15

13.0 Fault Finding

Fault Finding

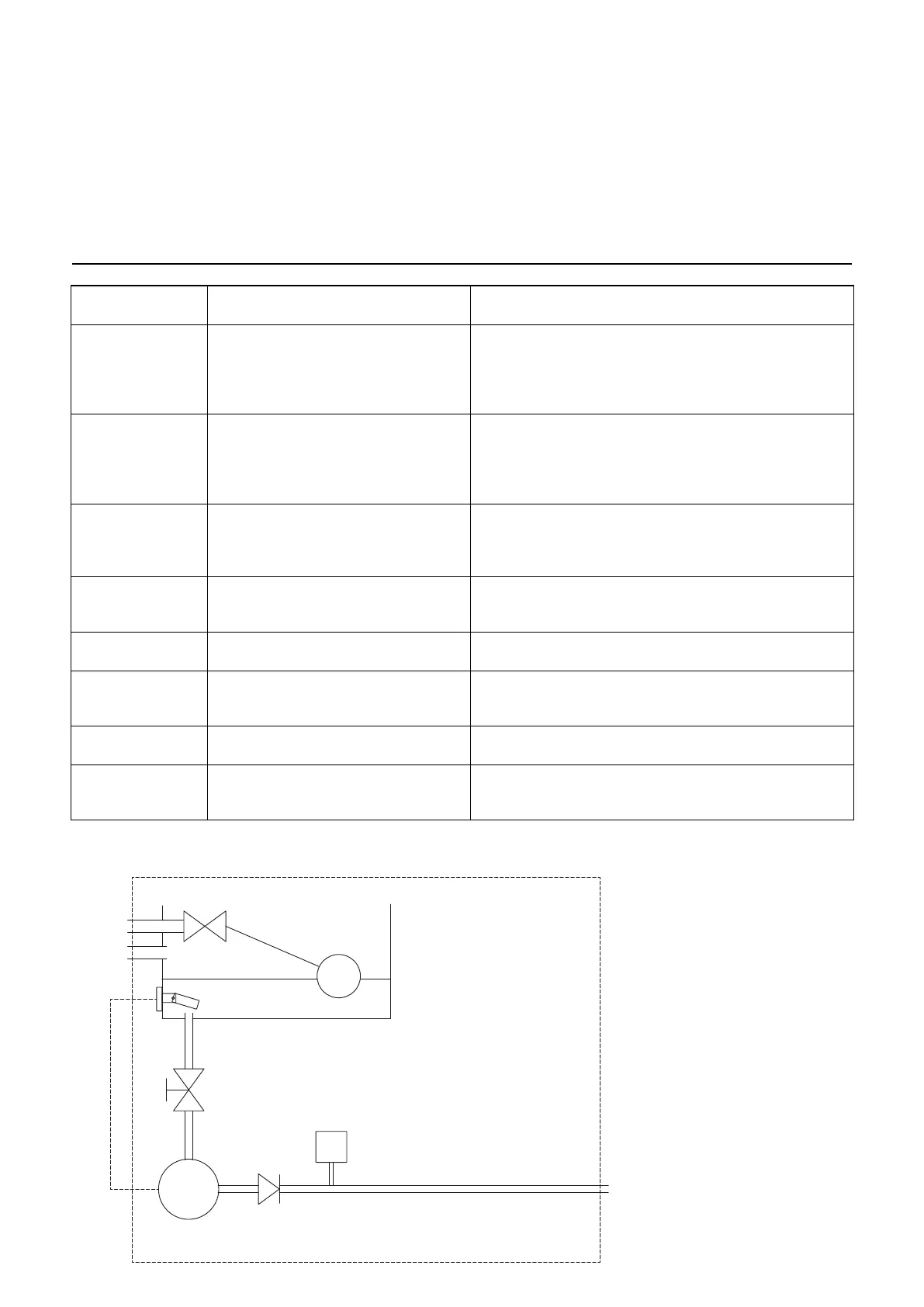

Fault Possible Cause Action

Pump will not run • Unit up to pressure

• No power to unit

• Isolator fuse blown

• Cut in pressure set incorrectly

• Pump seized or faulty

• None

• Check at source

• Replace fuse. Note – investigate the cause of the blown fuse

• Adjust cut in pressure

• Service or replace pump

Pump runs but will

not build up

pressure

• Pump isolating valve closed

• Pump not primed

• Float switch faulty

• Pump non return valve jammed

• Blocked flow restrictor

• Open valve

• Prime pump

• Check water level and replace float switch

• Check valve

• Check flow restrictor for blockage

Pump cuts in & out

rapidly

• Value of cut in and cold fill pressure set

incorrectly

• Non return valve not sealing correctly

• System leak

• Adjust values

• Clean valve seat or replace valve if necessary

• Trace leak and ensure system is sound

Pump runs

continuously

• Value of cold fill pressure set incorrectly

