12

12.0 Maintenance & Commissioning Menu

Maintenance & Commissioning Menu

The maintenance & commissioning of

the pressurisation unit shall only be

undertaken by a competent person,

as various safety items associated

with the safe operation of the heating

cooling / chilled water system need

to be checked and confirmed. It

is therefore recommended that a

qualified Gas Safe registered engineer

undertake these works.

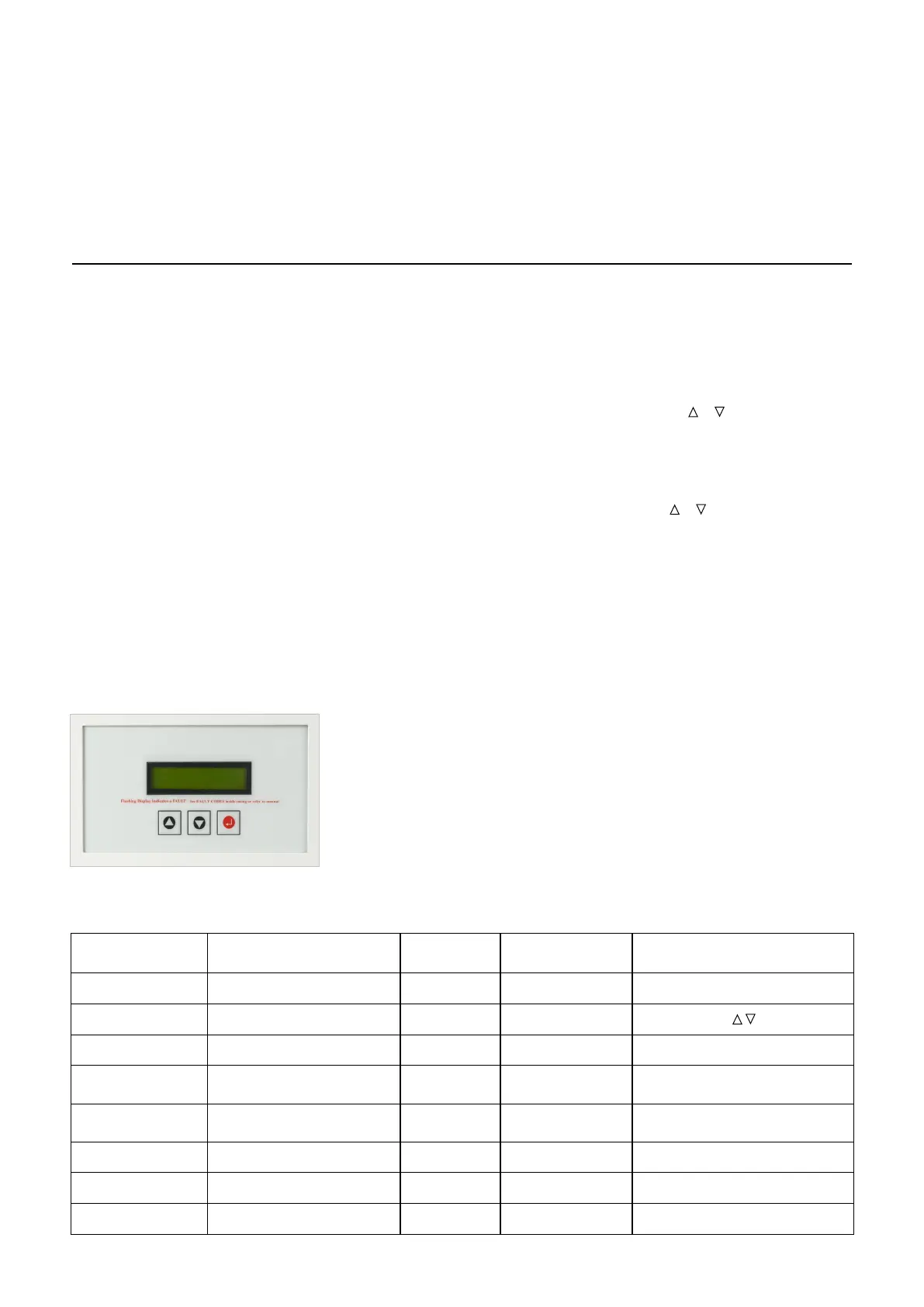

12.1 Control Panel

The Control Panel can be accessed

with the case On or Off, and has

two access levels, Standard &

Maintenance. These levels can be

accessed using the UP, DOWN and

ENTER buttons.

Standard Menu – For the End User.

Maintenance Menu – For the

Commissioning / Service Engineer.

12.2 Standard Menu

When the POWER supply has been

turned ON to the appliance, the LCD

will display the STANDARD MENU, as

detailed below. Review of the ID Lines

is done by using the UP or DOWN

buttons.

Please note, COLDFILLPRES is the

only ID line that can be altered at this

level, all other data displayed is

READ ONLY.

Note*: the pump fitted to the unit

is capable of a maximum Cold Fill

pressure of 3.0 bar

The procedures detailed in Sections

10 & 11 above shall be completed

prior to commissioning and to ensure

safe operation of the equipment prior

to hand over.

The appliance is factory set, and

should not require many adjustments,

other than those required to suit the

particular requirements of the system,

such as COLD FILL PRESSURE, and

HIGH / LOW WATER PRESSURE

ALARMS.

