B scroll booster

1.3 Description

The XDS100B Scroll Booster is shown in Figure 1. Refer to Figure 1 for item numbers in brackets in the following

descriptions.

The XDS pump is a compact, reliable vacuum pump which is suitable for use on vapour handling processes. The

XDS100B is a scroll booster, with a pumping mechanism designed specifically for high pumping speed. It cannot

exhaust directly to atmosphere, and must be backed by a primary pump; it is intended for use in conjunction with

Edwards XDS35i or XDS46i scroll pumps.

The body of the pump includes a fixed scroll and an orbiting scroll. The orbiting scroll is controlled by the electric

motor through an eccentric cam on the motor drive shaft. The movement of the orbiting scroll, meshed with the

fixed scroll, forms successive crescent shaped volumes in the pump. Gas that enters the pump through the inlet is

compressed by the movement of the orbiting scroll and swept towards the centre of the fixed scroll. The compressed

gas enters the exhaust port near the centre of the stationary scroll and is exhausted from the pump through the

outlet, which must be connected to a primary pump.

The XDS is a truly dry vacuum pump, as all the bearings, with hydrocarbon lubricant, are isolated from the vacuum

space.

The pump mechanism is driven directly by a three phase electric motor. The motor is controlled by an inverter,

which manages the supply of current to the motor in accordance with operating conditions, and allows the pump

to be connected to a single phase supply. The voltage changeover switch, beneath the voltage changeover switch

cover, (7) must be set to the correct position in accordance with the power supply being used, refer to Section 3.5.2.

1. NW40 inlet port

2. Cooling fan

3. NW40 exhaust port

4. Fan connector

5. Rubber feet

6. Electrical connector

7. Voltage changeover switch cover

8. Run/Standby switch

9. 15-way connector

10. Hour counter

11. Lifting eye

Loading...

Loading...