• Pump relay faulty

• System leak

• Adjust value

• Replace faulty relay pcb in grey box

• Trace leak and ensure system is sound

Pump cuts out at

wrong pressure

• Pressure gauge is inaccurate

• Internal pressure sensor faulty

• Replace pressure gauge

• Replace pressure sensor

Maximum system

working pressure is

too high

• Cold fill pressure set incorrectly

• Internal pressure sensor faulty

• Adjust value

• Replace pressure sensor

Boiler switches off

unexpectedly

• Hi or Lo pressure alarms set incorrectly

• Safety circuit is wired incorrectly

• Adjust values

• Check wiring against wiring diagram

System pressure

runs consistently at

cold fill pressure

• Small system leak

• Trace leak and ensure system is sound

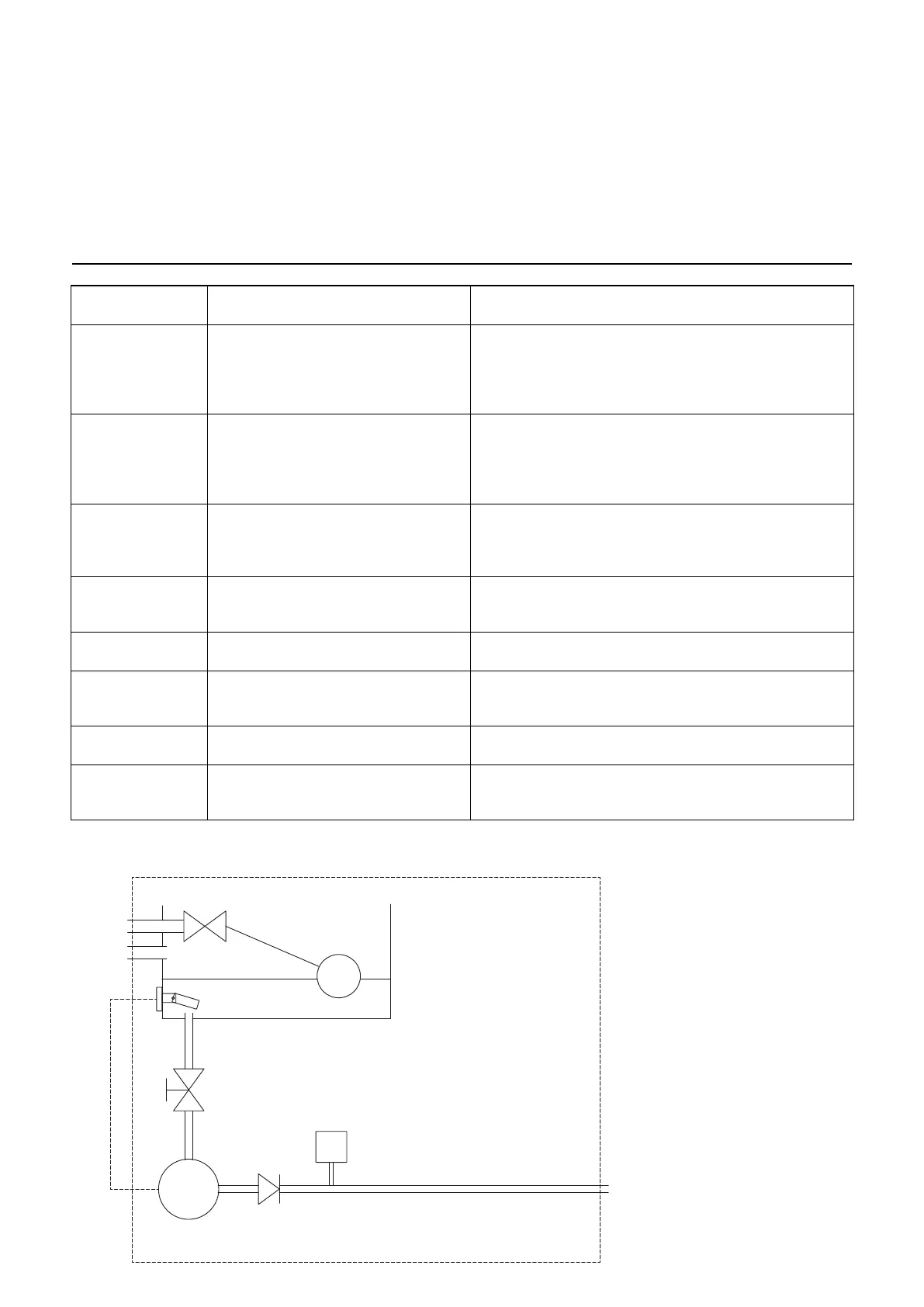

Figure 12 – Controls Schematic

COLD WATER

INLET

OVERFLOW

BALL VALVE

LOW LEVEL ALARM

ISOLATING VALVE

NON

RETURN

VALVE

PUMP

0.7HP

2.8A

PRESSURE

SENSOR

PRESSURISATION UNIT

TO SYSTEM

Loading...

Loading...