To review / alter the operational

settings, the MAINTENANCE MENU

of the micro-processor needs to

be accessed, by undertaking the

following procedure:

1) Turn ON the Mains Power Supply;

2) Press and

& Program Buttons

simultaneously for 5 seconds. The

screen will display USER MENU ON

or USER MENU OFF depending on

the previous menu setting.

Using the

& buttons, parameters

can be reviewed or adjusted as

appropriate.

To amend a Parameter, select the

ID Line required, Press the ENTER

button, to select that parameter, then

use the UP or DOWN buttons to

change the value, and then Press the

ENTER button to confirm the change.

To return to normal operation, turn

OFF the Mains Power supply, wait 30

seconds, then turn ON

the Mains Power supply.

Figure 12.1 – Fascia Panel

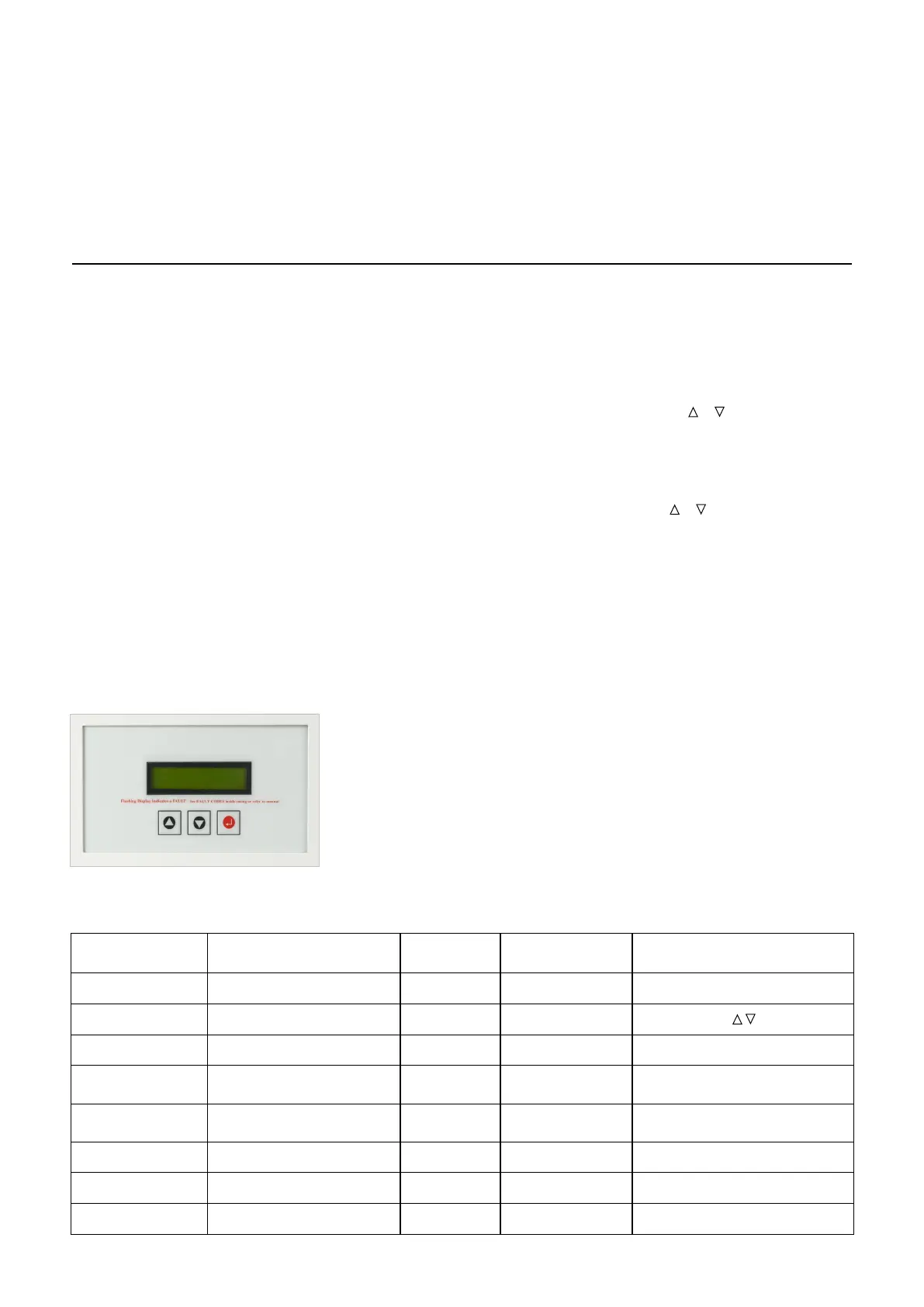

ID line Description Range Factory Default Comments

SYSTEM PRES Current System Pressure

0-6.0bar ** Actual value - Review only

COLDFILLPRES

Cold Fill Pressure (pump cut-out)

0.7-3.4bar 1.8bar

Can be altered

MAKE-UP V0

Volume of Water Introduced

0-9999 L *** Actual value - Review only

MAKE-UP ALARM

Water Introduction Alarm

00-99L 99

Review only. Review only

Actual volume=XX*10 L

MAKE-UP V2

Volume of Water Introduced

(since last rest)

0-999.9 L *** Actual value - Review only

PUMP OPS

Number of pump cycles

0-9999 *** Actual value - Review only

PUMP1 HRS

Hours operation of pump1

0-99.59 **:** Actual value - Review only

PUMP2 HRS

Hours operation of pump2

0-99.59 **:** Actual value - Review only

Loading...

Loading...